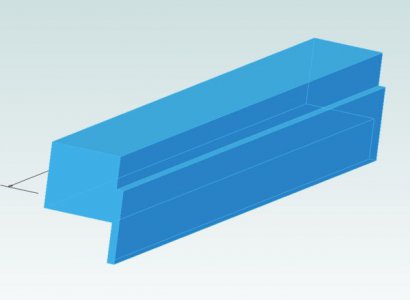

This is the frame for the mowing deck on a large walk behind mower I have (mow and deck have been removed, and it's upside down):

The chain is just on it because I used it to straighten that leg (it's 1" x 2" square tubing, likely 1/8" thick but I can't say for sure as I'd have to cut into it to find out).

Last year, I mounted a bagger on it. Here's how it's attached to the frame:

And the overall unit:

From use, the leg on each side as bent downwards about 1/4" (as in, using a straightedge, when it's flat on one end, there's about 1/4" gap between the other end of the leg and the straightedge).

The bagger unit and mount weight about 75 lbs and the vast majority of the time, the bags are empty or have very little in them, but sometimes they can have upto to about 150 lbs of stuff in them.

My question is, would a good way to reduce this bending be to weld a strip of angle iron to the bottom outside edge of that leg? I've got 1"x 1/8" and 1" x 1/4" angle iron that I could weld along that edge, with a cutout around that flat piece of steel with the slot in it. Or is there something else that would do a better job of stiffening those 2 legs?

I can also weld something to the outside of the legs (there's 2 brackets that I'd have to weld around), but I can't weld something bulky to the bottom of it (more than 1/2") as it would limit how high the mowing deck can be raised. The top of the legs have a number of mounting points on them, so I don't think anything useful can be done welding to the top, and welding to the inside of it would interfere with the mowing deck pulley cover.

The chain is just on it because I used it to straighten that leg (it's 1" x 2" square tubing, likely 1/8" thick but I can't say for sure as I'd have to cut into it to find out).

Last year, I mounted a bagger on it. Here's how it's attached to the frame:

And the overall unit:

From use, the leg on each side as bent downwards about 1/4" (as in, using a straightedge, when it's flat on one end, there's about 1/4" gap between the other end of the leg and the straightedge).

The bagger unit and mount weight about 75 lbs and the vast majority of the time, the bags are empty or have very little in them, but sometimes they can have upto to about 150 lbs of stuff in them.

My question is, would a good way to reduce this bending be to weld a strip of angle iron to the bottom outside edge of that leg? I've got 1"x 1/8" and 1" x 1/4" angle iron that I could weld along that edge, with a cutout around that flat piece of steel with the slot in it. Or is there something else that would do a better job of stiffening those 2 legs?

I can also weld something to the outside of the legs (there's 2 brackets that I'd have to weld around), but I can't weld something bulky to the bottom of it (more than 1/2") as it would limit how high the mowing deck can be raised. The top of the legs have a number of mounting points on them, so I don't think anything useful can be done welding to the top, and welding to the inside of it would interfere with the mowing deck pulley cover.