- Joined

- Mar 25, 2018

- Messages

- 131

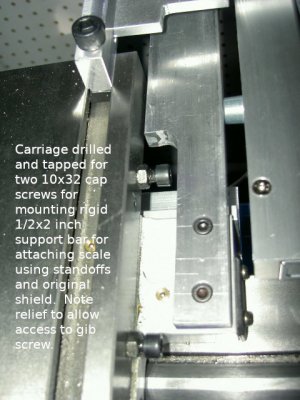

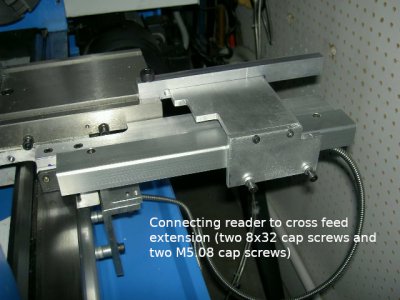

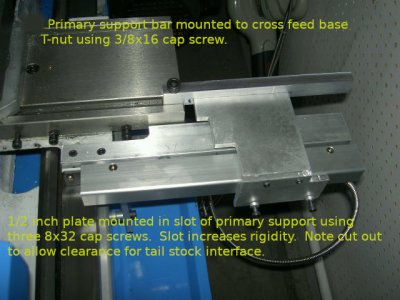

When my PM1127VF-LB was delivered the DRO was already installed. I found that the way it was installed placed the cross feed reader component between the tail stock and the carriage. That troubled me for two reasons. It placed the reader in a position that, although a “stop screw” was in place to reduce the liklihood of it happening, it could be damaged if the carriage and tail stock collided. It also meant that space I might need to position the tail stock as close as possible to the chuck was reduced by a couple of inches. In search of a solution I found a YouTube post

featuring “MrPragmaticLee” (he has some real good ideas) that inspired me to move the cross feed reader component of the DRO to the rear of the ways. I wanted something with greater rigidity than the one in the video so I gathered up some 6061 aluminum stock and went to work. These images reveal the “almost finished” product - I still have to replace one of the gib adjusting cap screws with a hex head (it’s impossible to access that stock cap screw as things are currently installed). This conversion required a few tasks to be performed using the mill but, in a pinch and with some patience, a metal cutting band saw or even a hacksaw will get the job done.