- Joined

- Apr 9, 2023

- Messages

- 38

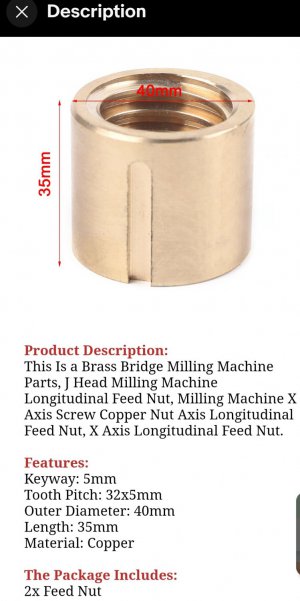

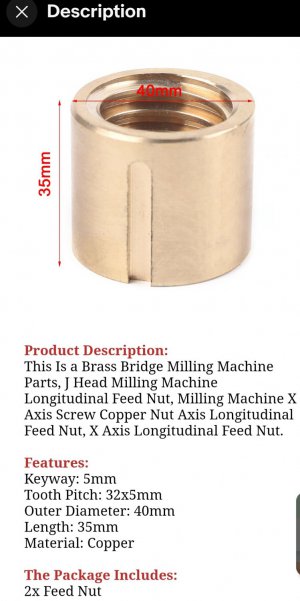

Hi all, i ordered this for my series 1 vari speed mill 2HP version and it didnt work for the X axis. I have another coming for the Y from a different company. I am hoping this one works because the Y axis is the one with 30 thou saddle play. The x axis nuts are gravy, i just wanted to have extras but these extras become tight as soon as nearly all the threads are engaged on the nuts. I feel like this means the pitch on the nuts are off. They dont work on either end, they stop at the same location yet the OEM nuts work fine.

Thoughts?? The item says for bridgeport....

Thoughts?? The item says for bridgeport....