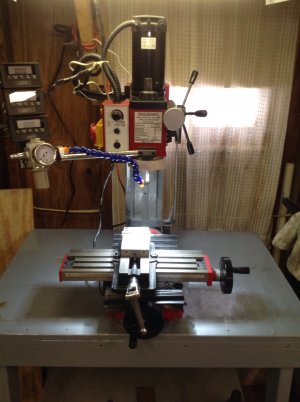

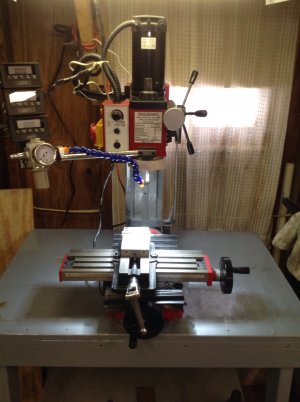

Ok, so here's a couple pictures of something new and shiny for you guys! Just got it today. Don't mind the mess in the background, I've been going through everything in the garage lately and giving it a well deserved douch.

Fanman. I like the chip tray idea, I'll stop tomorrow and see what I can come up with.

Mark, I'm fairly new to machining, I bought a mini mill the end of last year and quickly decided I wanted something bigger. I decked it out with full igaging DRO, spindle light, and air chip removal. I decided to sell it and took the money from that and bought the big boy in the pictures here. I do know how to tram, square a vise, adjust gibs and backlash, use an edge finder, pretty much all the basics. My mini mill I had was trimmed and squared to .0005. I'm a finish carpenter by trade, so being very precise is kind of my thing. No pictures of the stand just yet, I'm waiting for paint to dry. Hopefully in the next couple days I'll get this bad boy apart and moved onto the stand and reassembled. I'm VERY excited to run it!!

What size vise are you guys using for this machine? I have a 3" kurt clone from my mini mill but I want to buy a bigger one. I was thinking either a 5" or 6". Would 6" be overkill in your opinion?

Here's a few pics of my mini mill for all you picture lovers.