I made some rough plastic V blocks long ago to hold the tube hand guard of an AR15 while I drilled for a bipod stud. They have been sitting around the shop for ages so i decided to re-cut them a bit nicer.

First i cut them to the same dimensions on my mill and cut a center clearance slot. This critter looking thing came out as I slotted the center.

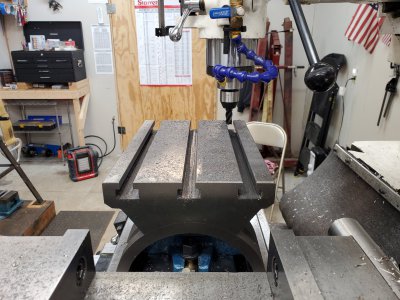

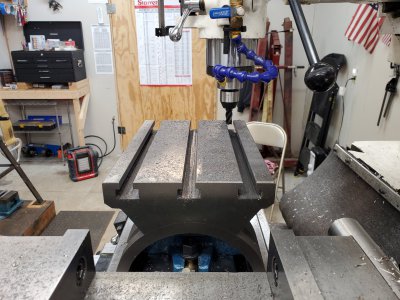

I decide to set them up on my adjustable angle plate for the angled part. My only easy option was to use a mi-tee bite and parallel to hold it snug and tapped the blocks down before the cut. The slots were wide enough on the bottom for regular 12mm stud t-nuts but not up top. I modified one nut to work and got the job done.

I flipped the block to keep the cut as identical as possible

After some quick measurements i realized if i open up the top of my slots to 0.540" i could use my 12mm T-nuts. Good thing i dialed it the table when i mounted it. Lol.

It's a great snowy day to be in the shop!

First i cut them to the same dimensions on my mill and cut a center clearance slot. This critter looking thing came out as I slotted the center.

I decide to set them up on my adjustable angle plate for the angled part. My only easy option was to use a mi-tee bite and parallel to hold it snug and tapped the blocks down before the cut. The slots were wide enough on the bottom for regular 12mm stud t-nuts but not up top. I modified one nut to work and got the job done.

I flipped the block to keep the cut as identical as possible

After some quick measurements i realized if i open up the top of my slots to 0.540" i could use my 12mm T-nuts. Good thing i dialed it the table when i mounted it. Lol.

It's a great snowy day to be in the shop!