- Joined

- Mar 26, 2018

- Messages

- 8,410

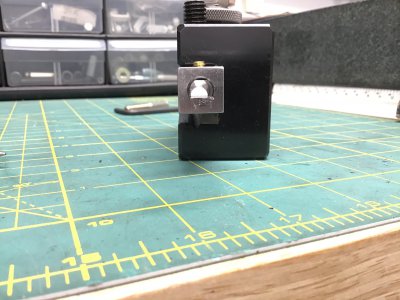

These small boring bars are great.

They are a PITA to mount in the holder.

I know Micro sells these and yes I’m sure they look better than mine but it works great.

I’ll either grind down the set screws or leave them alone.

It works just fine as shown.

Drilled and reamed to .001” over size. Fits real good.

They are a PITA to mount in the holder.

I know Micro sells these and yes I’m sure they look better than mine but it works great.

I’ll either grind down the set screws or leave them alone.

It works just fine as shown.

Drilled and reamed to .001” over size. Fits real good.