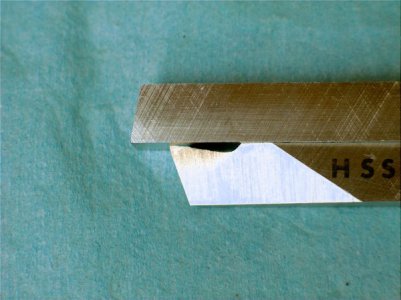

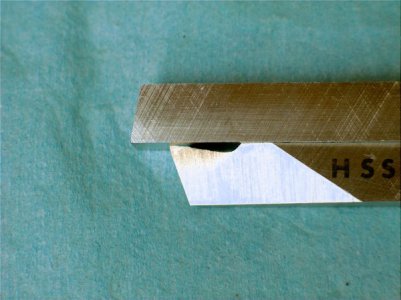

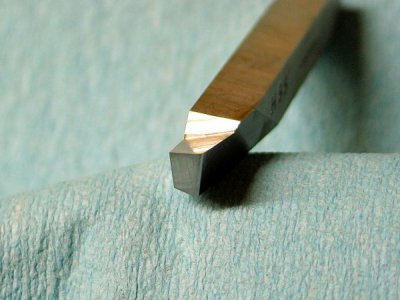

photos!! the first three are top then side then front, the next one is on the other end of one of the first but the same top -> side -> front

Okay, that explains a lot. Looks to me like the sequence is back side, top and front. Let's take them one at a time. Before we go on, let me be very clear. I am not criticizing YOU; I am critiquing the tool and telling you how I would fix it, okay?

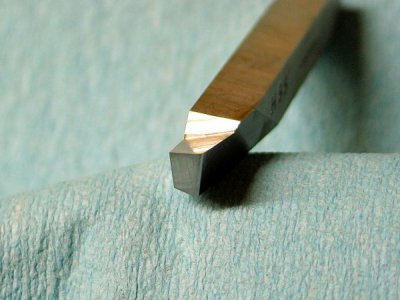

Let's look at the bottom tool in the first pic. See how the top of the tool slopes downward towards the tip? That is called negative rake and it greatly increases the cutting forces the tool produces; this is not good. What you need is for the top of the tool to slope the other way, so that the tip is higher in front. See the pic below to see what I mean.

The same tool in the third pic shows that downward slope; this is called negative back rake. We can also see that the top is slightly angled toward the back side of the tool; this is called side rake and the angle on your tool is going in the right direction but it will work better if the angle is greater like this:

The relief angles, those sloping angles below the cutting edge, need to be at least 8 degrees or so; 12-15 degrees will work even better.

You also want to put a small nose radius at the very tip, like this:

Once you correct all the angles, get them smooth and flat with your diamond hones. You want the edges sharp enough to slice newsprint. Stone the nose radius on with the hones; it is easier to do it that way instead of using your grinder.

The second tool has a better overall outer shape but the tool angles are difficult to see. It looks like it doesn't have much in the way of relief or rake angles; this tool will not cut well.

Looking at these tools, it isn't surprising that you're having trouble turning steel. The good thing is that the problems are simple to correct in a few minutes. I suggest you have a look at this discussion first so you have an idea of what you're trying to achieve:

https://www.hobby-machinist.com/threads/how-to-grind-a-hss-turning-tool.52581/. Then try to correct your tool angles and post pics so we can refine them. Once we get the tool angles right, you'll have a much easier time turning. The tool will cut more accurately and finish much better, trust me.