- Joined

- Nov 8, 2011

- Messages

- 1,678

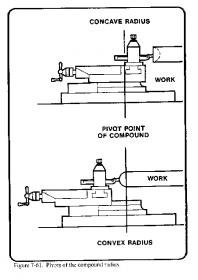

I've wanted one of these ever since I saw the first one way before I even got my lathe. I'm eventually building a bead roller and will need to make some custom made dies.

So last night I decided to make one with stuff I had on hand, I like recycling/re-using/re-purposing so I took a go/no go gauge from work for a machine gun mount socket that we had to destroy because it was out of tolerance. At first I was gonna use the gauge & the socket but realized it would be too high & limit the diameter of the ball/radius I could turn so I just used the gauge.

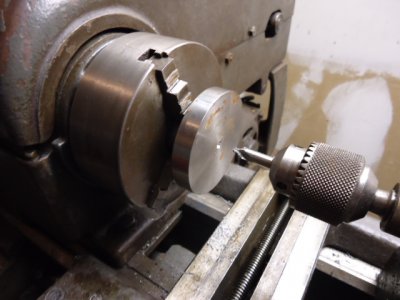

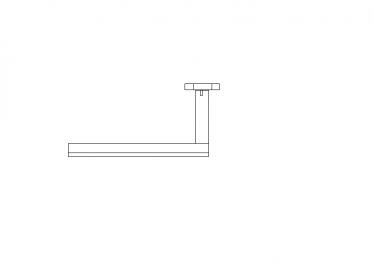

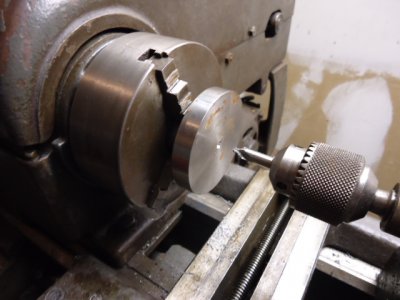

First I faced off the plug end that was cut at work to destroy it, then I turned it around and drilled a 1/2" hole in it to fit over the pin in my cross slide that's exposed after removing the compound cross slide. It turns nice and freely on the pin. Next op will be to mill a T slot across the small dia. end in the center to hold a tool holder I yet have to design but have an idea for which I seen on another design. The tool/cutter will be a double ended carbide insert .

I'm gonna drill and tap a few holes around the perimeter/edge of the larger dia. some straight in and some on an angle to thread in a handle.

So last night I decided to make one with stuff I had on hand, I like recycling/re-using/re-purposing so I took a go/no go gauge from work for a machine gun mount socket that we had to destroy because it was out of tolerance. At first I was gonna use the gauge & the socket but realized it would be too high & limit the diameter of the ball/radius I could turn so I just used the gauge.

First I faced off the plug end that was cut at work to destroy it, then I turned it around and drilled a 1/2" hole in it to fit over the pin in my cross slide that's exposed after removing the compound cross slide. It turns nice and freely on the pin. Next op will be to mill a T slot across the small dia. end in the center to hold a tool holder I yet have to design but have an idea for which I seen on another design. The tool/cutter will be a double ended carbide insert .

I'm gonna drill and tap a few holes around the perimeter/edge of the larger dia. some straight in and some on an angle to thread in a handle.