M

Mister Ed

Forum Guest

Register Today

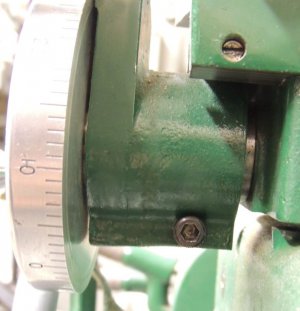

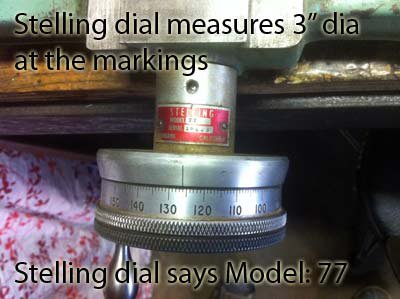

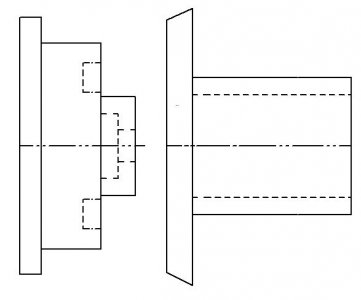

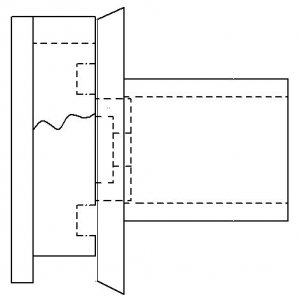

Ok, after life getting in the way for the last 6 months I am finally back on the kick to redo the cross feed dials on the 210. Well there certainly is a lot of 'buzz' on this subject since MrPete's video series. However, I really want to go with 200 graduations and a large (3") dial ... without loosing working capacity. So, really I want to recreate the Stelling set up, or very similar. Most of the external dimensions of the Stelling are available (I think even reposted here someplace). But I have a few questions if there is anyone that is familiar with them.

- Did stelling dials use the original cross slide screw?

- What did the internals look like? Bushings, thrust bearings, ets?

- Was the graduated ring adjustable (zero-able)? Or was it solid with the rest of the movable dial?