I inherited dads lathe and am getting it running again. It hasn't been run in about 30 years. It's a Craftsman 101.07403 Serial Number 18639. It has Timken bearings and is a change gear machine.. The spindle is tight with no appreciable wear, so no plans to remove it at this time.

So far, I've managed to get all the parts to work Except the half-nuts are stuck open. The plan is to pull the carriage and clean/lube the half-nut assembly. I've managed to get everything else working so far with general cleaning and lubrication.

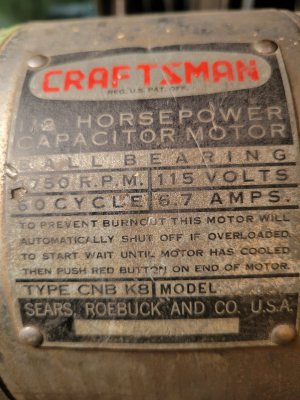

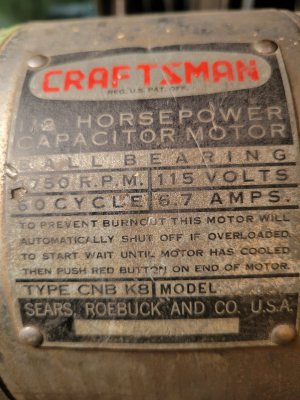

I was about 10 or so I think when this lathe was delivered. (That would've been about 1965). I do remember it was delivered strapped to the back of an Army surplus jeep! I have no idea what the cost was. As long as I can remember, it has been this shade of green, though it's starting to chip off and the original blue/grey is underneath. I have quite a few accessories including the original Atlas branded 6" 3 jaw chuck and Craftsman 1/2 HP motor

Enough talk.... How about some pictures!

So far, I've managed to get all the parts to work Except the half-nuts are stuck open. The plan is to pull the carriage and clean/lube the half-nut assembly. I've managed to get everything else working so far with general cleaning and lubrication.

I was about 10 or so I think when this lathe was delivered. (That would've been about 1965). I do remember it was delivered strapped to the back of an Army surplus jeep! I have no idea what the cost was. As long as I can remember, it has been this shade of green, though it's starting to chip off and the original blue/grey is underneath. I have quite a few accessories including the original Atlas branded 6" 3 jaw chuck and Craftsman 1/2 HP motor

Enough talk.... How about some pictures!

Last edited: