- Joined

- Nov 14, 2016

- Messages

- 2,999

Good info. yeah thats how I tell them apart the beefed up knee on the 30's. The gent I bought my mill from had an 8520 in his museum basement. I went to it like a magnet. It's a bigger mill than I realized in photos, seems very well built. I still want one. I saw one go on ebay a year ago for 1500 that was in decent shape. There are three 8520 on right now and one 8530, all around 3K. Whats strange is that a year ago none of them were over 2K. They seem to have shot up in price. I think bc the hobbyist market has become more aware of what they are. But just a guess. No Rockwell's for sale on epay right now. They are a harder find. I use MT2 on my lathe tailstock so I agree MT2 is not an issue. How large of shank can you grab? With R8 they make 1" but people say dont put much of a load on them. My largest will be a 7/8 collet altho dont own anything past 3/4. So what kind of work do you use your Clausing on?

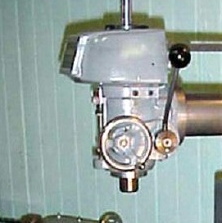

The fine feed uses a removable hand wheel, that slips over a stud in front of the course feed lever. The hand wheel interferes with the travel on the lever so you usually see it off when not being used which just leaves a stud showing.

MT2 collets go up to 1/2", but I also have an MT2 adapter that fits my ER collet chucks from my lathe.

I don't know when production ended for these Rockwell and Clausing mills, but think it is probably safe to assume early 1980s at the latest, and probably some time in the 1970s. Mine was made in the mid 1960s which seems to be very common. Compare that to Bridgeport and clones which have been in production to the present (BPs were also likely made in much larger numbers) and the rising prices are probably just caused by a diminishing supply of machines. I probably see 100+ BP style mills for every small knee mill offered on Craigslist. Clausing, Rockwell and Millrite have a lot more name recognition so command higher prices. Just like cars when a low volume car sells for a high price at auction, and everybody with a rusted out '72 Dodge Dart thinks they are sitting on a gold mine. Same thing when a particularly nice or well tooled example sells at a high price on Ebay, everybody suddenly thinks theirs is worth more than it probably is.

I occasionally see an odd mill of similar size that often sell for much less, older imports and vintage USA. Probably as just as good for a small hobby machine but nobody knows what they are. The shop where I took welding classes had a neat 1980s Taiwanese mill, it looked just like a 1/2 scale Bridgeport so not much bigger than my Clausing, but the brand name Liang Wai isn't going to cause a stampede of buyers. There was a Rotex horizontal / vertical mill recently on CL only asking $700, that is about the same size as these mills. If I didn't already have a mill, I probably would have been satisfied with that one at almost 1/4 the usual asking price.

My other mill is a Sherline so the 8520 feels like a big mill to me.

I got into machining to make model parts, so I got a Sherline lathe and mill. They are still the ones I use the most, but my interests grew in size so I started looking for some bigger machines. Still mostly interested in making models but the machines themselves and how to use them also fascinates me. I have a local group of enablers and this site so what started off as a "I just need a mini-lathe and mill" turned into a basement full of cast iron. It seems I do a lot less making of things lately and more making room for things.

I have a little more work ahead of me arranging things and getting a few of the machines ready to work, but I think I'm almost ready to start making stuff that isn't for one of the machines again. My welder has been getting a lot of work building bases for some of my recent additions.

I started taking welding classes in 2019, and I don't know how I made it all this time without a welder. I'm not that very good at it yet, but I love being able to glue metal together.

Last edited: