-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

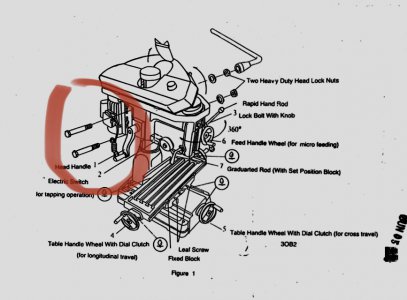

Rong Fu Clone (HF33686) head movement question

- Thread starter Tomzo

- Start date

- Joined

- Jul 27, 2021

- Messages

- 221

Yes - the "heavy duty head lock nuts". I use a 1/2" lug nut wrench that has an extension and I have to have the full ~24" of that to get enough torque to get it tight. I may just get a battery powered impact wrench, but it seems that it should not take quite that much to get the thing to stop moving. When I replace the motor I will take a better look as it is up against the wall now and it is hard to really see what is going on.

- Joined

- Apr 23, 2018

- Messages

- 6,525

Here you go, man!

I don't have time to teach everyone how to fish, so here is a free fish!

I don't have time to teach everyone how to fish, so here is a free fish!

RF-30 Clone Head Alignment Guide

Rob,- Now you have me going again, mine has two belts. Does three mean you have a power quill down drive?www.hobby-machinist.com

- Joined

- Jul 27, 2021

- Messages

- 221

Thanks - just ordered the set. Shipping on the studs was nuts from McMaster Carr so I got those from Amazon.Here you go, man!

I don't have time to teach everyone how to fish, so here is a free fish!

- Joined

- Apr 23, 2018

- Messages

- 6,525

They make a substantial difference in holding power, not to mention applying even clamping through the spherical flange nuts. Fixed my problems for good. My friend owns my old RF-31 now, and he's happy with it too. Fairly cheap fix. Let us know how it works out, sounds like you are seeing the worst of it (head movement) on your end.Thanks - just ordered the set. Shipping on the studs was nuts from McMaster Carr so I got those from Amazon.

- Joined

- Feb 1, 2015

- Messages

- 9,604

I have had my RF30 clone for more than forty years and never had a problem with not being able to tighten the head clamping bolts. I would pull the bolts one at a time and check/chase the threads. The nuts should spin on freely. While they're out,check the length of the thread. The P.O. may have replaced them with bolts with a shorter thread length. My bolts are 9" long and have 2" threads with a little less than half engaged. Finally, check the gap between the split halves for an obstruction that would prevent clamping. I tighten with a 13" box wrench. Typical torque is 30 -35 lb.ft.

- Joined

- Jul 27, 2021

- Messages

- 221

I have had my RF30 clone for more than forty years and never had a problem with not being able to tighten the head clamping bolts. I would pull the bolts one at a time and check/chase the threads. The nuts should spin on freely. While they're out,check the length of the thread. The P.O. may have replaced them with bolts with a shorter thread length. My bolts are 9" long and have 2" threads with a little less than half engaged. Finally, check the gap between the split halves for an obstruction that would prevent clamping. I tighten with a 13" box wrench. Typical torque is 30 -35 lb.ft.

Well I can't turn them more than one full turn when loosening. Must be really galled up. When my replacement bolts arrive I will get them off one way or another as they won't be going back on. I will also check the gap to make sure it is clear. Thanks

Sent from my iPhone using Tapatalk

- Joined

- Dec 26, 2015

- Messages

- 2,079

Sounds like a sloppily fitted gib.