- Joined

- Sep 22, 2020

- Messages

- 8

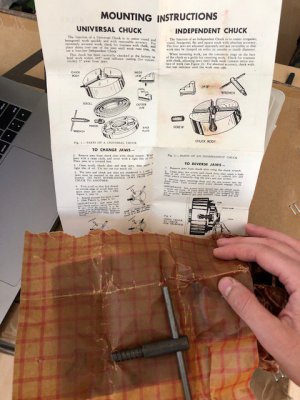

Hey there, first post here! I kind of just inherited a NOS Atlas 10100 lathe and Id like to get it in working order.

I know I need a motor for it(i believe 1/3 HP is needed), but am wondering what else is missing.

-Will any old 1/3HP motor work? I have the belt already new in packaging.

-I know im missing some other parts for it, but can anyone help me figure out what else is needed to get this going?

Thanks all!!

I know I need a motor for it(i believe 1/3 HP is needed), but am wondering what else is missing.

-Will any old 1/3HP motor work? I have the belt already new in packaging.

-I know im missing some other parts for it, but can anyone help me figure out what else is needed to get this going?

Thanks all!!