After studying the options, I installed a Mitutoyo Quill DRO kit on my PM935 mill. I acquired it on sale at Zoro for a decent price. The kit is for a Bridgeport or clone.

The install went reasonably well but did require a few tweaks to get it “right and tight”. I am sharing some of the details with some photos in case it may help someone who decides to go this route.

While the kit comes with instructions and a very good parts list, Adam’s (ABOM79) YouTube on mounting a kit on a Bridgeport was very helpful to familiarize one with the kit and how it mounts.

The kit came with all the hardware needed with the exception of two mounting screws needed for my PM935 install.

Here is a list of the things I did to make it fit and make the install better for my particular mill. This list is not intended to be all inclusive and one should confirm that the dimensions of your mill would require everything I did or perhaps something different.

Tweaks and insights:

I had to chase the small M3 threads in the mounting frame – the powder coat had choked the threads.

I had to countersink the holes on the back of sending unit mounting plate to accommodate the included #5 gun screws. Screws were too short as supplied to get proper thread engagement. I could have ordered proper length screws from McMaster but decided to simply use what I had and milled a step for them to sit in.

I milled off .060”of mounting bar to move the assembly closer to mill and to maximize the insertion of the mounting tube into the stop ring on the mill.

I bought two new mounting screws to attach the mounting bar (M4 x 12), one had to be ground slightly shorter to not interfere with the power feed mechanism. I did not leave the depth scale on the machine as called for in the instructions. I found this to not be needed for spacing nor add any functionality since the scale was covered if left in place.

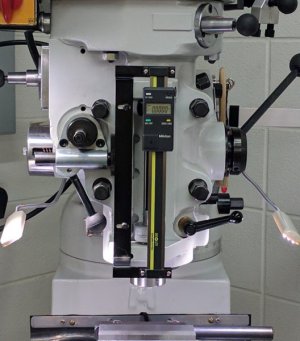

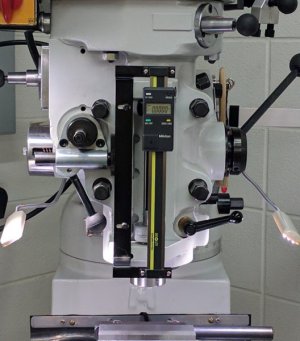

I shimmed the mounting tube to the mill’s stop ring joint to take up .010” of slack in the fit. This allowed the set screw to expand the mounting tube to a good firm fit and eliminate any wiggle in the joint. You can see the copper shim wrapped on the split tube in this photo. This shimming avoids the wiggle that ABOM79’s video shows. Thanks to Adam for making the YouTube since it catalyzed me shimming the tube/stop joint in the initial install and making it rock solid.

All in all a very good fit and function with just a little adapting and tuning. There's still plenty of room behind the Mitutoyo for the original depth stop function to be adjusted and work well. I can still put my depth stop clamp on the rod as well. Although many folks keep them removed anyway, the front fine feed crank/wheel also still fits without interference.

Hope this may help others if you decide to go this route. Here is the unit installed on my PM935TV.