- Joined

- Jul 20, 2012

- Messages

- 1,238

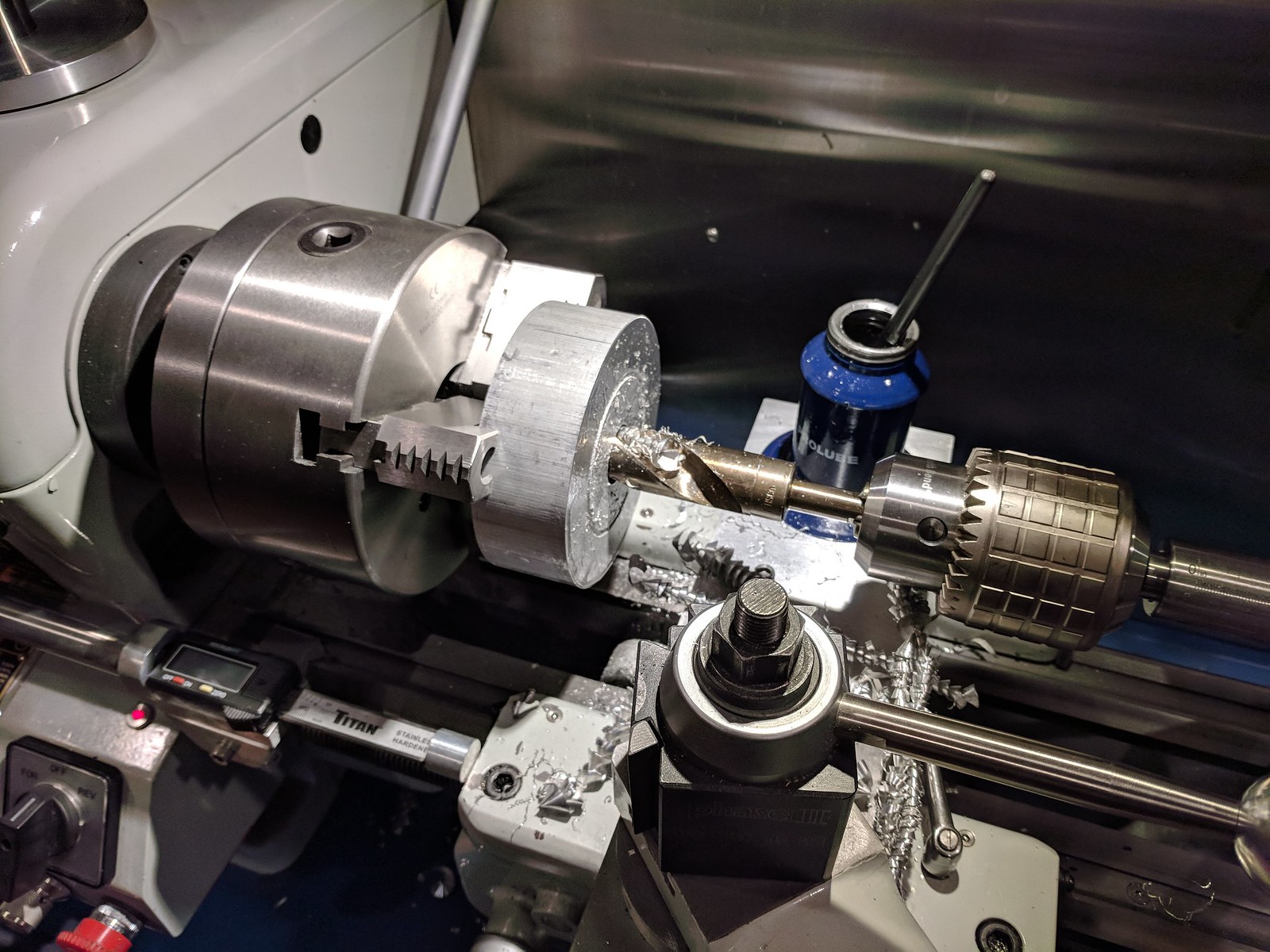

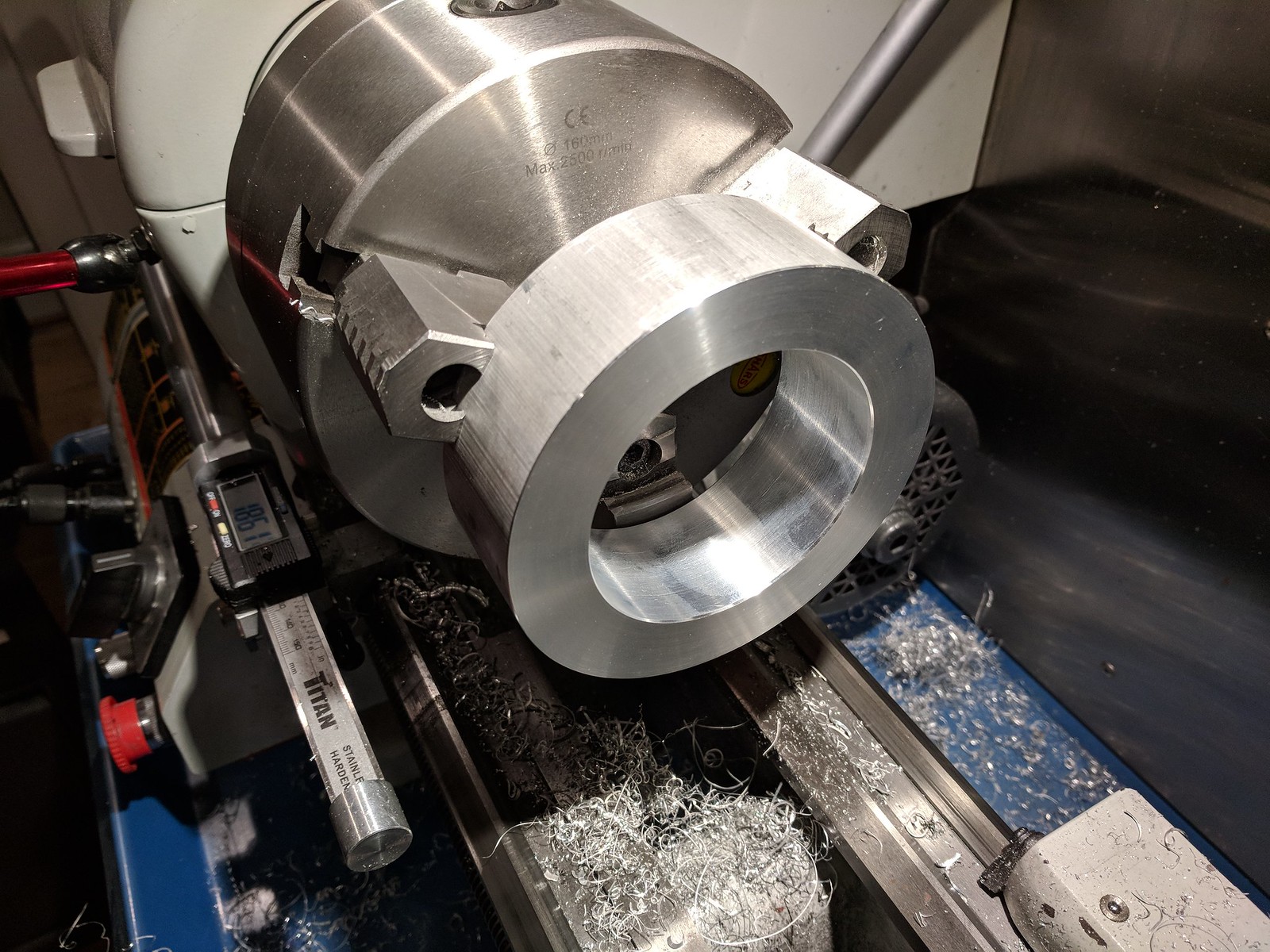

Better to bore it. With the wood working hole saw it won’t leave a good finish anyway and you would bore it to clean up the hole.

That appears to be a metal cutting hole saw, but yes, boring would be better, or in addition to (after) the sawBetter to bore it. With the wood working hole saw it won’t leave a good finish anyway and you would bore it to clean up the hole.

Thanks guys. I have a large Jacobs Superchuck that I could use also rather than keyless. A tang would be useless since the tailstock has no slot. My drill press has a slot! Heck I think I will go that route.

Robert