I acquired a 10 hp Ingersoll Rand T30 Compressor for my shop. It is 3 phase. I have phase converters already but I want to just run it on 220 single phase. My current compressor is a 1960's vintage 60 gallon I think . I am running it with a 220 single phase motor that I am going to put on the Ingersoll Rand and try. This motor has no tag and I bought it at an auction. We are thinking 10 HP but certainly bigger than 5 HP. I have run it for 15 years through the 2 pole pressure switch with no motor starter. Works fine. However, I wonder if the motor wont pull too many amps running the big compressor for the pressure switch to survive. The Ingersoll Rand is set up with the same model 2 pole pressure switch but it was used as a control circuit only and the compressor I assume had a motor starter that I did not get. If I set it up with a motor starter, how will it be wired through the pressure switch and what will one cost? The compressor was pretty well free but I am kinda on economy shop parts mode right now. I plan to use the pulley off the 3 phase on the single phase and try it at the same RPM. If it wont run the compressor that way (probably means its a 7.5 rather than a 10hp) I will try a smaller pulley. My air demands are not that great and I can certainly wait for it to build up with a smaller pulley. Again the motor has run the smaller compressor fine through the pressure switch but if it arcs and sticks the switch contacts it would run till it is switched off. I don't leave the compressor on unless I am working in the shop but i might walk to the house for a while and leave it on. How do you hook up a motor starter?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

School Me on Motor Starters

- Thread starter CJ5Dave

- Start date

- Joined

- Jan 2, 2019

- Messages

- 6,539

I’m probably not gonna be much help here but I’ve had great luck talking with the guys at the local industrial compressor service shop.

They know what you’re trying to do and usually have the parts on hand.

John

They know what you’re trying to do and usually have the parts on hand.

John

7.5 HP is my personal max on single phase it is quit a load on the electrical system and utility don't like it very much. I'm thinking if you can start it without a starter it maybe smaller then you think. Check the starting amps to make shire.

- Joined

- Apr 30, 2015

- Messages

- 11,328

Wow- not knowing what a file is. That's sad

- Joined

- Jun 12, 2014

- Messages

- 4,817

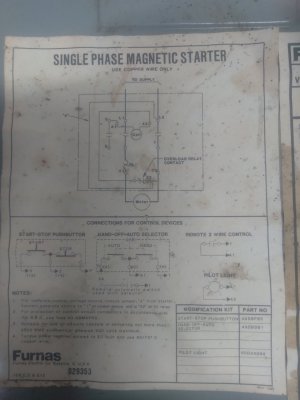

Usually on single phase compressors 5Hp (1750 RPM) and above, the commercial style use a motor starter. Basically a heavy duty contactor and an overload relay in a box. The pressure switch operates the contactor coil which is 240VAC. With single phase there is a jumper wire from T2 to L3. Power in is L1 and L2, motor connects to T1 and T3. Below is a similar model to what came with my Champion compressor which is single phase 5Hp. You would want to size the overload relay to the motor FLA. I also added a switch to my enclosure which interrupts the power going to the coil, so I have a local shut off for the compressor, I only turn on the switch when I am using the compressor, in case there is an air line break. There are different types of compressor pressure switches, the maximum rated that I have seen was 26A @ 240VAC, so 5 Hp.

EATON AIR COMPRESSOR MAGNETIC STARTER 7.5 HP 230 VOLT SINGLE PHASE B27CGF40B040 | eBay

PART#: B27CGF40B040. AIR COMPRESSOR MAGNETIC MOTOR STARTER. Compressor Motors. Magnetic Starters. Compressor Oil. Compressor Repair Parts. Vacuum Pump Parts. Air Compressors.

www.ebay.com

Eaton 10 HP Single 1 Phase 230V Magnetic Starter B27CGF45B057 Motor Control New | eBay

Industrial grade, heavy duty Eaton 10 horsepower single phase 220-240 volt magnetic starter with a steel housing, part number: B27CGF45B057. Eaton offers the most complete line of Definite Purpose (DP) contactors in the industry. Designed for air compressors, HVACR, and more, Eaton's motor...

www.ebay.com

- Joined

- Nov 14, 2020

- Messages

- 1,743

Years ago I worked for a compressor company, I think the pictures should tell the story.

I use a hand /off/auto switch depending on whether I am running continuously or starting and stopping the motor every cycle.

It turns out in " my case" running the motor continuously verses stopping and starting is cheaper and less loading of the electrical equipment.

I use a hand /off/auto switch depending on whether I am running continuously or starting and stopping the motor every cycle.

It turns out in " my case" running the motor continuously verses stopping and starting is cheaper and less loading of the electrical equipment.

Attachments

I ordered another split taper hub, mounted my mystery motor with the same 11 inch pulley on the compressor, hooked it to my 50 amp welder circuit, and it runs fine. Motor does not get even warm or trip thermal protector. It is pulling 31 or 32 amps running the big compressor. I hooked it up on the original 30 amp, 10 gauge wire circuit with 3 hp max pressure switch. Runs fine with the occasional spark at startup from pressure switch. Why does it not trip 30 amp breakers(one in breaker box, one in disconnect) when pulling 32 amps? 10 awg mc cable gets a little warm, but th braided awg cable from disconnect to switch gets warmer. Does braided wire carry less amps than solid? Gotta get a motor starter when I Find a deal.