Welp, I just bought a DRO for the lathe so I guess I just created even more work for myself! :rofl: Anyway, this is the one that I picked:

http://dropros.com/DRO_PROS_Lathe_Digital_Readout.htm#DRO_PROS_2L

Anyone have any tips for a DRO newbie? FWIW, it's going on a 14x40 Vectrax/Turnpro generic Tiawanese lathe. If this one works out well enough, I'll stick another one on my mill. My plan was to go with the iGaging units from DavidH, but I was concerned about the accuracy and also the display size since I'm so stinkin' blind. I looked at a bunch of different options including China-based companies and used displays, but 90+% of the used ones don't have scales, and if they do, they're the wrong size or damaged, and the Chinese companies just give me a bad feeling. thedrostore.com took two days to answer my email concerning scale sizing so I hate to think about a warranty issue.

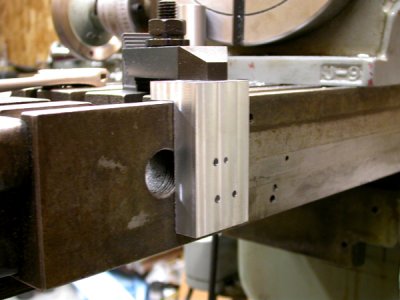

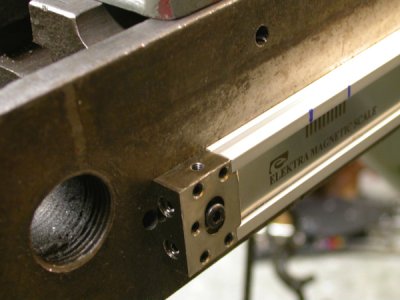

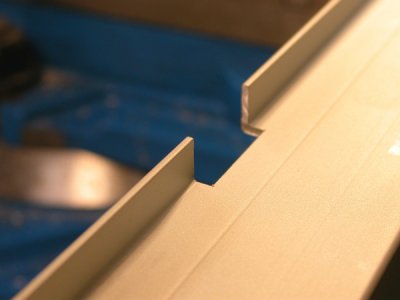

Installation pics and a review to follow...:thinking:

http://dropros.com/DRO_PROS_Lathe_Digital_Readout.htm#DRO_PROS_2L

Anyone have any tips for a DRO newbie? FWIW, it's going on a 14x40 Vectrax/Turnpro generic Tiawanese lathe. If this one works out well enough, I'll stick another one on my mill. My plan was to go with the iGaging units from DavidH, but I was concerned about the accuracy and also the display size since I'm so stinkin' blind. I looked at a bunch of different options including China-based companies and used displays, but 90+% of the used ones don't have scales, and if they do, they're the wrong size or damaged, and the Chinese companies just give me a bad feeling. thedrostore.com took two days to answer my email concerning scale sizing so I hate to think about a warranty issue.

Installation pics and a review to follow...:thinking: