- Joined

- Dec 18, 2019

- Messages

- 6,456

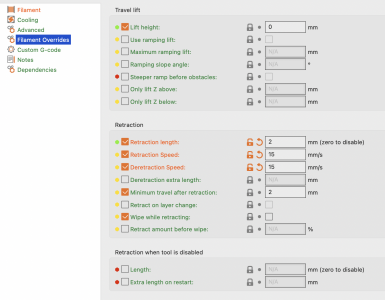

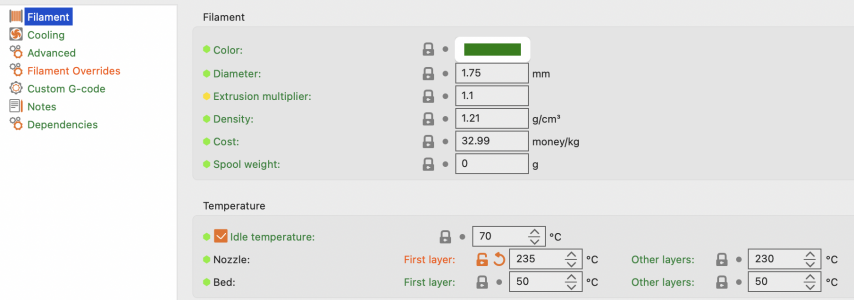

I kept the standard retraction lengths for fear of jamming. PETG is trivially easy compared to TPU. I can use defaults on PETG and it comes out beautiful as long as it's dry. My first roll of PETG was soggy and snapped and popped right out of the package. Learned about filament drying that day!Have you tried filament and zhop retraction (distance inputs)? I believe those were some suggestions with my stringing PETG.

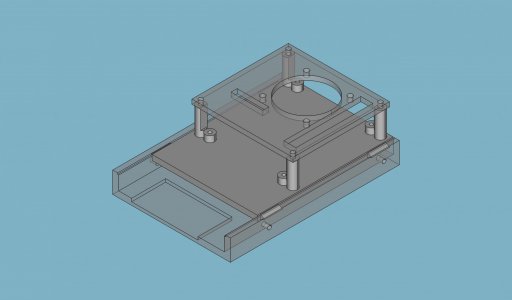

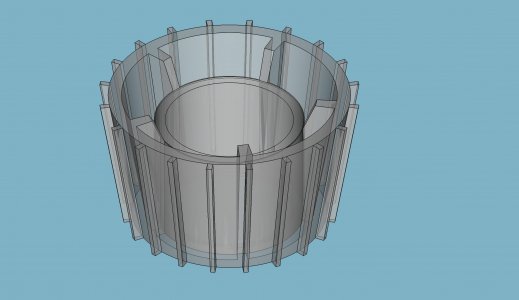

My short run models in TPU are mostly ok with not too much stringing. But the longer, bigger model has quite a bit, so much that initially I couldn't see through the bore of the part.