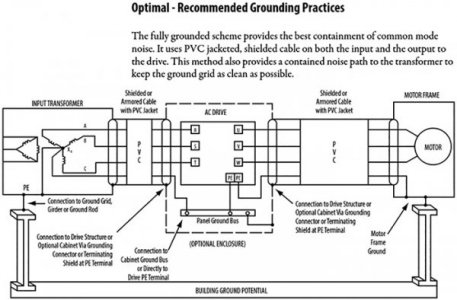

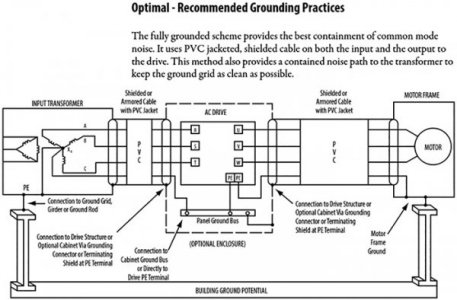

Salutations electrically minded folks. I posted a pic of my workshop, and to my surprise Richard King replied, he asked if everything was properly grounded. Hmmm, I did not know (didn't inherit the electrician gene from dad). My VFD is only grounded via the ground supplied through the 220 socket. The motors are frame grounded. Is it recommended that there be a second earth ground directly from the machine per the below diagram?