- Joined

- Apr 14, 2022

- Messages

- 10

Good afternoon

Hope I am posting in the right section if not please advise as to where this needs to go.

I recently got a Sanco Mill from a friend of mine. He said the machine never worked in his shop and I know now why he never got it running.

I hooked it up in my shop and as soon as the power is turned on a fuse inside the electrical cabinet blows.

When the door of the electrical box is open the machine has a safety switch and nothing besides the switch is powered. After the switch is closed a 10amp glass fuse nearly explodes.

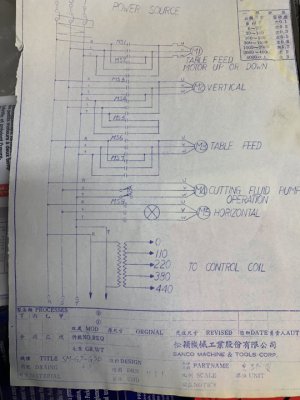

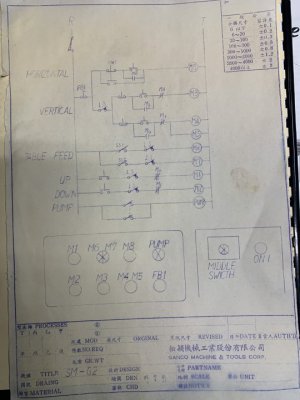

The switch is connected to a transformer and perhaps acts like the main switch to turn on all the gizmos this machine has to offer through this transformer. The switch is connected to the “0” (zero) pin of the transformer. When I measure continuity between all the pins on the transformer they all have continuity to each other. This makes me think that the transformer is bad.

I attached an image of the transformer and I do believe this is the culprit. Maybe measuring it this way is not correct and somebody could provide some help here. I would highly appreciate it. This transformer also has no other information but the name “San Gom” on it. Not clear where to find a replacement for this kind of transformer.

Any pointers would be greatly appreciated.

Thank you to all in advance.

Have a great weekend

Best Oliver

Hope I am posting in the right section if not please advise as to where this needs to go.

I recently got a Sanco Mill from a friend of mine. He said the machine never worked in his shop and I know now why he never got it running.

I hooked it up in my shop and as soon as the power is turned on a fuse inside the electrical cabinet blows.

When the door of the electrical box is open the machine has a safety switch and nothing besides the switch is powered. After the switch is closed a 10amp glass fuse nearly explodes.

The switch is connected to a transformer and perhaps acts like the main switch to turn on all the gizmos this machine has to offer through this transformer. The switch is connected to the “0” (zero) pin of the transformer. When I measure continuity between all the pins on the transformer they all have continuity to each other. This makes me think that the transformer is bad.

I attached an image of the transformer and I do believe this is the culprit. Maybe measuring it this way is not correct and somebody could provide some help here. I would highly appreciate it. This transformer also has no other information but the name “San Gom” on it. Not clear where to find a replacement for this kind of transformer.

Any pointers would be greatly appreciated.

Thank you to all in advance.

Have a great weekend

Best Oliver