- Joined

- Dec 31, 2011

- Messages

- 41

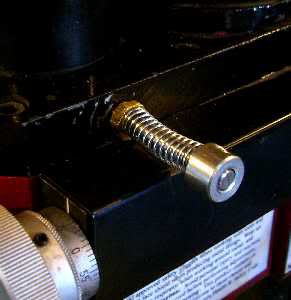

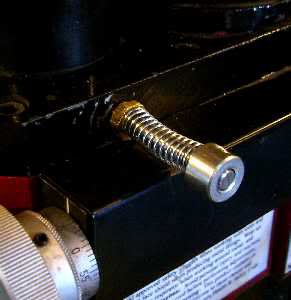

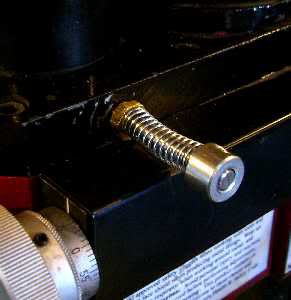

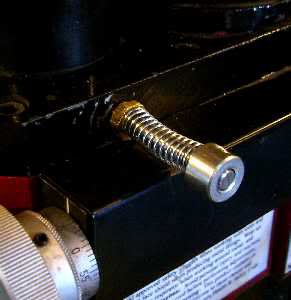

I have done several projects FOR my mini mill that some may find useful. Today I will show the spindle stop I made. This stop can be installed with NO dis assembly required. The existing access hole is such that it can be tapped with one of three taps. 3/8-24, 10mm or 1/8" pipe. You need about 1/4" of threads and they do not need to be quality threads for this project.

Starting with a 2 5/8" length of 5/16" round stock, I turned 2" of it to 1/4". I made a small flat on the end for the grub screw of a 1/4" set collar. Digging through my junk box I found a suitable spring with a id of slightly over 1/4" and 1 3/4" long. Next I found a brass fitting for copper tubing that had 1/8" pipe threads.

Using a 1/8 pipe tap I tapped the access hole about 1/4" deep. This hole being in cast iron I tapped it dry and used a small bar magnet to remove all the cuttings. Next I assembled the stop and threaded it into the tapped hole.

Here is the next project. I will post the details soon.

Mill Light

Joe

Starting with a 2 5/8" length of 5/16" round stock, I turned 2" of it to 1/4". I made a small flat on the end for the grub screw of a 1/4" set collar. Digging through my junk box I found a suitable spring with a id of slightly over 1/4" and 1 3/4" long. Next I found a brass fitting for copper tubing that had 1/8" pipe threads.

Using a 1/8 pipe tap I tapped the access hole about 1/4" deep. This hole being in cast iron I tapped it dry and used a small bar magnet to remove all the cuttings. Next I assembled the stop and threaded it into the tapped hole.

Here is the next project. I will post the details soon.

Mill Light

Joe