I recently acquired this Clausing 4804, and I believe the vintage is 1955-ish, Serial Number: 17321.

Im only in it for $250. I was told that the lathe is functional but has a couple of issues, the previous owner told me that the cross slide threads were worn, and that the clutch was going out, he also told me that it could use new chuck jaws.

am trying to figure out if this lathe is worth putting some money into. It's for home shop use.

I'll address the issues one by one, some of them are hard to describe so I made a video that I will link. I will outline specific times of the video next to the problem descriptions below.

First issue: Cross Slide threads, as I stated before the previous owner spoke about replacing the cross slide threads. There seems to be some play in the crank. If I tighten the collar (with the indication marks), the slide firms up with much less play. Are the threads bad or does the collar just need adjusted? - For video fast forward to 1:20 min

Grinding Gear, if you fast forward to 7:10 I start the lathe and run it through the different speed settings. I run the motor through its RPM range, and I happen to have the threading setting activated and positioned on the 5th gear from the left side of the selection box. During the test, I pushed the sliding gear handle on the back of the lathe to the “in” position and got a terrible grinding sound (Video: 9:30). After inspecting all gears I found the problem (Video 10:02).

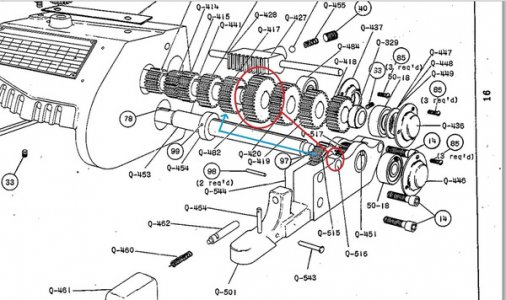

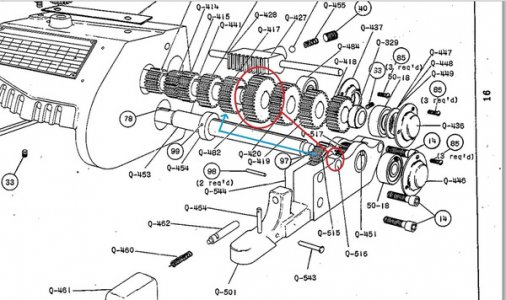

There is a gear that engages with the threaded rod (it is not a gear you can select with the handle). It is a large diameter gear located in the center of the gear tree (circled in red below). It is directly to the right of the gear I had randomly selected. When the fifth gear is selected (blue arrow), the bracket of the selector (circled in red) collides with this gear circled in red (Part Q-482, manual lists it as a tumbler shaft). I think the gear was grinding the entire time I was testing it, I think I didn’t notice it because the hi-torque and low speed of the other settings made it hard to realize something was grinding. The sliding gear on the rear of the lathe does not change anything in threading gear box from what I can tell, so it must have been grinding the hole time. Why on earth is this happening? I just don’t get it.

All in all, I am trying to figure out if this lathe is worth the investment in time and tooling. Beyond that, I am trying to figure out if it needs any replacement parts (like the cross-slide threads maybe?), threading gear? ect.

The chuck had about 6 thou run-out when I clamp down a drill bit in the chuck. I tested the ways by locking down the saddle until I got a little resistance and then ran the saddle front to back. It does give me more resistance in the middle and rear of the ways but it can make it all the way without binding hard. I know this means the ways are worn, but how worn? Does this need to be addressed?

Any help appreciated!

Im only in it for $250. I was told that the lathe is functional but has a couple of issues, the previous owner told me that the cross slide threads were worn, and that the clutch was going out, he also told me that it could use new chuck jaws.

am trying to figure out if this lathe is worth putting some money into. It's for home shop use.

I'll address the issues one by one, some of them are hard to describe so I made a video that I will link. I will outline specific times of the video next to the problem descriptions below.

First issue: Cross Slide threads, as I stated before the previous owner spoke about replacing the cross slide threads. There seems to be some play in the crank. If I tighten the collar (with the indication marks), the slide firms up with much less play. Are the threads bad or does the collar just need adjusted? - For video fast forward to 1:20 min

Grinding Gear, if you fast forward to 7:10 I start the lathe and run it through the different speed settings. I run the motor through its RPM range, and I happen to have the threading setting activated and positioned on the 5th gear from the left side of the selection box. During the test, I pushed the sliding gear handle on the back of the lathe to the “in” position and got a terrible grinding sound (Video: 9:30). After inspecting all gears I found the problem (Video 10:02).

There is a gear that engages with the threaded rod (it is not a gear you can select with the handle). It is a large diameter gear located in the center of the gear tree (circled in red below). It is directly to the right of the gear I had randomly selected. When the fifth gear is selected (blue arrow), the bracket of the selector (circled in red) collides with this gear circled in red (Part Q-482, manual lists it as a tumbler shaft). I think the gear was grinding the entire time I was testing it, I think I didn’t notice it because the hi-torque and low speed of the other settings made it hard to realize something was grinding. The sliding gear on the rear of the lathe does not change anything in threading gear box from what I can tell, so it must have been grinding the hole time. Why on earth is this happening? I just don’t get it.

All in all, I am trying to figure out if this lathe is worth the investment in time and tooling. Beyond that, I am trying to figure out if it needs any replacement parts (like the cross-slide threads maybe?), threading gear? ect.

The chuck had about 6 thou run-out when I clamp down a drill bit in the chuck. I tested the ways by locking down the saddle until I got a little resistance and then ran the saddle front to back. It does give me more resistance in the middle and rear of the ways but it can make it all the way without binding hard. I know this means the ways are worn, but how worn? Does this need to be addressed?

Any help appreciated!

Last edited: