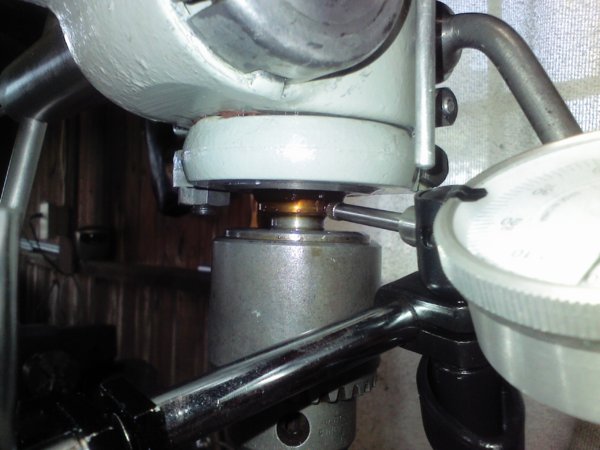

Need some help on this one...Recently undertook a bit of a restoration on a Delta DP220 drill press. Now that everything in cleaned, repainted, & put back together I checked the runout using a 1/2"in. & 1/4"in. drill bit in the Jacobs 6A33 chuck and it came in at a whopping .032 !! So I'm thinking I either have a bent bent spindle or bad chuck, not sure which at this point. I took a measurement with a DI at the lower bearing drive collar (I believe that's what it's referred to as).....This was as close a reference point as I could could get the DI into to try to measure the spindle. Would this point give me an accurate indication of whether the spindle was bent ?? The DI showed .002 runout there.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Runout on Delta DP220 ??...

- Thread starter 56type

- Start date

- Joined

- Jul 2, 2014

- Messages

- 7,594

I see you are talking about the spindle where you are measuring the .002" runout. If so, good! Your drill press is probably OK, at least that far down. So, the problem is in the spindle taper, the chuck or in the test bar. A drill bit does not make a test bar. They are easily bent, and often have runout even when new. A cheap and good substitute is a dowel pin. They are hardened and ground to size, and are plenty accurate enough to test a drill press with. The next issue can be the jaws of the chuck, from abuse, drills spinning in the jaws, crashed parts, etc. The connection from spindle taper to chuck taper can be damaged from coming loose and being galled at some point in time. Only way to know is to remove the chuck and check the runout on the spindle taper itself, and inspect for less than perfect surfaces mating the spindle and chuck together. Drill presses are not precision machines, so do not get carried away, but .032" is way too much runout! Several thousandths runout is normal and acceptable for most things a drill press does.

Thanks...OK, I just removed the chuck and the surface of the taper is in great shape (no burrs, nicks, gouges or score marks). However it does indicate .010 runout on the DI. I seem to recall reading somewhere that it should be around .003 or less, no more the .005, does that sound about right ?? Thanks for the help.

Restored this one since it was an older machine and had the split-front head casing that allows removal of slop in the quill, unlike my Ryobi DP120 where there is no effective way to remove the play found in the quill. I'd just like to get it in spec. and running within the limits of it's performance. Still looking for a mill that fits my needs, for the right price.

Restored this one since it was an older machine and had the split-front head casing that allows removal of slop in the quill, unlike my Ryobi DP120 where there is no effective way to remove the play found in the quill. I'd just like to get it in spec. and running within the limits of it's performance. Still looking for a mill that fits my needs, for the right price.

- Joined

- Jul 2, 2014

- Messages

- 7,594

Yes, .010" is too much. You may be able to straighten it (CAREFULLY!) after taking it off of the machine. It is also possible to re-cut the taper, but that is a fussy job that requires a grinder setup that can work to tight angle and tolerance, or the chuck will keep falling off afterwards. If you straighten it, go slowly and set it up so you are not bending the entire spindle, keep the spindle itself straight and gently nudge the JT taper back to running true. First, cause no harm... It is easy to ruin your drill press doing this, so go slowly, think ahead, and be careful.It might actually be easier to do the job with the chuck still in place, which would also make it easier to test the results.

- Joined

- Nov 14, 2014

- Messages

- 851

Your chuck is likely a major contributor for your runout. Wear and tear in the jaws maybe. Usually .003" runout is pretty good at the spindle. You might be able to beat this with a new, good quality chuck. I've had two DP 220 Delta DP's. My current one was made in 1939, and I measure runout at .001" with the chuck in place. Now, it is in pristine condition, having had one Boeing engineer-hobbyist type owner since new. My earlier one, was nice and clean, but had done its share of work in commercial shops. The runout on it was .012". Mostly from the chuck. If I remember correctly, I measured the spindle runout at around .003" without the chuck.

So my best guess is a medium to good quality chuck will put you into the .003 to .005" range, quite possibly even less!

Glenn

So my best guess is a medium to good quality chuck will put you into the .003 to .005" range, quite possibly even less!

Glenn

- Joined

- Dec 20, 2012

- Messages

- 9,422

Did you happen to change the spindle and drive sleeve bearings? In my limited experience, the bearings are where most of the run out will occur (not even looking as far as the chuck yet). It is not that common for the spindle itself to bend but the taper can be damaged or the chuck installed poorly. The drive sleeve can also be worn and if that is the problem then the only recourse is to repair or replace it.

My approach is to use a somewhat junky dial test indicator and run it inside the taper with the machine running at low speed (taper cleaned, of course, and the indicator tip running on a clean surface). If the bearings are bad, you will see a lot of bouncing of the needle. It is difficult to tell if the spindle bearings or the drive sleeve bearings are the cause because the spindle is located at the top by the drive sleeve bearings. Best bet is to change the spindle bearings first and see, OR change both and be done with it.

If you do change bearings, use good ones. I recommend Nachi deep groove bearings. These can handle high radial and axial loads and their cost is quite reasonable. They hold up well; my drill press spindle runs with 0.0005" TIR.

My approach is to use a somewhat junky dial test indicator and run it inside the taper with the machine running at low speed (taper cleaned, of course, and the indicator tip running on a clean surface). If the bearings are bad, you will see a lot of bouncing of the needle. It is difficult to tell if the spindle bearings or the drive sleeve bearings are the cause because the spindle is located at the top by the drive sleeve bearings. Best bet is to change the spindle bearings first and see, OR change both and be done with it.

If you do change bearings, use good ones. I recommend Nachi deep groove bearings. These can handle high radial and axial loads and their cost is quite reasonable. They hold up well; my drill press spindle runs with 0.0005" TIR.

Your chuck is likely a major contributor for your runout. Wear and tear in the jaws maybe. Usually .003" runout is pretty good at the spindle. You might be able to beat this with a new, good quality chuck. I've had two DP 220 Delta DP's. My current one was made in 1939, and I measure runout at .001" with the chuck in place. Now, it is in pristine condition, having had one Boeing engineer-hobbyist type owner since new. My earlier one, was nice and clean, but had done its share of work in commercial shops. The runout on it was .012". Mostly from the chuck. If I remember correctly, I measured the spindle runout at around .003" without the chuck.

So my best guess is a medium to good quality chuck will put you into the .003 to .005" range, quite possibly even less!

Glenn

I thought so initially too. Here's what I've done so far... Removed the chuck and set up a DI with the plunger reading off the minor diameter of the Jacobs taper. That's where I'm coming up with the .010. I marked the High (.010) and the Low (.000) with a blue sharpie but not sure where to go from there as far as a setup to keep everything else straight while working to straighten the possible bent portion...

Did you happen to change the spindle and drive sleeve bearings? In my limited experience, the bearings are where most of the run out will occur (not even looking as far as the chuck yet). It is not that common for the spindle itself to bend but the taper can be damaged or the chuck installed poorly. The drive sleeve can also be worn and if that is the problem then the only recourse is to repair or replace it.

My approach is to use a somewhat junky dial test indicator and run it inside the taper with the machine running at low speed (taper cleaned, of course, and the indicator tip running on a clean surface). If the bearings are bad, you will see a lot of bouncing of the needle. It is difficult to tell if the spindle bearings or the drive sleeve bearings are the cause because the spindle is located at the top by the drive sleeve bearings. Best bet is to change the spindle bearings first and see, OR change both and be done with it.

If you do change bearings, use good ones. I recommend Nachi deep groove bearings. These can handle high radial and axial loads and their cost is quite reasonable. They hold up well; my drill press spindle runs with 0.0005" TIR.

I was doing some searching last night and ran across an outfit called Hammerscale that seems to specialize in resto. of the vintage Delta machines. On their site is listed a spindle rebuild service for $135, which includes new bearings and and truing up the Jacobs taper. The bearings themselves list for $90 at that same site. Should I go ahead and dole out the cash to have it done or is this something I can do myself fairly inexpensively ?? Reason I ask is I have zero experience truing up spindles and wouldn't want to damage the spindle trying to press out/off the old bearings, turning a slightly damaged part that could be salvaged into scrap that would have to be replaced. Thanks.

http://www.hammerscale.com/HTML/Products/DrillPress/DP220B.html

- Joined

- Nov 14, 2014

- Messages

- 851

This vendor looks like a good deal. If it where me, I would send the spindle in for rebuild and new bearings. Having never done that before, and without the tooling needed, you might be in a very high risk of area for making things worse, with DYI.

Glenn

Glenn

- Joined

- Dec 20, 2012

- Messages

- 9,422

I was doing some searching last night and ran across an outfit called Hammerscale that seems to specialize in resto. of the vintage Delta machines. On their site is listed a spindle rebuild service for $135, which includes new bearings and and truing up the Jacobs taper. The bearings themselves list for $90 at that same site. Should I go ahead and dole out the cash to have it done or is this something I can do myself fairly inexpensively ?? Reason I ask is I have zero experience truing up spindles and wouldn't want to damage the spindle trying to press out/off the old bearings, turning a slightly damaged part that could be salvaged into scrap that would have to be replaced. Thanks.

http://www.hammerscale.com/HTML/Products/DrillPress/DP220B.html

I suppose it depends on if you find excessive clearance in the current bearings. If the bearings are the source of the run out then they need replacement. I cannot tell if the replacement bearings just have a sleeve pressed into standard bearings or if the snout is part of the inner race. I suspect it is a sleeve; if so, you might be able to fit your old sleeves into a better quality bearing for a lower price.

I also think you should check the jacobs taper with an indicator to see if it really needs truing. If it does and you don't feel comfortable grinding it yourself then you can have them do that. I have not found jacobs tapers to be particularly susceptible to damage - I would check it first.