-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quick change tool post for G4000 Grizzly lathe

- Thread starter Frogdiver

- Start date

Little Machine Shop is a good source for OXA sized QCTP''s

littlemachineshop.com

littlemachineshop.com

Quick Change Tool Posts

Compare the many quick change tool posts for small lathes.

What matters is the lathe centerline distance to the top of the compound. There is some cross over between OXA and AXA, but if the distance is too short and you happen to purchased an AXA, there's the possibility that you won't be able to lower the tool holder enough to get it in centerline with the lathe.

An AXA will be more rigid if it fits, but on a mini lathe it might not be noticeable.

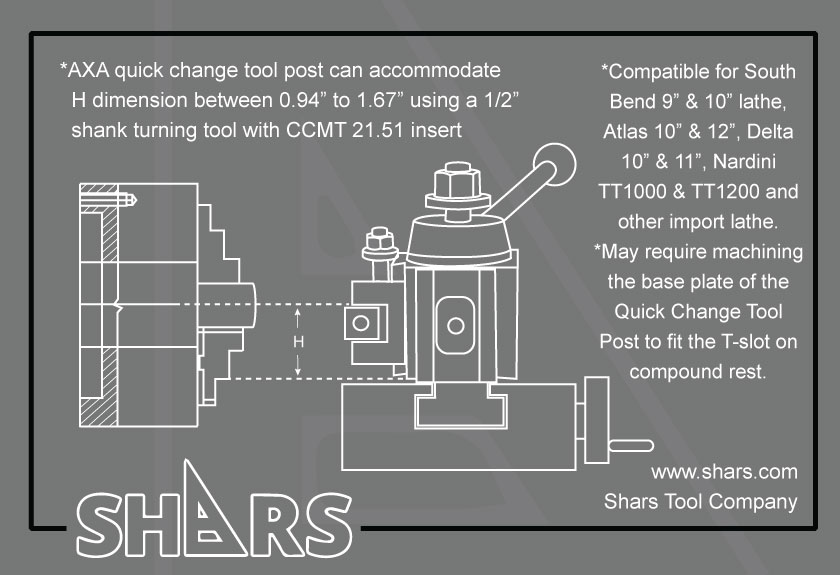

Here's a Shars image on determining the measurement for choosing the correct QCTP Size.

An AXA will be more rigid if it fits, but on a mini lathe it might not be noticeable.

Here's a Shars image on determining the measurement for choosing the correct QCTP Size.

- Joined

- Feb 13, 2017

- Messages

- 2,138

My small machine is a Grizzly G-1550. The only difference of note is the 1550 has imperial threads where the G-4000 has metric. The 1550 is from Taiwan, the 4000 is from mainland China. . . I use an "AXA" tool holder and have yet to have any difficulty getting center. Sorry, I don't have any measurements handy. But the AXA fits fine and tool holders are interchangable with a Craftsman 12" machine.

.

.

- Joined

- Feb 17, 2013

- Messages

- 4,406

I've owned two G4000s, and converted both to AXA QCTPs. First off, you need an adapter sleeve for the fixed stud atop the compound slide. Little Machine Shop sells one:

littlemachineshop.com

littlemachineshop.com

I've used both piston type and wedge type QCTPs. Both have worked well. Shars, CDCO, LMS, etc. sell the sets, as well as additional tool holders. I've not had trouble with any of them.

Possible modifications:

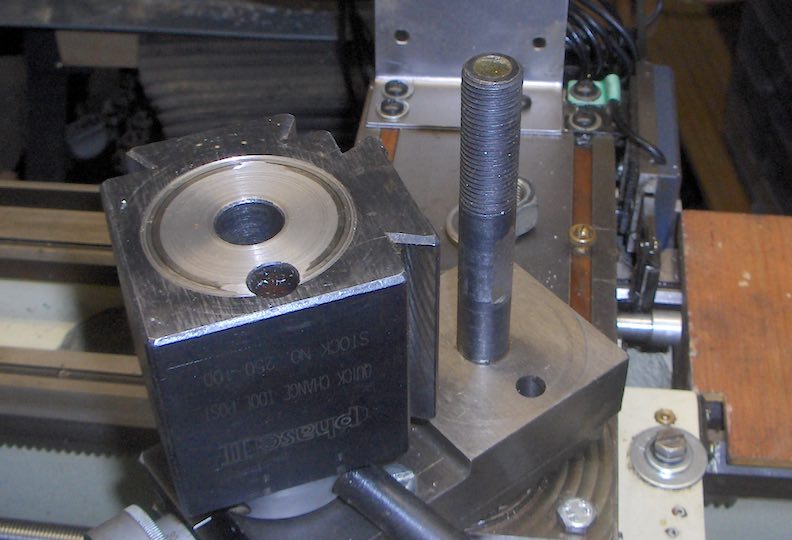

1. I noticed in at least one case that the stress of tightening the mounting nut tended to slightly bulge the center of the compound. When that happened, and the QCTP was mainly supported near the center, it became a bit too easy to rotat under load. I fixed this by chucking the QCTP in a 4-jaw and cutting away the central area about .010" deep. This shifted the holding force to the periphery of the QCTP head and held it firmly against unwanted rotation. PS - that's the LMS adapter stud on the compound.

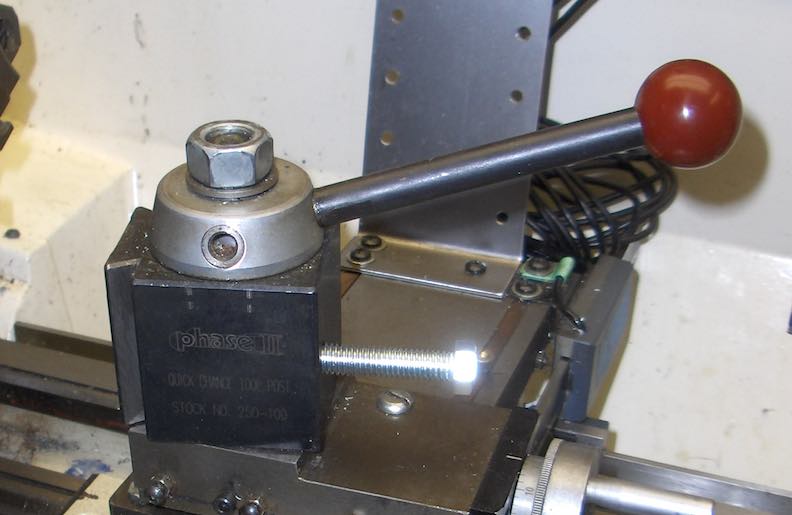

2. It seemed like the operating handle on the QCTP was not well located - always getting in the way of things. So I drilled/tapped three more holes at 90º intervals (using my mill). One of them turned out to be the best, so I left the handle there.

Stud, Quick Change Tool Post Mount, AXA for 9x20 Lathes 3712

QCTP Accessories 3712 Makes AXA QCTP a bolt-on accessory for 9x20 lathes; Threads over standard tool post stud; Outside thread is 9/16"-18; This tool ...

I've used both piston type and wedge type QCTPs. Both have worked well. Shars, CDCO, LMS, etc. sell the sets, as well as additional tool holders. I've not had trouble with any of them.

Possible modifications:

1. I noticed in at least one case that the stress of tightening the mounting nut tended to slightly bulge the center of the compound. When that happened, and the QCTP was mainly supported near the center, it became a bit too easy to rotat under load. I fixed this by chucking the QCTP in a 4-jaw and cutting away the central area about .010" deep. This shifted the holding force to the periphery of the QCTP head and held it firmly against unwanted rotation. PS - that's the LMS adapter stud on the compound.

2. It seemed like the operating handle on the QCTP was not well located - always getting in the way of things. So I drilled/tapped three more holes at 90º intervals (using my mill). One of them turned out to be the best, so I left the handle there.

Thank you, that looks like a good fit. Tool height was easy enough?I've owned two G4000s, and converted both to AXA QCTPs. First off, you need an adapter sleeve for the fixed stud atop the compound slide. Little Machine Shop sells one:

Stud, Quick Change Tool Post Mount, AXA for 9x20 Lathes 3712

QCTP Accessories 3712 Makes AXA QCTP a bolt-on accessory for 9x20 lathes; Threads over standard tool post stud; Outside thread is 9/16"-18; This tool ...littlemachineshop.com

I've used both piston type and wedge type QCTPs. Both have worked well. Shars, CDCO, LMS, etc. sell the sets, as well as additional tool holders. I've not had trouble with any of them.

Possible modifications:

1. I noticed in at least one case that the stress of tightening the mounting nut tended to slightly bulge the center of the compound. When that happened, and the QCTP was mainly supported near the center, it became a bit too easy to rotat under load. I fixed this by chucking the QCTP in a 4-jaw and cutting away the central area about .010" deep. This shifted the holding force to the periphery of the QCTP head and held it firmly against unwanted rotation. PS - that's the LMS adapter stud on the compound.

View attachment 344734

2. It seemed like the operating handle on the QCTP was not well located - always getting in the way of things. So I drilled/tapped three more holes at 90º intervals (using my mill). One of them turned out to be the best, so I left the handle there.

View attachment 344735