- Joined

- Mar 26, 2018

- Messages

- 8,407

I bought this for $10.

Set it in the side yard until this morning.

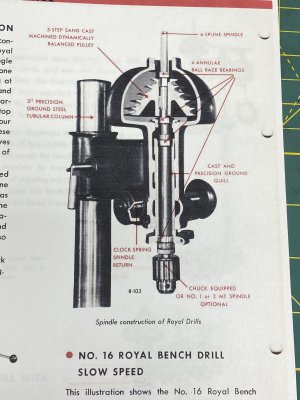

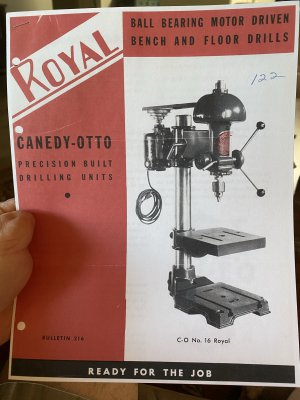

I found the sale catalog for this beautiful drill press on vintage machinery.org.

I’m not into blinging out old machines but I may strip the paint, prime and shoot with new paint.

It has a five sheave pulley, two speed groups. 460 to 5,200 and 385 to 3,110. I guess I get to make a pulley?

Bright metal and new bearings are in order. Four bearings in the spindle housing. 1/3 hp motor? That will change.

Stay tuned, rebuilding old machine tools got me started in this hobby.

Do I need a drill press? Hell no. I have two already. One is a new Jet 20”, floor and the other is an old precision small bench.

Just have to do it!

Mid 30’s? Me thinks.

Set it in the side yard until this morning.

I found the sale catalog for this beautiful drill press on vintage machinery.org.

I’m not into blinging out old machines but I may strip the paint, prime and shoot with new paint.

It has a five sheave pulley, two speed groups. 460 to 5,200 and 385 to 3,110. I guess I get to make a pulley?

Bright metal and new bearings are in order. Four bearings in the spindle housing. 1/3 hp motor? That will change.

Stay tuned, rebuilding old machine tools got me started in this hobby.

Do I need a drill press? Hell no. I have two already. One is a new Jet 20”, floor and the other is an old precision small bench.

Just have to do it!

Mid 30’s? Me thinks.

Attachments

-

E4870192-95EB-4424-B7F7-82CB597FECB5.jpeg1.2 MB · Views: 42

E4870192-95EB-4424-B7F7-82CB597FECB5.jpeg1.2 MB · Views: 42 -

9EC40DB0-3B68-461B-8F4F-0FDD32B9FBCE.jpeg807.6 KB · Views: 38

9EC40DB0-3B68-461B-8F4F-0FDD32B9FBCE.jpeg807.6 KB · Views: 38 -

934BC9AE-0997-413C-B1A1-5D7467F5883A.jpeg922.5 KB · Views: 39

934BC9AE-0997-413C-B1A1-5D7467F5883A.jpeg922.5 KB · Views: 39 -

671C015F-903A-45D9-9A53-5F38C4E22162.jpeg964.3 KB · Views: 37

671C015F-903A-45D9-9A53-5F38C4E22162.jpeg964.3 KB · Views: 37 -

D2745117-3D18-4947-96C5-ACEC9A61851E.jpeg903.8 KB · Views: 33

D2745117-3D18-4947-96C5-ACEC9A61851E.jpeg903.8 KB · Views: 33 -

90A8AA51-466B-4CC3-BA59-E242BD61FA9B.jpeg1.4 MB · Views: 31

90A8AA51-466B-4CC3-BA59-E242BD61FA9B.jpeg1.4 MB · Views: 31 -

4BC48665-D4D5-464E-AB8B-6F7201FABC1F.jpeg1 MB · Views: 30

4BC48665-D4D5-464E-AB8B-6F7201FABC1F.jpeg1 MB · Views: 30 -

A15ECFB8-8750-4A8C-98A8-1A49DB2DF4BF.jpeg1 MB · Views: 30

A15ECFB8-8750-4A8C-98A8-1A49DB2DF4BF.jpeg1 MB · Views: 30 -

D3414056-2847-489E-A290-67968023A4A3.jpeg1.1 MB · Views: 41

D3414056-2847-489E-A290-67968023A4A3.jpeg1.1 MB · Views: 41

Last edited: