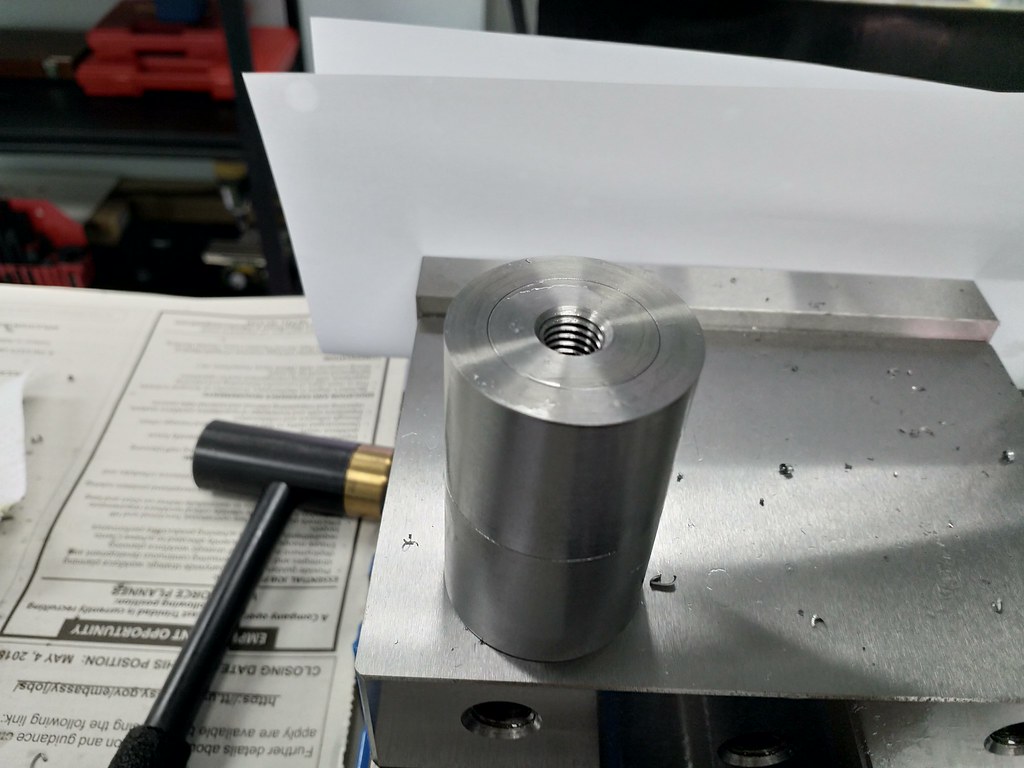

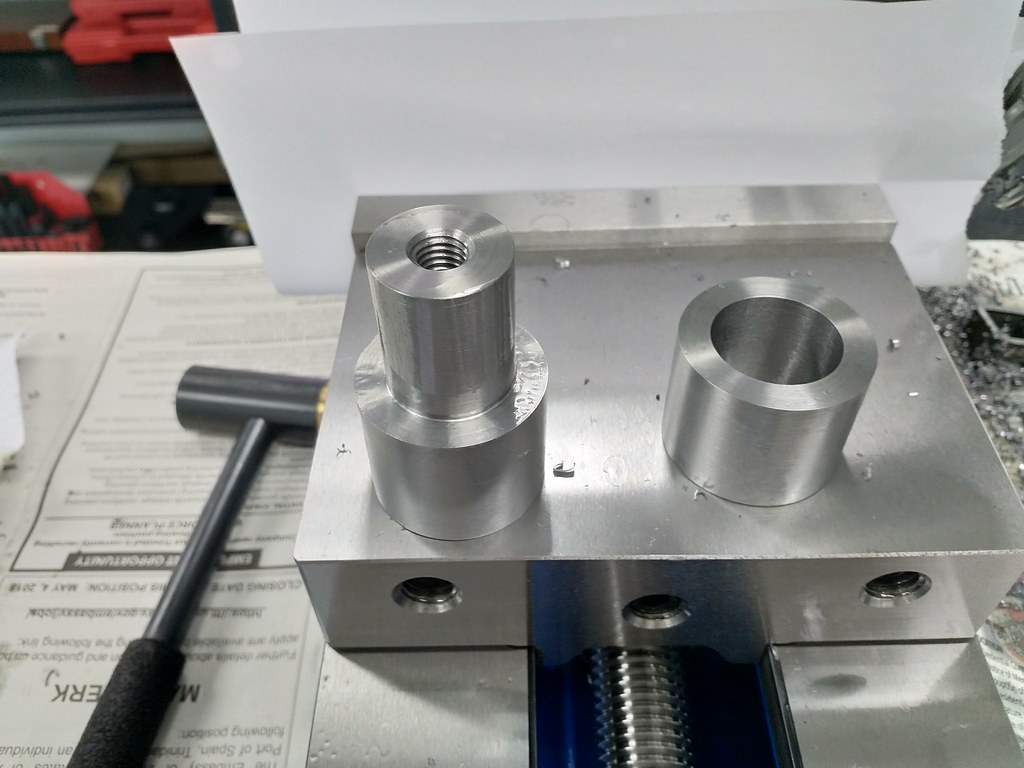

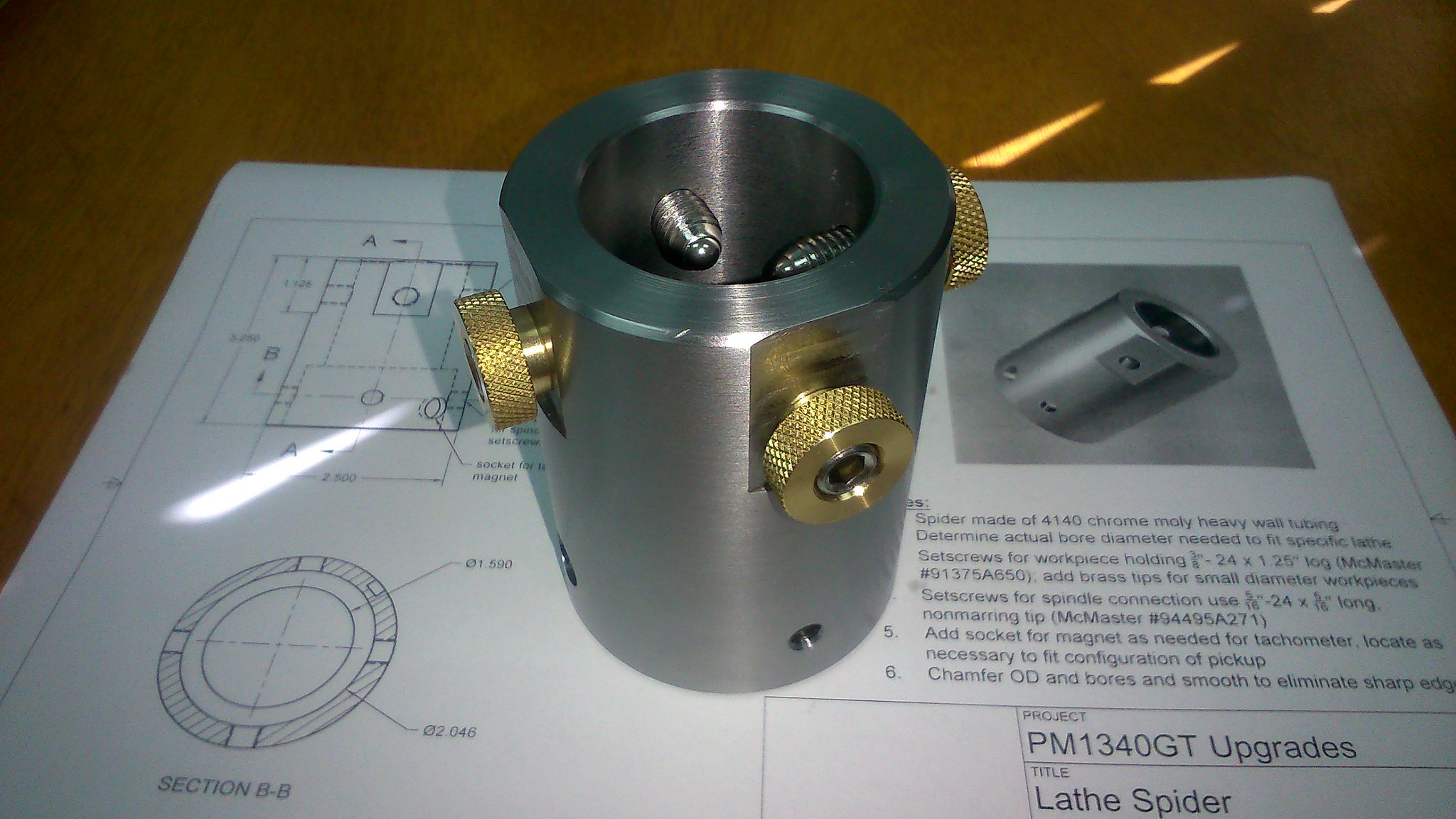

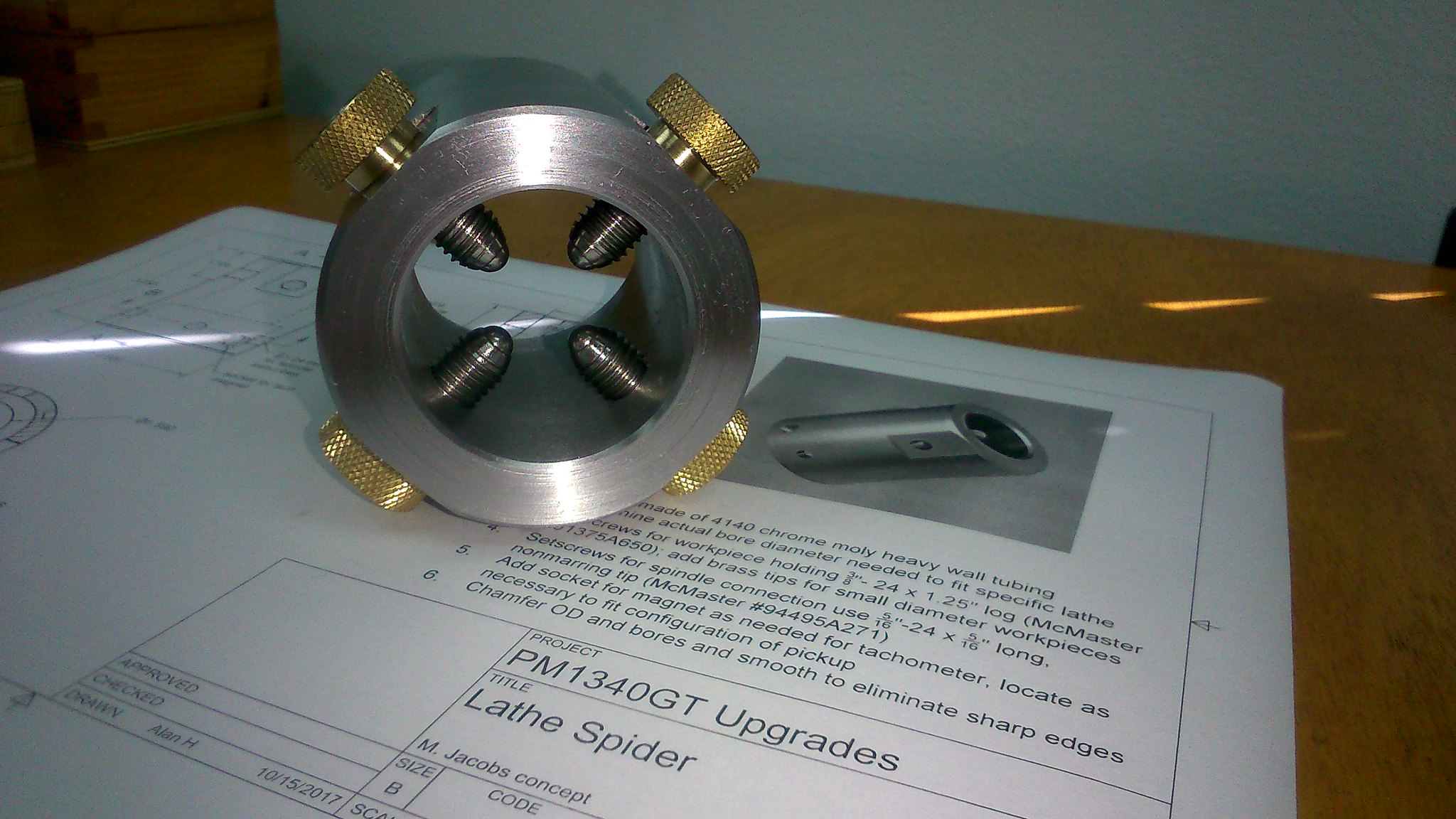

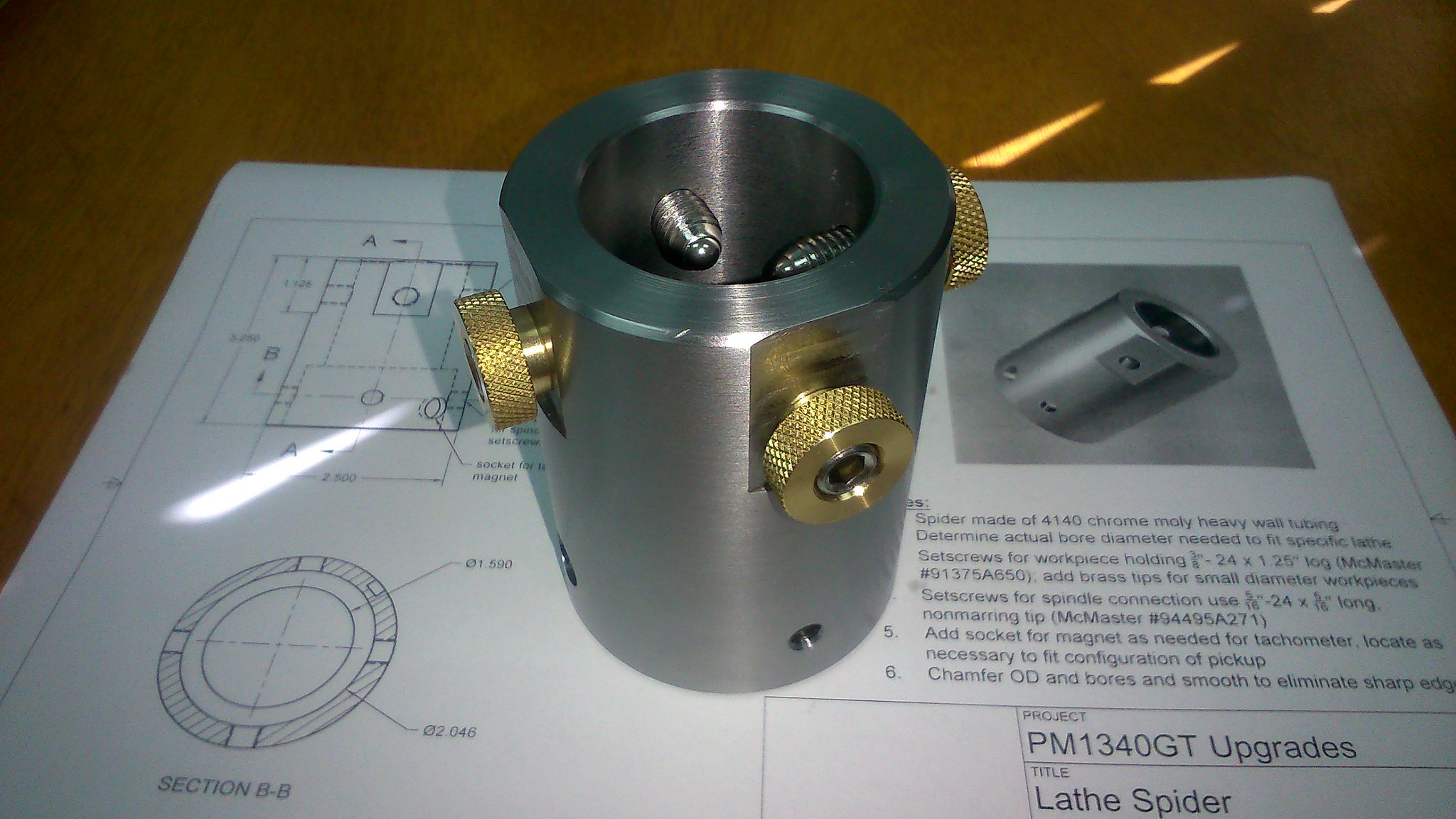

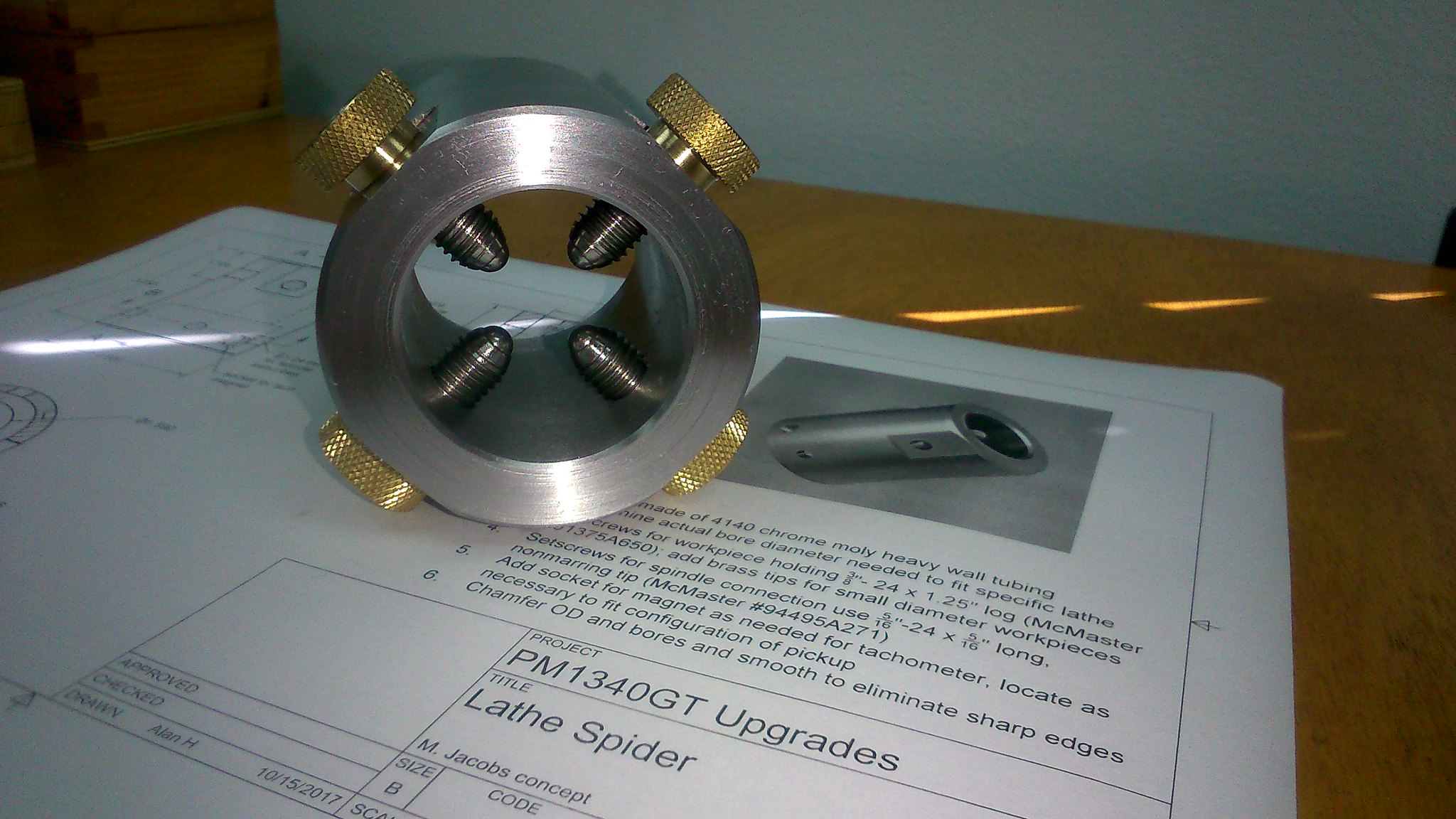

Finished up my Spider for the lathe using Allan's drawings. Thanks for sharing these Allan!

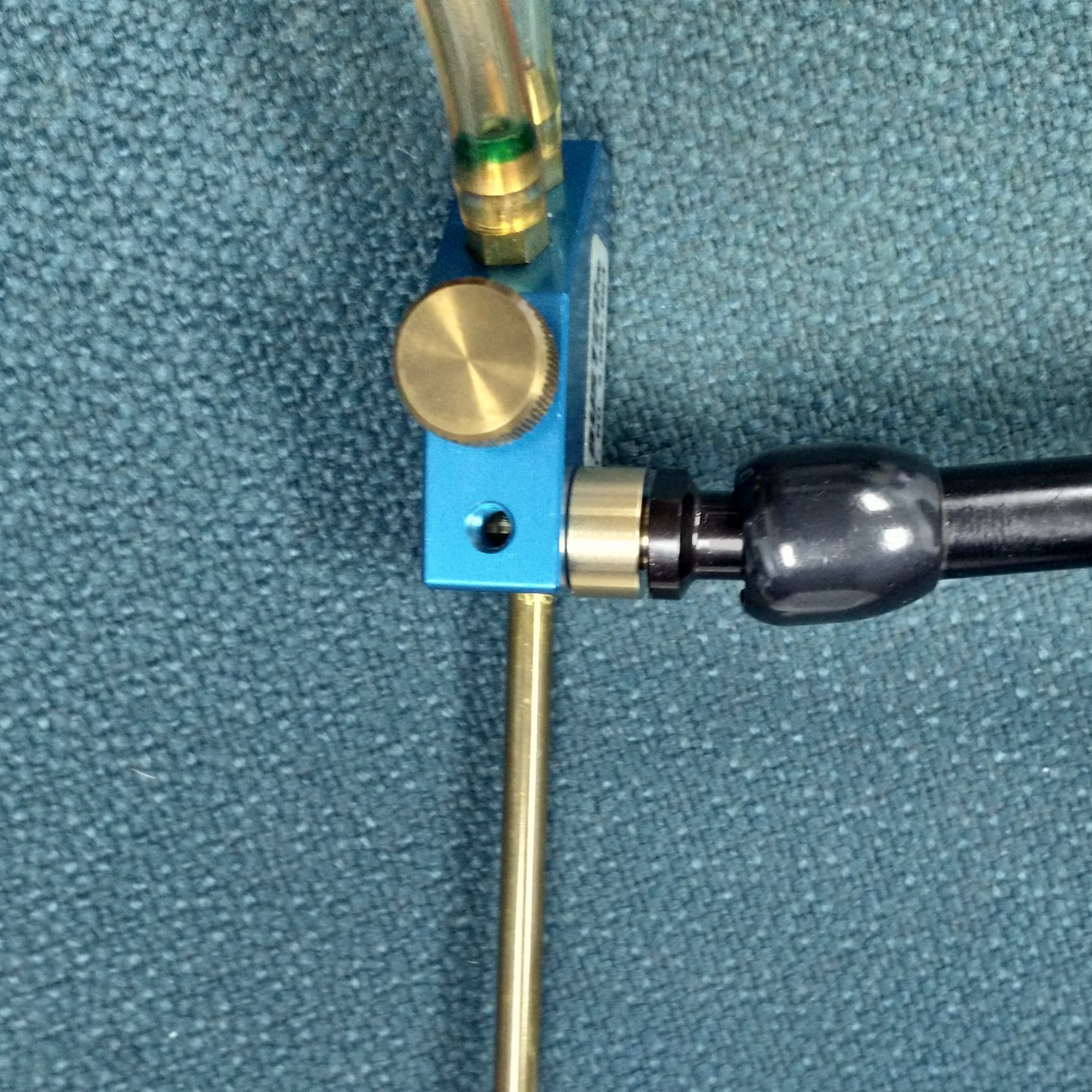

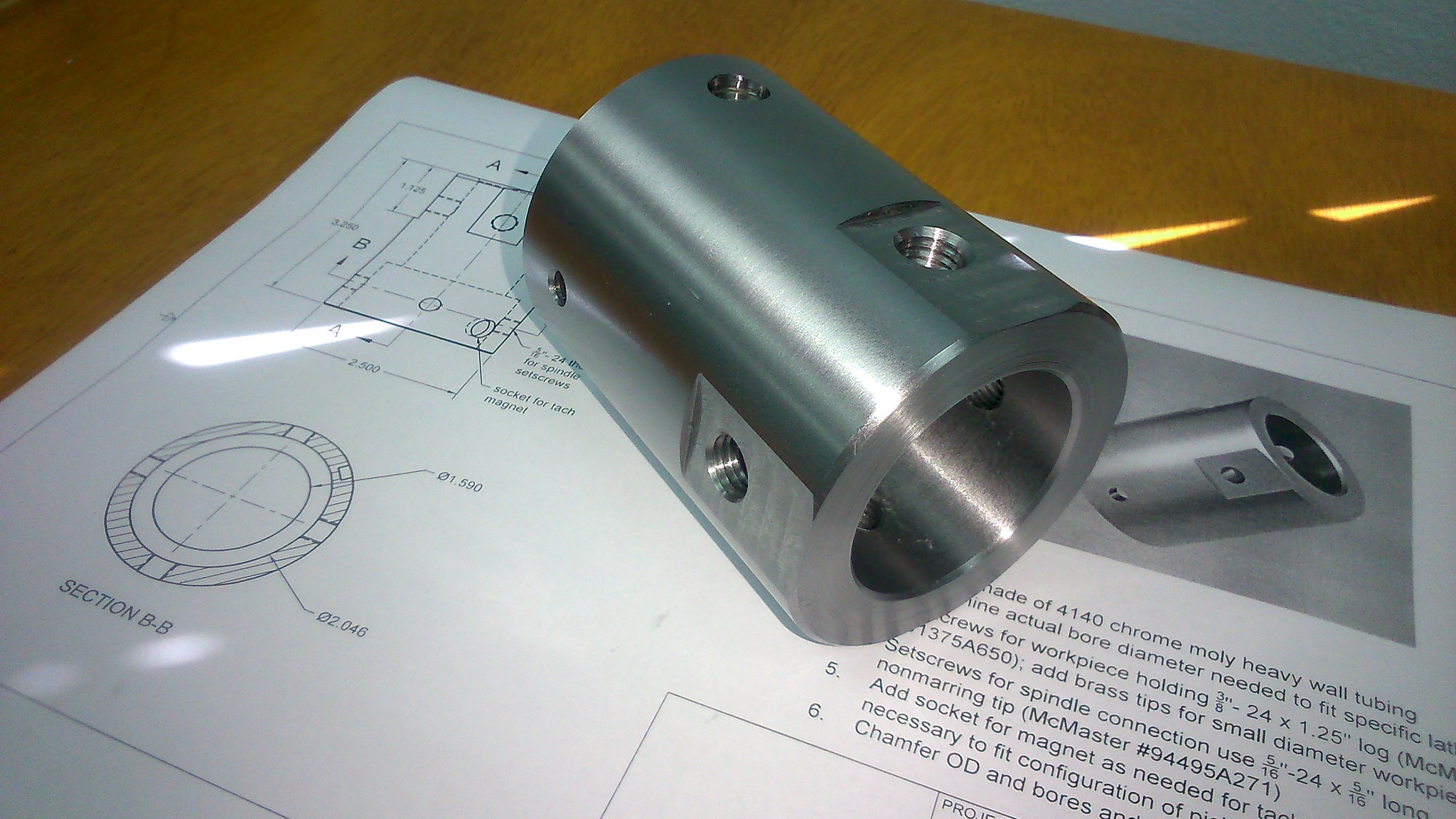

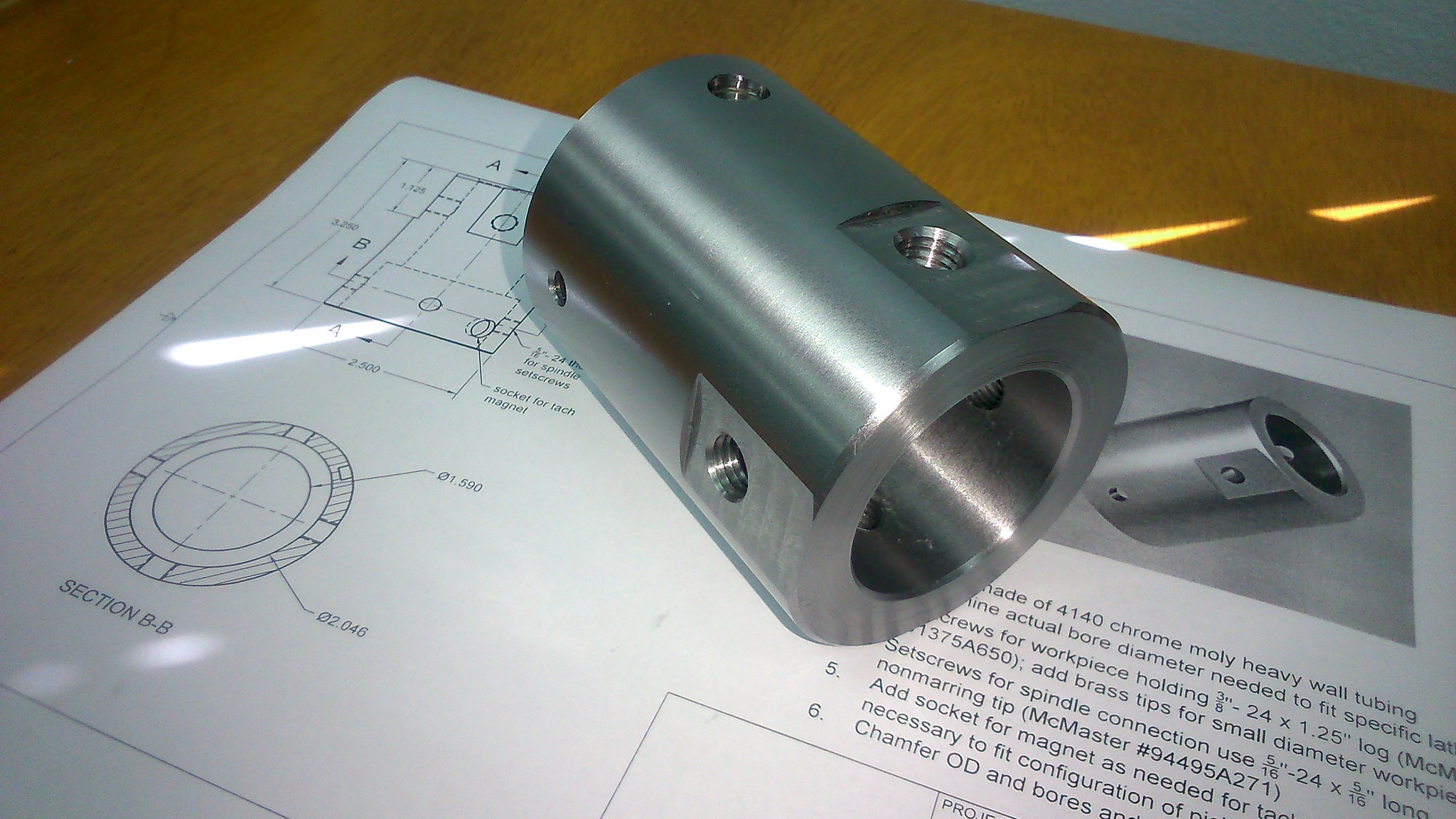

I did use metric hardware instead of what was called out in the drawing. For the adjusting set screws I used M10 with spring loaded ball bearings on the tips. M6 brass tipped set screws were used for mounting to the lathe's spindle. There is a 10mm pocket for the tachometer's magnet. A 3mm hole was drilled thorough the center of this pocket to aid in the removal of the magnet if needed.

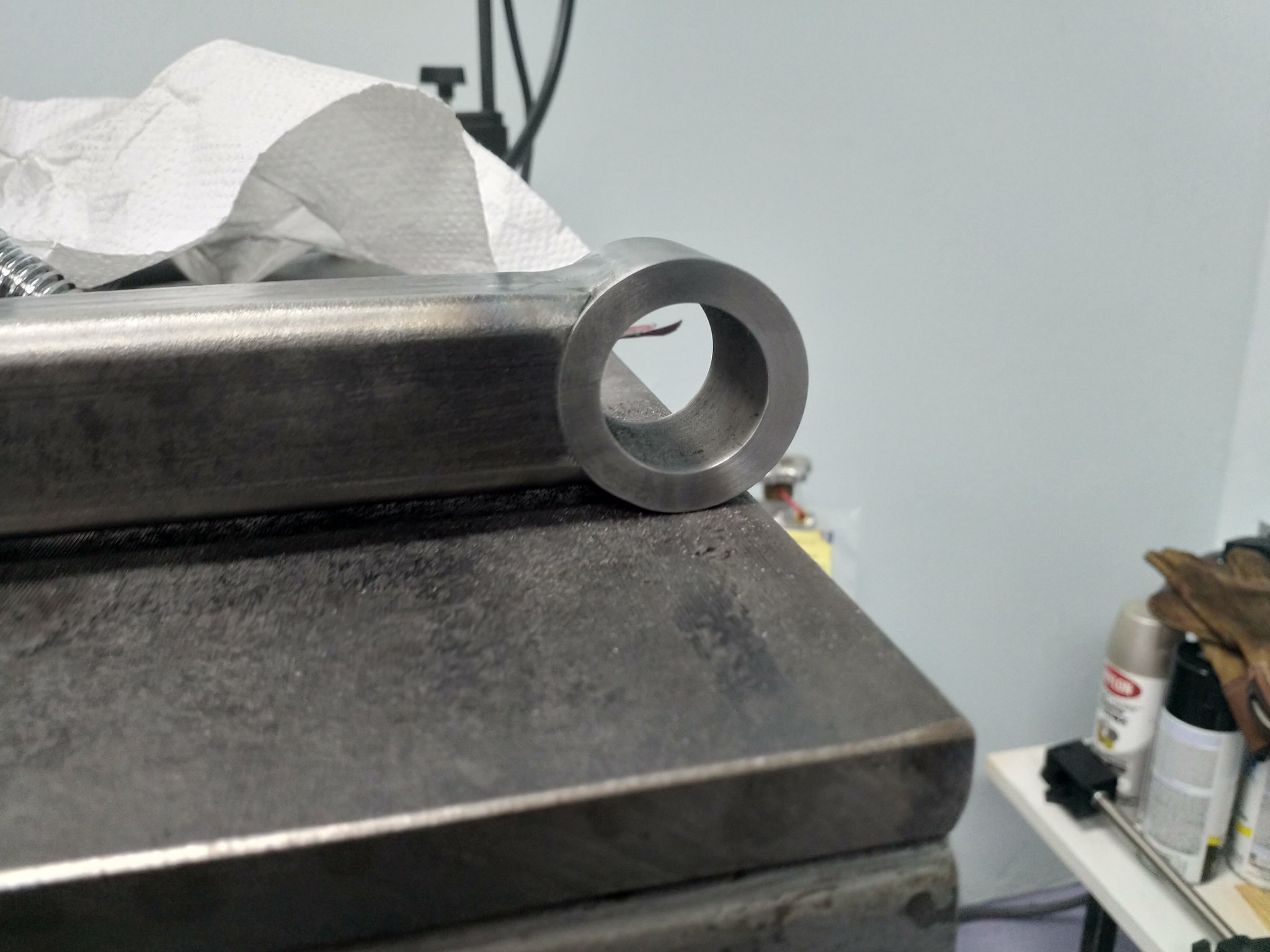

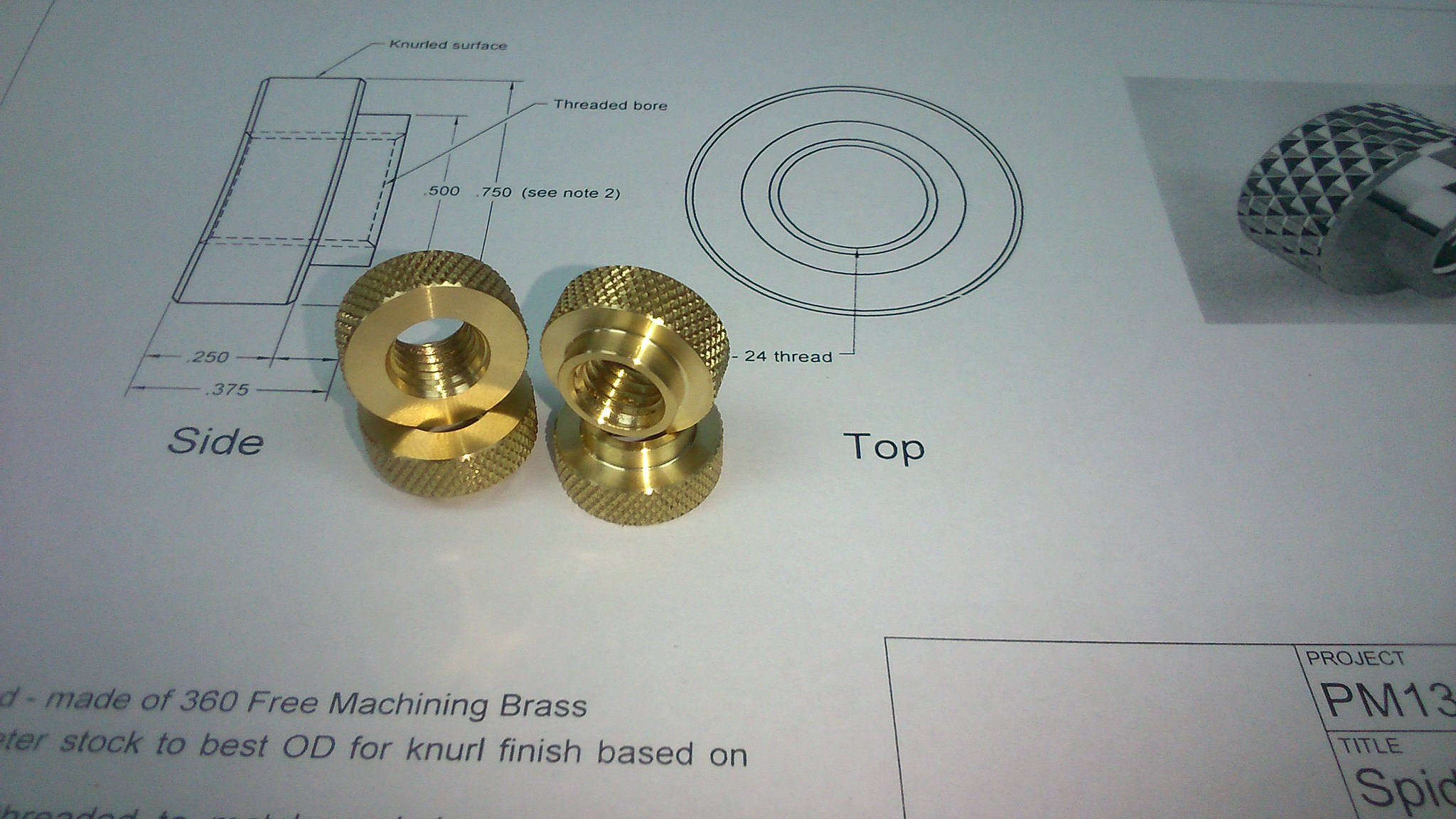

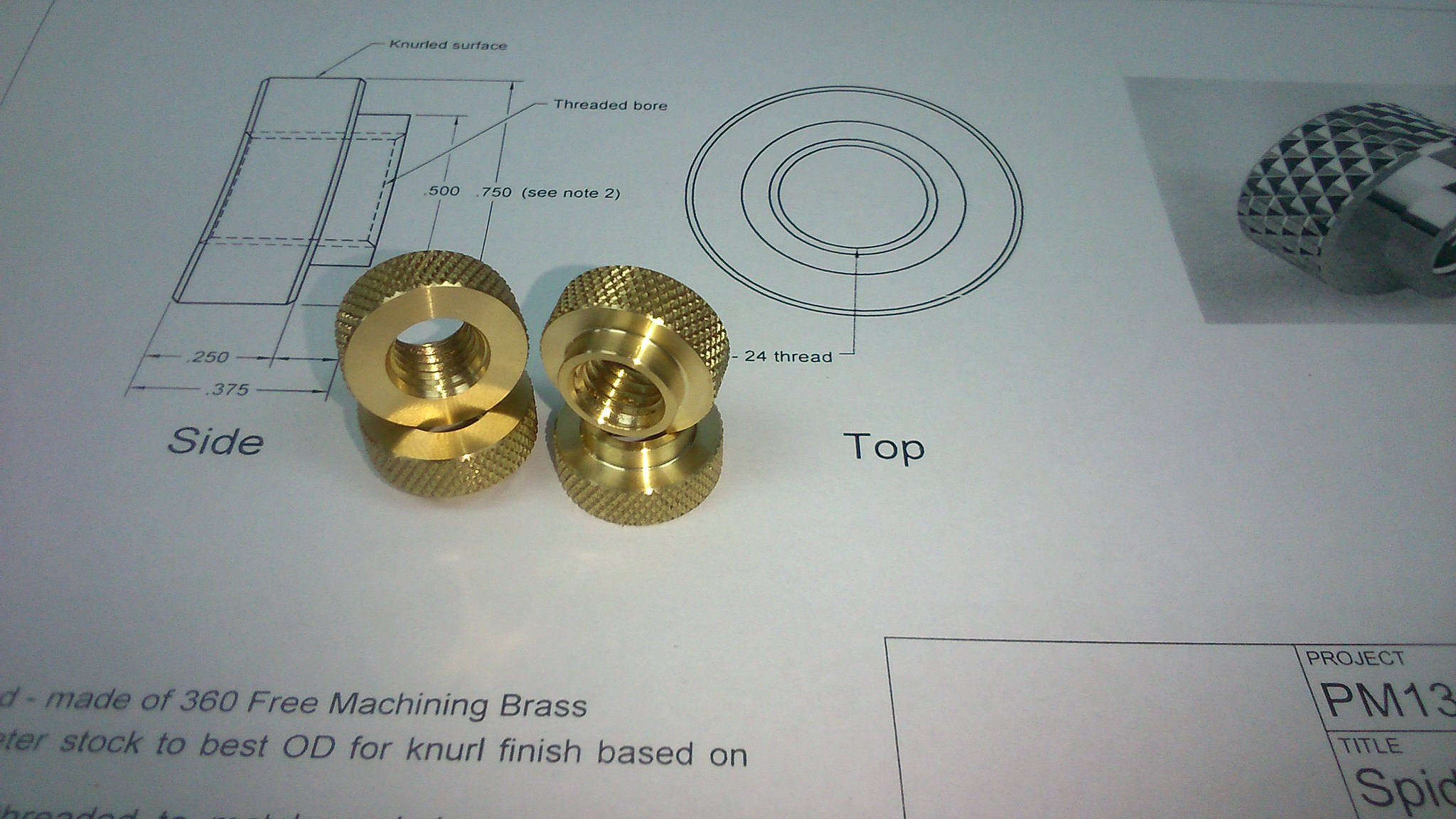

Thumb nuts are made from 360 brass and the spider body from 2.5" 4140 tubing.

Chevy

I did use metric hardware instead of what was called out in the drawing. For the adjusting set screws I used M10 with spring loaded ball bearings on the tips. M6 brass tipped set screws were used for mounting to the lathe's spindle. There is a 10mm pocket for the tachometer's magnet. A 3mm hole was drilled thorough the center of this pocket to aid in the removal of the magnet if needed.

Thumb nuts are made from 360 brass and the spider body from 2.5" 4140 tubing.

Chevy