- Joined

- Nov 15, 2017

- Messages

- 15

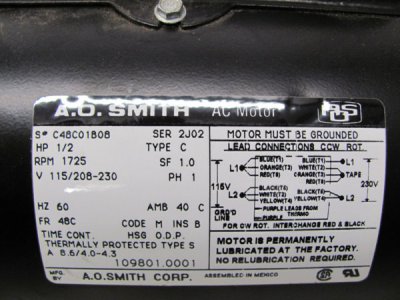

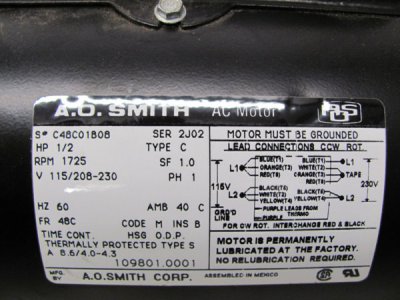

About a year ago, I purchased a used and somewhat neglected Harbor Freight 44142 3 in 1 machine. After setting it up and using it for a few months, I noticed that the lathe motor would get hot to the touch after about 10 minutes of use, and extremely hot after about 15 minutes of use. I removed and disassembled the motor to find no obvious problems. I had read about these motors having capacitor problems, so while it was out, I replaced both the start and the run capacitor. Once the motor was reassembled, and the capacitors were installed (on fabricated brackets since the replacements were somewhat larger than the originals), I wired it up to the machine with the motor not installed and sitting next to the machine. I wanted to run the motor uninstalled, and under no load to see if the motor overheated again, which it did. I determined that there was a likely issue with the windings, and it was not able to be repaired. I had no interest in spending what I considered too much money in a direct replacement motor from Grizzly(the Grizzly G9729 is almost an exact copy), so I went looking for a more common size replacement motor. Measuring the dimensions of the failed motor, I came to the conclusion that the closest motor size on the NEMA reference chart was the 48C frame size. I was fortunate enough to source a new surplus motor very inexpensively. Although, the replacement motor that I bought has a larger face mount bolt circle than the standard 48C frame motor would have. As a result, I had to make an aluminum adaptor plate to mount onto the motor so that the motor would fit the original motor mounting bracket. A standard 48C frame motor would not need such a plate fabricated. Rather, all one would have to do would be to elongate the existing bolt circle holes on the original mounting bracket slightly to accommodate the replacement motor. The original motor pulley measures .630" I.D. just .005" larger than .625", or 5/8". The replacement motor has a 5/8" shaft. My solution was to install a 3/16" keyway to replace the original metric key that is too large to fit the 3/16" replacement motor keyway, and shim the .005" clearance between the shaft and pulley with some aluminum from a soda can. The wiring was a straightforward task, although, I used shielded flexible conduit between the motor, and machine. See attached photos.

Last edited: