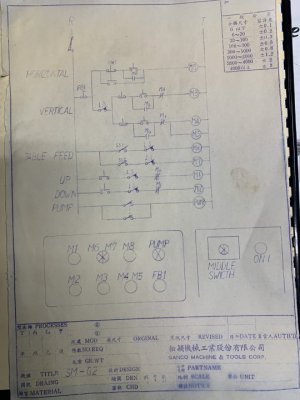

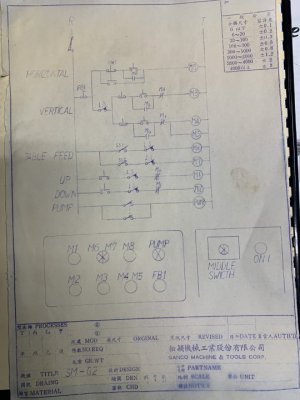

An auto-transformer would not show as two separate windings, but who knows how they draw the schematic. If there are no other connections to the transformer than that could be true. It indicates that they feed the control coils, so if you follow the yellow wires to their destination, then it might be that there is a jumper/selector which is used based on the feed voltage to the machine, as it came in both a 220 and 440V version (and possibly other voltages). The Control switches show they are connected to R and T, this could be direct power or from the transformer. You need to follow the transformer wires to see where they connect. I see two smaller glass fuses at the top of the cabinet which I assume are protecting the transformer, you should be able to remove the fuse and ohm out the other end of the connections as they should be 0 ohm. Without mapping it out you can't determine where there is an overload/short. It is also possible that the fuses are wrong type, sometimes on the input side of a transformer one will use a slow-blow because of the turn-on inrush. There are manuals on this model, not cheap and not sure it will show you much more electrically, but may be worth it in the long run. Can also call Jet and see if they have one for their version.

There is a second part to the diagram which is the control panel description, the right side corresponds to M1-8 which refers to the perspective contactor, MS1-MS8. NS1/MS2 is table knee motor (M1) up/down, these are interlocked and also have limit switches, MS3 is the ventricle spindle motor (M2) which appears to have momentary buttons for on/off for FOR/REV with latching contactors interlocked between contactors, MS4/MS5 I assme is reverse and 2nd contactor might be for the dual speed motor. MS6/MS7 is a single switch assume self centering for the the table feed motor (M3) right/left, interlocked and with limit switches, MS8 is the horizontal motor (M5), forward only. Coolant pump motor is M4. FB1 is the stop button for the vertical and horizontal motors. The ON may be the power to the control circuit, would pop off the panel and see if the yellow wire supply power to the machine controls. It may also be that there is a main power contactor, but not shown on the schematic.

Interesting that there appears that ther are no thermal overload relays attached to the contactors or additional fusing protecting against a motor overload, and also on the main power input.