- Joined

- Jun 26, 2013

- Messages

- 191

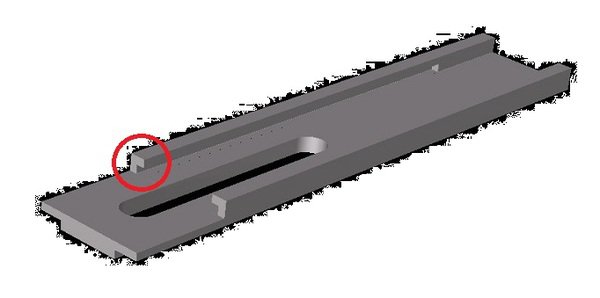

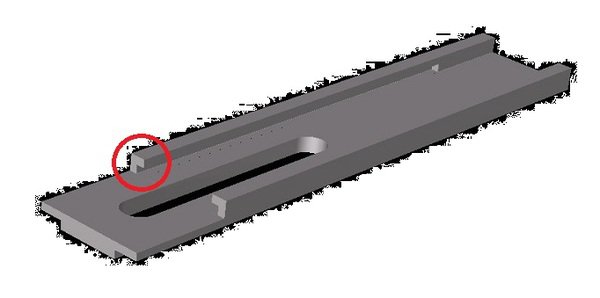

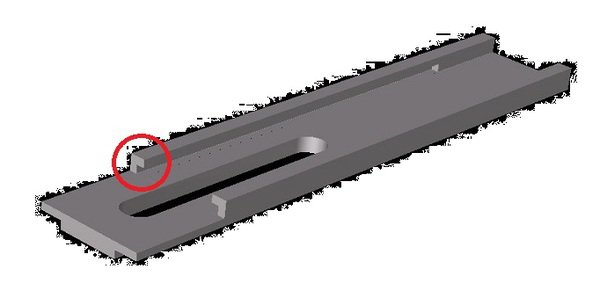

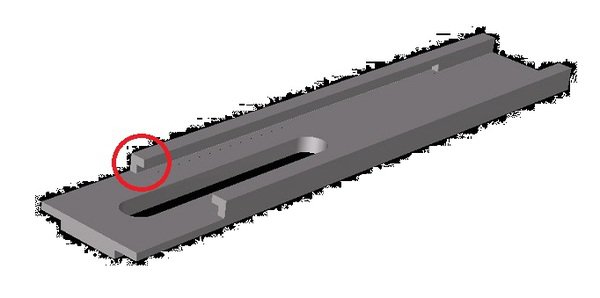

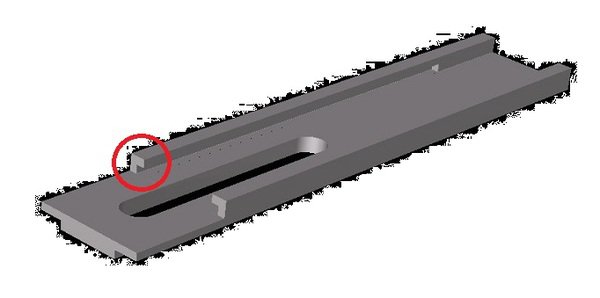

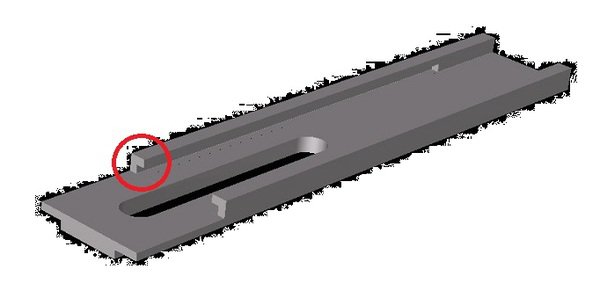

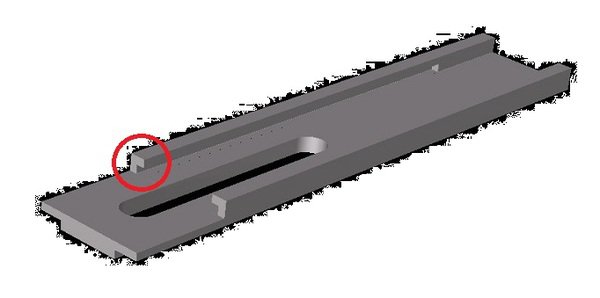

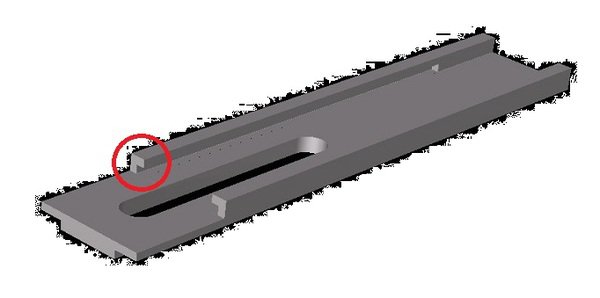

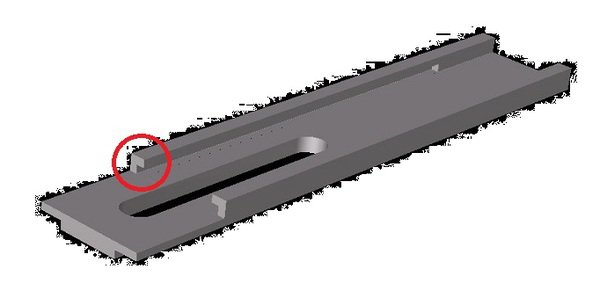

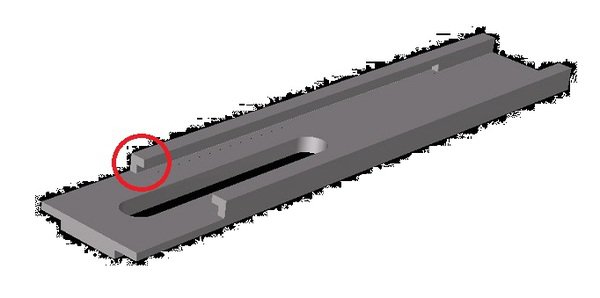

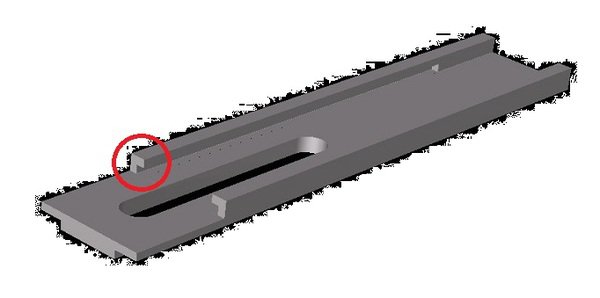

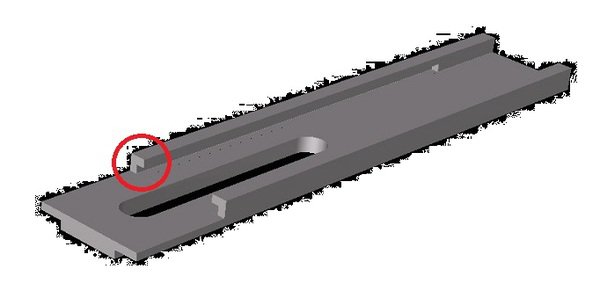

Hi All - I'm making a part and have a need to mill a couple of slots into a piece of CRS. The feature I'm asking about is circled in pic below...

The slot is .125" deep and .125" tall.

I was thinking I'd have to buy a slot-cutting end mill, but when I go to look for them, I can't seem to find anything appropriate. I can find 3mm and 4mm metric cutters. 4mm is too tall, but I guess a 3mm could work, would just have to run it through at two heights. I can also find T-slot cutters, that are in english units, but they don't go down to 1/8" (instead I found something like 9/64ths)...

If I went with the metric cutter, the shaft size is 12mm... Which (I assume) means I would also have to spring for a 12mm R8 collet (or mill holder) to hold it? Or, is 12mm "close enough" at .472" that a 1/2" collet would hold it firmly enough? My guess would be no.

I *think* another option would be to take a normal 1/2" 4-flute end mill to the grinder and grind off most of the side cutting flutes to form my own slot cutter. Bad idea?

Also, I've got about 20 inches of slot to cut -- should I expect a single cutter to last long enough for that, or should I assume I'll need a couple of cutters?

Is there something obvious I'm missing? Thanks!

The slot is .125" deep and .125" tall.

I was thinking I'd have to buy a slot-cutting end mill, but when I go to look for them, I can't seem to find anything appropriate. I can find 3mm and 4mm metric cutters. 4mm is too tall, but I guess a 3mm could work, would just have to run it through at two heights. I can also find T-slot cutters, that are in english units, but they don't go down to 1/8" (instead I found something like 9/64ths)...

If I went with the metric cutter, the shaft size is 12mm... Which (I assume) means I would also have to spring for a 12mm R8 collet (or mill holder) to hold it? Or, is 12mm "close enough" at .472" that a 1/2" collet would hold it firmly enough? My guess would be no.

I *think* another option would be to take a normal 1/2" 4-flute end mill to the grinder and grind off most of the side cutting flutes to form my own slot cutter. Bad idea?

Also, I've got about 20 inches of slot to cut -- should I expect a single cutter to last long enough for that, or should I assume I'll need a couple of cutters?

Is there something obvious I'm missing? Thanks!