- Joined

- Dec 19, 2016

- Messages

- 211

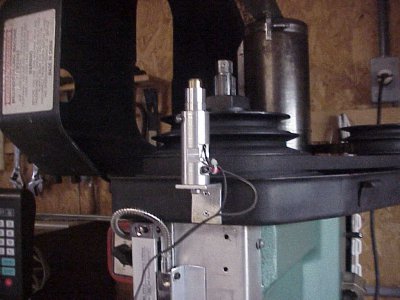

I have mounted the guts out of a laser pointer using a plug in power supply in lieu of battery.

This I mounted vertically on the front of the pully guard.

Then I mounted a stiff member onto the top of the round column.

The stationary member now has a .040 hole drilled in it that lines up with the laser beam when the head is in the proper position.

When the head is in the proper position the laser shines on the ceiling.

Now i can realign my mill head most effectively in short order.

This I mounted vertically on the front of the pully guard.

Then I mounted a stiff member onto the top of the round column.

The stationary member now has a .040 hole drilled in it that lines up with the laser beam when the head is in the proper position.

When the head is in the proper position the laser shines on the ceiling.

Now i can realign my mill head most effectively in short order.