- Joined

- May 9, 2020

- Messages

- 42

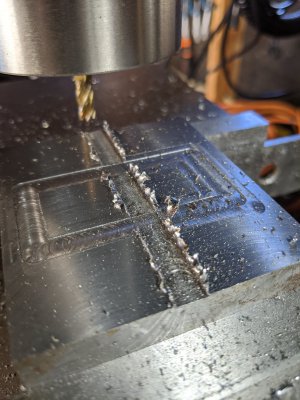

Ok, total N00b here. I have a brand new Grizzly G0619 with a max RPM of 1800. When trying to end mill using a .25" end mill HSS TiN, I get all sorts of rough edges. This particular cut was .002 deep at about 5.5 inches per minute. According to my handy (but I am not so sure I believe it) app that shows my feed and speed rate according to the max RPM my machine is capable of. So, what is happening here and why? I am practicing using my new DRO and even the rectangle needed to be shaved of rough burrs. Frustrating to say the least.

Attachments

Last edited: