- Joined

- Dec 7, 2015

- Messages

- 519

I need to reassemble the spindle pulley on my drill press. I'm a little confused about the order of operations when pressing bearings into "blind" positions.

Let me explain:

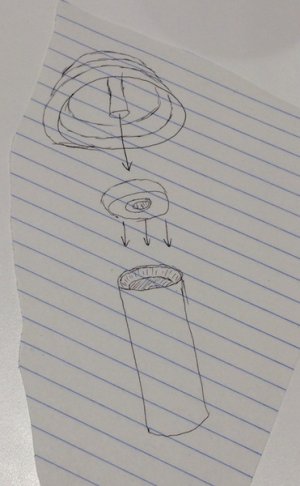

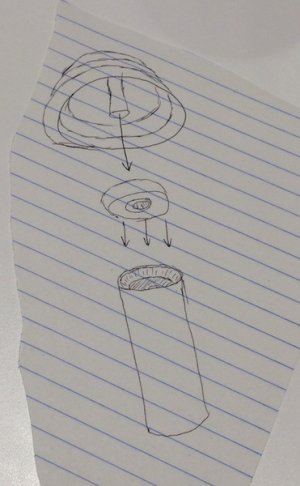

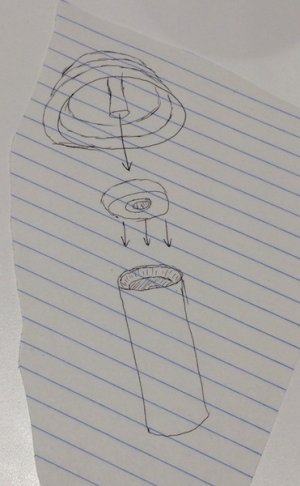

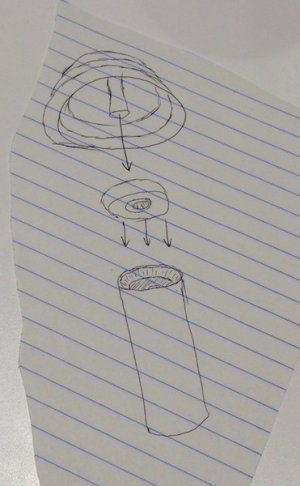

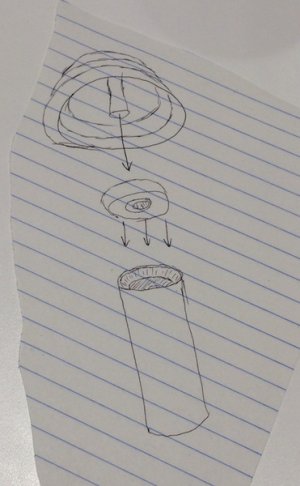

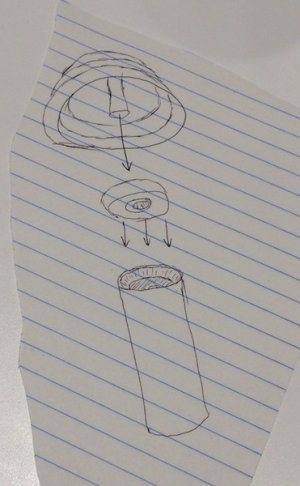

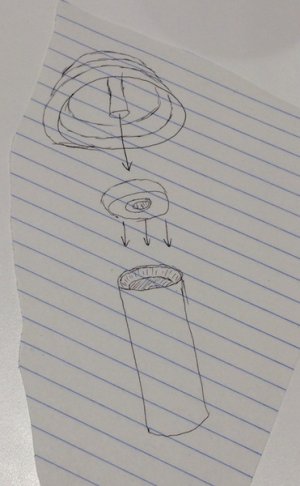

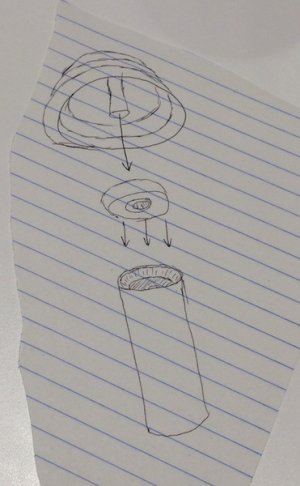

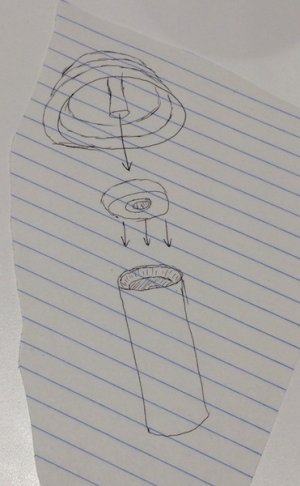

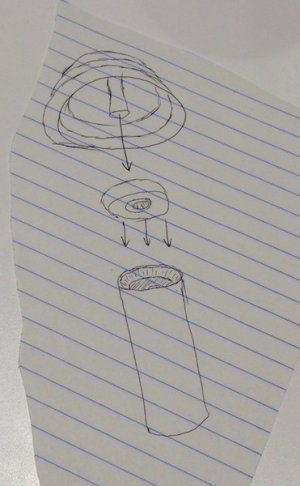

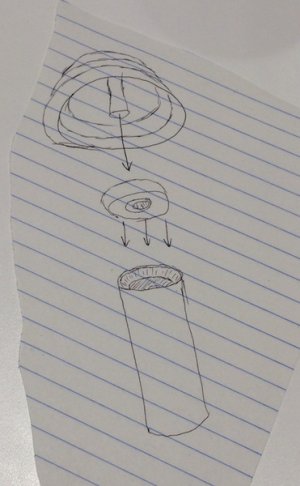

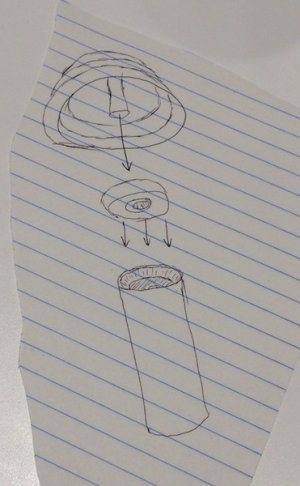

But for my spindle pulley, the bearing is pressed onto a shaft molded into the pulley, and also pressed into a housing on the drill press head itself:

Now, when I took the drill press apart, the service manual stated to drive the pulley off by striking the bearings from inside the head. This caused the pulley to come off with the bearings intake. I wonder if this would imply that I should press the bearings onto the shaft of the pulley, and then press the assembly into the housing in the drill press head?

I'm new to this stuff. If there is some reference (Machinist's Handbook?) that defines the proper order of operations for this kind of assembly- I'd like to know about it. Any advice would be appreciated.

Let me explain:

- If you are pressing a bearing into a housing (like a car hub and wheel bearing) I know that you'd want to make sure to push on the outside race since that is coming into contact with the hub.

- Similarly, if you are pressing a bearing onto a shaft, I know that you'd want to push on the inside race since that is coming into contact with the shaft.

- You never push on the race that isn't coming into contact with the surface your installing the bearing into.

But for my spindle pulley, the bearing is pressed onto a shaft molded into the pulley, and also pressed into a housing on the drill press head itself:

Now, when I took the drill press apart, the service manual stated to drive the pulley off by striking the bearings from inside the head. This caused the pulley to come off with the bearings intake. I wonder if this would imply that I should press the bearings onto the shaft of the pulley, and then press the assembly into the housing in the drill press head?

I'm new to this stuff. If there is some reference (Machinist's Handbook?) that defines the proper order of operations for this kind of assembly- I'd like to know about it. Any advice would be appreciated.