Hello,

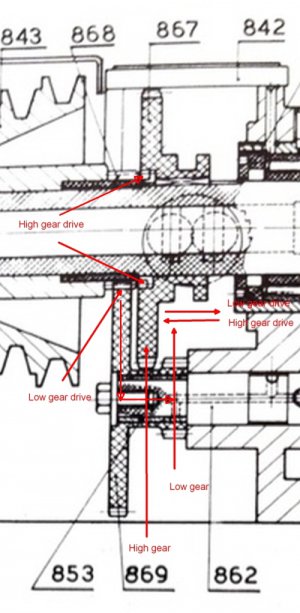

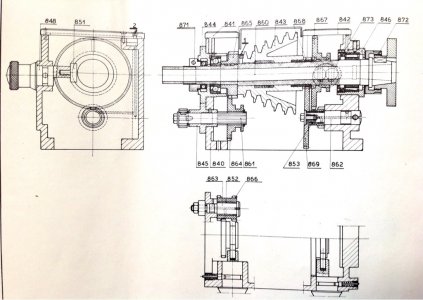

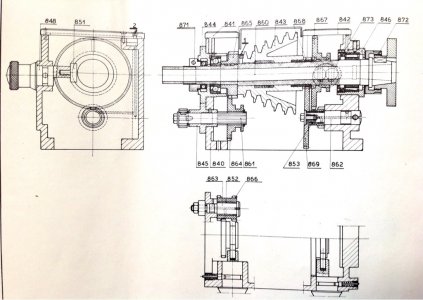

I have a problem with the high/low speed selection from my AVM AS125 lathe.

While I was working on my lathe in low speed suddenly the spindel of the headstock blocked. After checking what happend I found that I can't select high/low speed anymore, the selector switch is working fine, and the sprocket can move freely.

When I now select low speed the spindel is blocked. I have opened the the headstock but can't find anything broken or wrong, has anybody experienced this before, or does anyone know how I can solve this problem ? I'll ad the drawing of my headstock maybe it will help.

Regards Marc.

Sent from my iPhone using Tapatalk

I have a problem with the high/low speed selection from my AVM AS125 lathe.

While I was working on my lathe in low speed suddenly the spindel of the headstock blocked. After checking what happend I found that I can't select high/low speed anymore, the selector switch is working fine, and the sprocket can move freely.

When I now select low speed the spindel is blocked. I have opened the the headstock but can't find anything broken or wrong, has anybody experienced this before, or does anyone know how I can solve this problem ? I'll ad the drawing of my headstock maybe it will help.

Regards Marc.

Sent from my iPhone using Tapatalk