-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rockwell Mill, Head Stock worm gear?

- Thread starter 38super

- Start date

- Joined

- Dec 12, 2016

- Messages

- 493

Sorry,but no help on the tap.

I may need to do something similar at some point, was thinking that something other than aluminum should be used for the ring gear (brass?).

Any thoughts?

I may need to do something similar at some point, was thinking that something other than aluminum should be used for the ring gear (brass?).

Any thoughts?

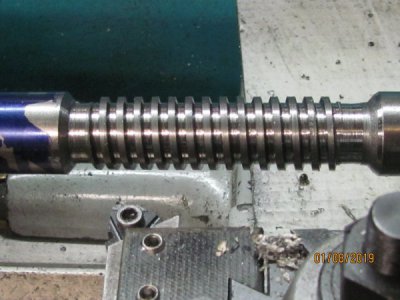

Making a 7/8-5 cutter, hope I have enough propane for kasenit treatment. Might be time to build a furnace/smelter and melt all the aluminum shavings into ingots. Aluminum (6061 - 7075) is OK, who ever used this machine before did not understand the headstock clamps have to be loosen to rotate the head. Seems like one job begets another.

- Joined

- Dec 27, 2014

- Messages

- 4,056

Is the gear stripped all the way around? Can it be rotated 180º and reused?

Gear and cast gear housing are both cracked. Serious gronk was applied. Will post a few pics of work in progress. Got a lead screw prob with SB13 gear box, gotta fix that to finish the 7/8-5 tap blank. $h*t snowball.

edit: The original worm gear has the look of cast aluminum, crack looks grainy. Bet it made noise when it cracked.

edit: The original worm gear has the look of cast aluminum, crack looks grainy. Bet it made noise when it cracked.

Last edited:

Bad and good news. SB13 gear box SNAFU, lost the feed in the middle of making the hob (0.078" thd depth, need 0.115"). Milled 4 cutting faces and applied Kasenit. 12 minute heat up with a propane weed burner. Gear blank rotated on used M/C wheel bearings (mistake). First try was very hard for the hob to rotate the gear blank until a cut is established. Inconsistent tooth profile on gear blank, suspect a bad (stretched) bearing cage.

Good news, the hob will work but needs improvements. Bad, need a better way to hold the gear blank.

Set up.

Set up. Bad teeth.

Bad teeth. Cutter / gear blank engagement.

Cutter / gear blank engagement.

I'm sure experienced machinist are enjoying my rookie escapades, can't pass up a learning experience no matter how bad it looks.

Good news, the hob will work but needs improvements. Bad, need a better way to hold the gear blank.

Set up.

Set up. Bad teeth.

Bad teeth. Cutter / gear blank engagement.

Cutter / gear blank engagement.I'm sure experienced machinist are enjoying my rookie escapades, can't pass up a learning experience no matter how bad it looks.

- Joined

- Apr 30, 2015

- Messages

- 11,291

Looks like you are nearly there, one more blank on some better bearings should give a good part

What about the housing? Braze? (I assume it's cast iron)

mark

What about the housing? Braze? (I assume it's cast iron)

mark

Was watching Jody on Welding Tips n Tricks, trying to source aluminum/bronze filler rod.

FYI: Gear blank base metal machines like 6061, stringy. For SoCal hobby machinist, try Max Industries in Gardena, best source for aluminum sheet, plate & round (all extruded, no cast). Not associated with this business.

FYI: Gear blank base metal machines like 6061, stringy. For SoCal hobby machinist, try Max Industries in Gardena, best source for aluminum sheet, plate & round (all extruded, no cast). Not associated with this business.

Last edited: