- Joined

- Aug 5, 2018

- Location

- Bellerose Manor, NY

Morning all,

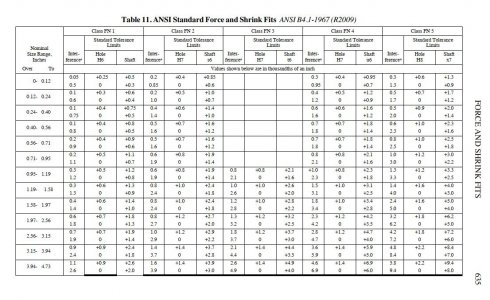

How much larger should the diameter of a 6061 aluminum shaft be to allow a press fit into the same 6061 aluminum?

Thanks in advance.

Michael

How much larger should the diameter of a 6061 aluminum shaft be to allow a press fit into the same 6061 aluminum?

Thanks in advance.

Michael