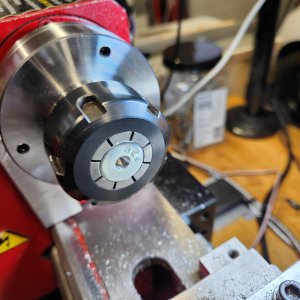

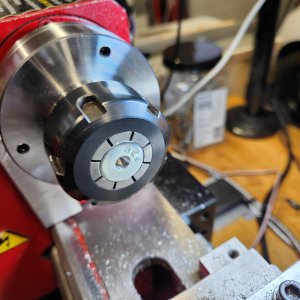

I decided to try a variation of the filing button, here's an overview.

The part to be rounded is 3/4" wide with 1/4-24 holes, found 3/4" OD washers with 3/16" holes, drilled the holes out to 1/4". Bolted the washers, marked arcs and cut off the corners on the bandsaw. Ground the high spots with the bench grinder. Hardened the washers with a MAP torch and water quench. Filed the piece around the washers, finished with 400 grit in the P-C sander. The result is good 'nuff for this project.

A few details:

1) Center drilled a piece of 3/4" stock as a guide and drilled the washers for a close fit.

2) Marked the cut lines with a Sharpie.

3) Cut the fat with the bandsaw.

4) Bench grinder, filed and sanded.

There's a bonus in this approach for me; after filing, I've cancelled my gym membership, filing is far more work, and vastly more rewarding

.