I seen your post. good info. i have a 612 that i converted to cable but with factory components. I'm using an original cable and its perfectly fine. No cracks or flaking.@akjeff thanks for all the pictures and dimensions. I created my own post and made sure to credit you.

Thanks again!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Saving a Harig Super 612

- Thread starter akjeff

- Start date

You're very welcome! Glad the info was helpful.@akjeff thanks for all the pictures and dimensions. I created my own post and made sure to credit you.

Thanks again!

- Joined

- Jun 29, 2023

- Messages

- 1

I recently came upon a Harig 612 and I am just putting it into service to replace my well worn Boyar Schultz 6x12.

While playing with it, the crossfeed cable came unspooled from the shaft and then I didnt know how it spools back up so I managed to snap it after spooling it incorrectly while testing the limits of travel.

I found the pictures in this thread most helpful and I have some of the 1/16" cable and crimp sleeves coming from McMaster and I think I'll be able to get it all fixed up.

While playing with it, the crossfeed cable came unspooled from the shaft and then I didnt know how it spools back up so I managed to snap it after spooling it incorrectly while testing the limits of travel.

I found the pictures in this thread most helpful and I have some of the 1/16" cable and crimp sleeves coming from McMaster and I think I'll be able to get it all fixed up.

Excellent! Glad that the photos helped out, and thanks for letting me know!I recently came upon a Harig 612 and I am just putting it into service to replace my well worn Boyar Schultz 6x12.

While playing with it, the crossfeed cable came unspooled from the shaft and then I didnt know how it spools back up so I managed to snap it after spooling it incorrectly while testing the limits of travel.

I found the pictures in this thread most helpful and I have some of the 1/16" cable and crimp sleeves coming from McMaster and I think I'll be able to get it all fixed up.

Just a follow up post to this thread. Since getting this grinder up and running, I've had a negging surface finish issue that I haven't been able to track down, until now. It's always had at least a hint of a "herringbone" type surface finish, and it would really jump out after hitting it with a flat stone. Drove me nuts.

Pulled the spindle, removed the motor( making note of the orientation of the Lovejoy coupler as its all balanced from the factory ) and found the rubber spider in the Lovejoy was mostly gone and the consistency of modeling clay! Found a NOS replacement on Ebay, and put it in this evening and did a test grind on a small block of 4140. Comparing it to a previous grind on a similar block with the same wheel looks promising. The spindle is now virtually silent, and taking a cut of a couple tenths up a half thou, I can't even feel it, and the sound level of the grind is way less than before. With the bad coupler, I could noticeably feel when the wheel was in the cut, and it was pretty loud. Basically with all that slop in the coupler, the wheel was being driven by an impact driver of sorts. There was just enough of the rubber left so there was never any metal on metal contact of the two halves of the Lovejoy. Pretty relieved to finally track down this last piece of the puzzle on this grinder.

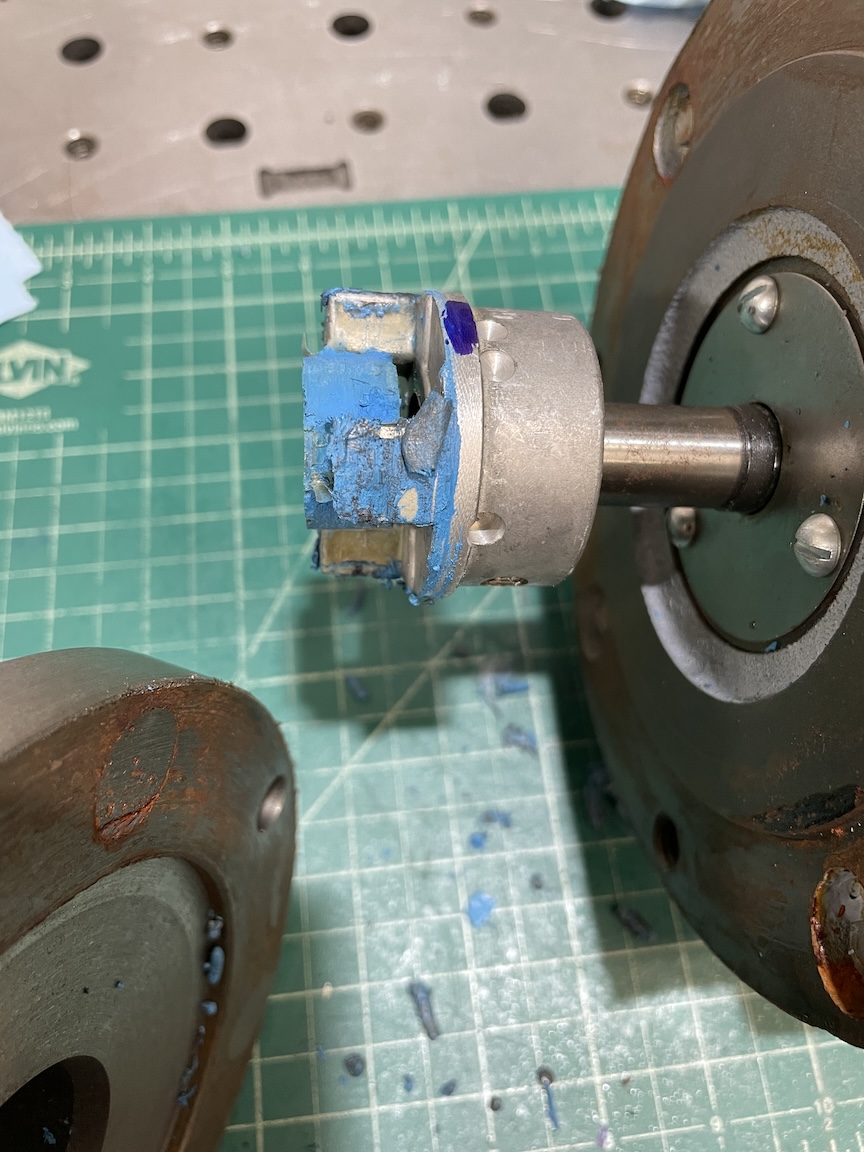

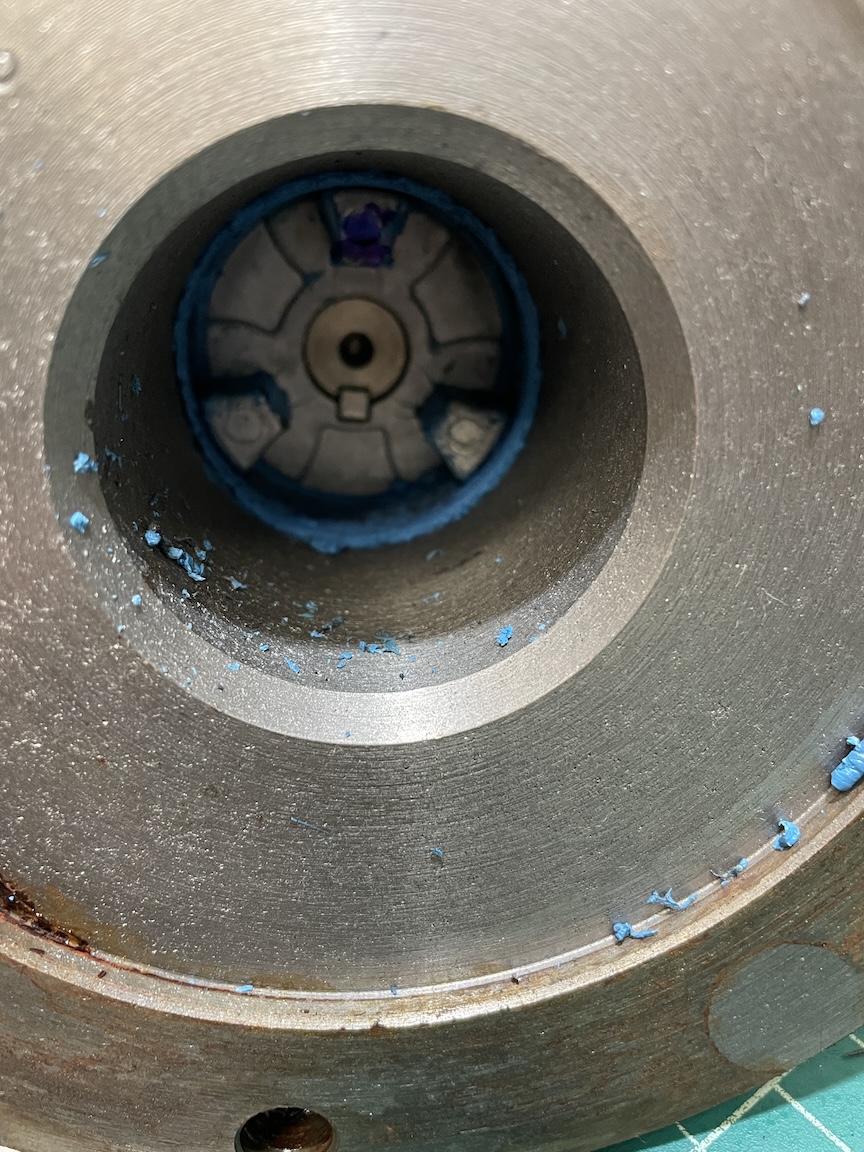

Here's what I found when I separated the motor from the spindle. This has to be the original coupler/spider, as the relief grooves in the spindle only had a single, very crisp set of witness marks from the five set screws that secure it. This area of the spindle is dry, and there was no evidence of any chemicals or lubricant in there, that could have attacked the rubber spider( or urethane, or whatever it was made of ). I guess just old age. It was clay like, and smeared and flung all over the cavity its in.

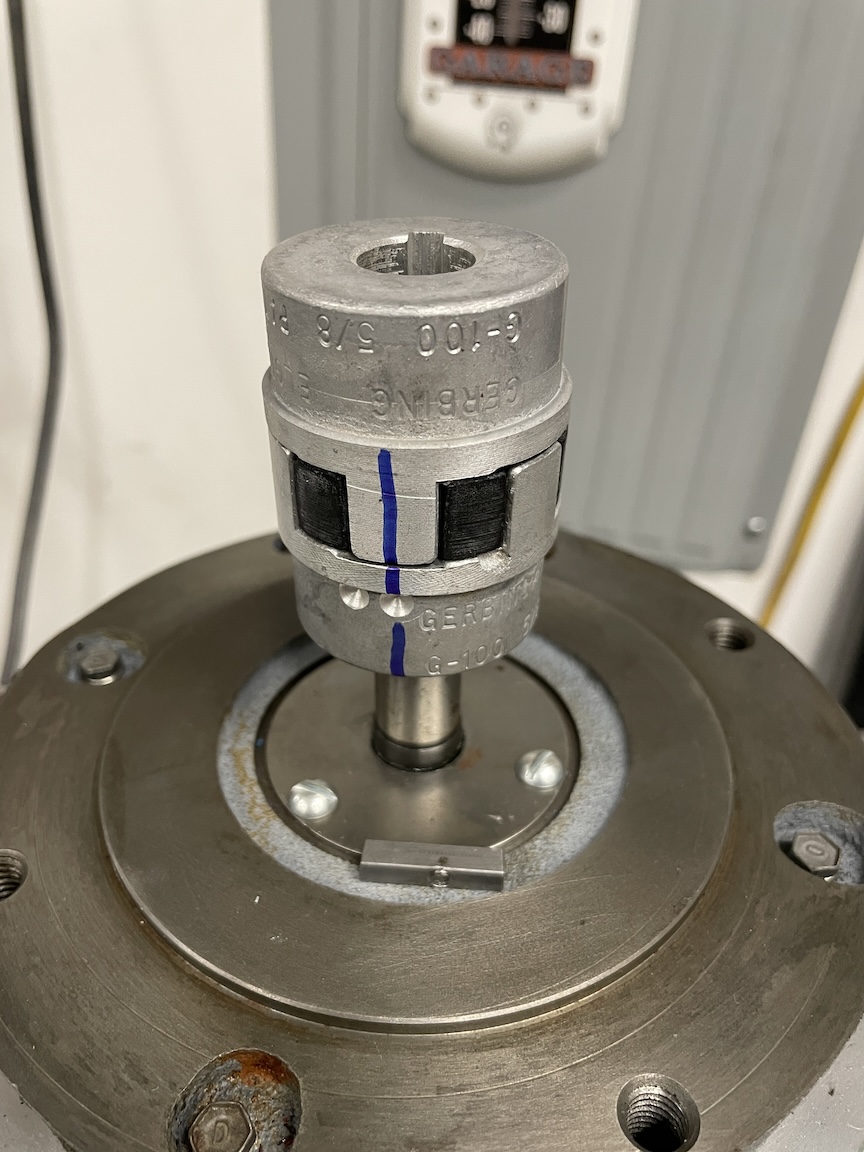

Here's the NOS replacement spider I fond on Ebay. Same manufacture/part no as the original. Fit right up.

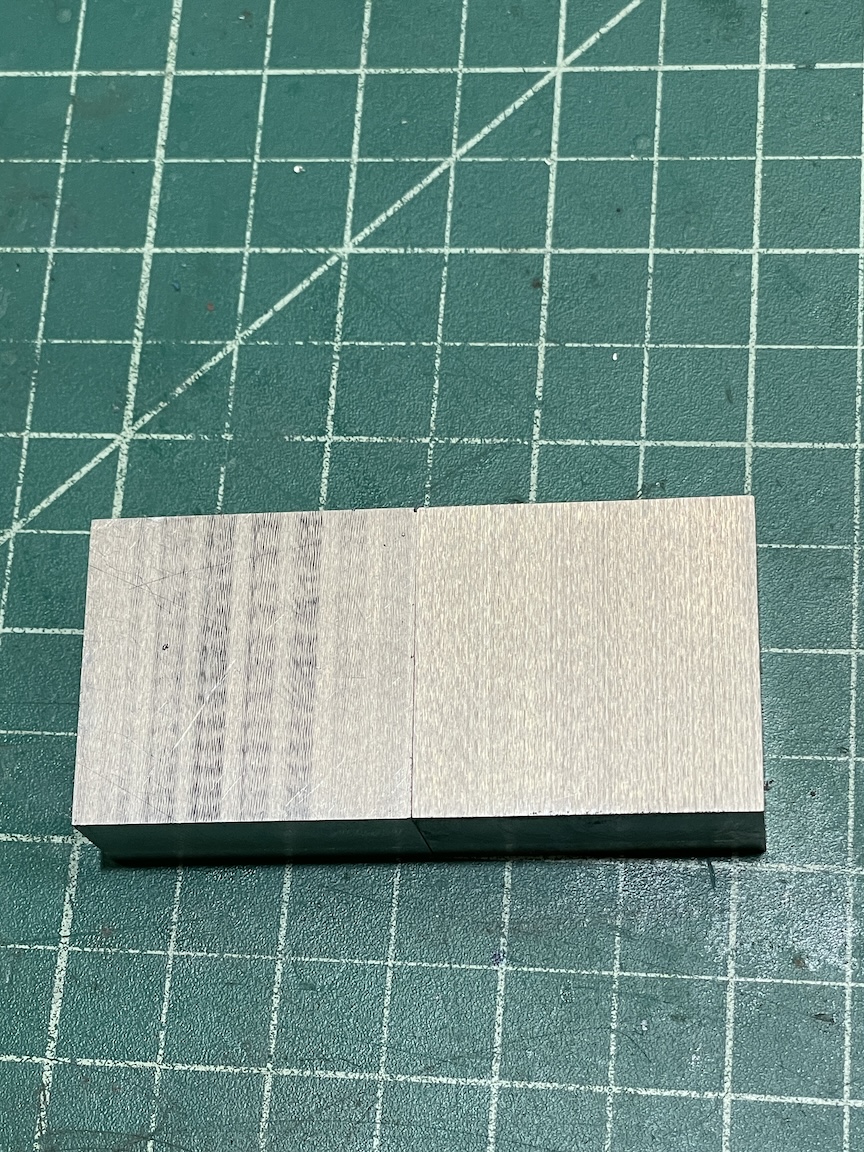

Before/after test blocks of 4140. Same 5SG46-J wheel, and both given a fresh stoning before the photo. In addition to the prominent lines on the before block on the left, it has ripple/chatter marks running perpendicular, that aren't showing up well in the photo. The appearance of the after block were unchanged after stoning. Pretty relieved to finally track this down.

Pulled the spindle, removed the motor( making note of the orientation of the Lovejoy coupler as its all balanced from the factory ) and found the rubber spider in the Lovejoy was mostly gone and the consistency of modeling clay! Found a NOS replacement on Ebay, and put it in this evening and did a test grind on a small block of 4140. Comparing it to a previous grind on a similar block with the same wheel looks promising. The spindle is now virtually silent, and taking a cut of a couple tenths up a half thou, I can't even feel it, and the sound level of the grind is way less than before. With the bad coupler, I could noticeably feel when the wheel was in the cut, and it was pretty loud. Basically with all that slop in the coupler, the wheel was being driven by an impact driver of sorts. There was just enough of the rubber left so there was never any metal on metal contact of the two halves of the Lovejoy. Pretty relieved to finally track down this last piece of the puzzle on this grinder.

Here's what I found when I separated the motor from the spindle. This has to be the original coupler/spider, as the relief grooves in the spindle only had a single, very crisp set of witness marks from the five set screws that secure it. This area of the spindle is dry, and there was no evidence of any chemicals or lubricant in there, that could have attacked the rubber spider( or urethane, or whatever it was made of ). I guess just old age. It was clay like, and smeared and flung all over the cavity its in.

Here's the NOS replacement spider I fond on Ebay. Same manufacture/part no as the original. Fit right up.

Before/after test blocks of 4140. Same 5SG46-J wheel, and both given a fresh stoning before the photo. In addition to the prominent lines on the before block on the left, it has ripple/chatter marks running perpendicular, that aren't showing up well in the photo. The appearance of the after block were unchanged after stoning. Pretty relieved to finally track this down.

I had the same motor coupling issue on the Harig Super 618 I just restored. (the restoration was documented on this forum). I still need to balance my grinding wheel before I do my final testing. I also just put a coolant system on it but have not documented that yet, but I will.

Look forward to seeing what you did for a coolant system. I went with a mist system, which I've been very happy with.I had the same motor coupling issue on the Harig Super 618 I just restored. (the restoration was documented on this forum). I still need to balance my grinding wheel before I do my final testing. I also just put a coolant system on it but have not documented that yet, but I will.

Look forward to seeing what you did for a coolant system. I went with a mist system, which I've been very happy with.

I too mostly use a mist system. A couple times I’ve used a bucket with settling area and a pond pump for flood coolant. Seems like the best approach is filtering flood coolant but I’ve not done so yet.