- Joined

- May 20, 2014

- Messages

- 191

Just for fun, did an eBay search of 'bicycle speedometer'. OMG, over 4,000 items!

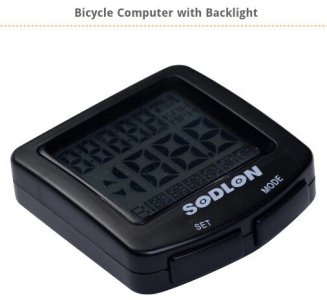

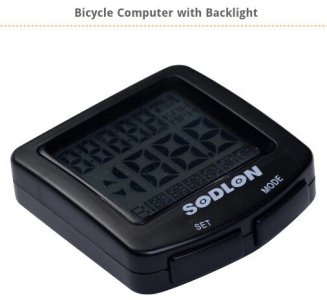

This one (about $3) caught my eye. Notice the large LCD number segments in the middle of the display, showing '188.8', where the speed would be displayed. If this thing could actually display as high as "199.9", might could work out as a tach by ignoring the decimal point. You program into these things the tire diameter or circumference, and choose MPH or KPH.

If you sit down and grind thru the math, realizing that you could attach more than one magnet, you may come up with a usable configuration...

This one (about $3) caught my eye. Notice the large LCD number segments in the middle of the display, showing '188.8', where the speed would be displayed. If this thing could actually display as high as "199.9", might could work out as a tach by ignoring the decimal point. You program into these things the tire diameter or circumference, and choose MPH or KPH.

If you sit down and grind thru the math, realizing that you could attach more than one magnet, you may come up with a usable configuration...