B

Bill Gruby

Forum Guest

Register Today

I very seldom venture into this domain. No I am not against guns. Here goes.

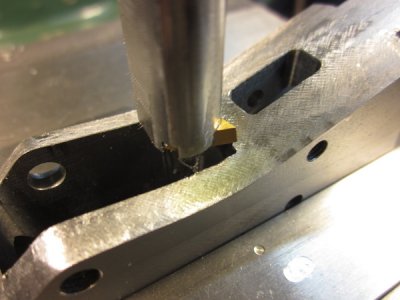

I was looking over a set of prints for the Sharps 1874. On the receiver there is a thru hole top to bottom. It measures 1.499" X .772" and travels for some 2.475" all the way thru. There is a radius on each corner traveling the length of the hole. The radius is a nominal .015". Without divulging any of your trade secrets, how do you get this type of radius.

"Billy G"

I was looking over a set of prints for the Sharps 1874. On the receiver there is a thru hole top to bottom. It measures 1.499" X .772" and travels for some 2.475" all the way thru. There is a radius on each corner traveling the length of the hole. The radius is a nominal .015". Without divulging any of your trade secrets, how do you get this type of radius.

"Billy G"