S

SCLead

Forum Guest

Register Today

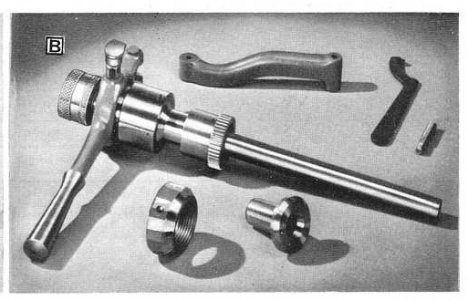

My lathe came with a lever type 5C collet closer and spindle adapter, but it's unfortunately not the SB closer, nor is it set up for my lathe. The draw tube is threaded for 5C collets, and the spindle adapter is 5C as well, so I think I'm going to modify the closer I have to fit the machine. I'm looking for a couple dimensions to help me down my road, so I'm hoping somebody here has one knocking around the shop. If anyone can provide photos of one mounted on a machine, that would help even more!

I understand I need a new extended gear to mate to the draw tube "drive." I suspect this might have to be matched to the closer I have, and a stock gear may not work for me. I don't currently have this gear, so I plan to cut one myself eventually (first hack at gear cutting, why not!) I am curious to see how the draw tube actually interfaces to the gear extension, as well as how the extension fits through the gear cover. I've read some folks have issues with gear covers clearing the extended nut, so I"m curious if I should expect similar issues.

The lever arm that connects the closer mechanism to the machine itself is a mystery to me. I have a pretty good idea how it connects and where, but I haven't found any images of the factory closer mounted to know if I'm even in the right ballpark. Assuming I can make it work, a center-center distance between the holes on this arm would be amazing, probably saving me several hours' worth of trial & error headache.

Alternatively, if anybody wants to offload a lever type collet closer they're not using, let me know

Thanks!

I understand I need a new extended gear to mate to the draw tube "drive." I suspect this might have to be matched to the closer I have, and a stock gear may not work for me. I don't currently have this gear, so I plan to cut one myself eventually (first hack at gear cutting, why not!) I am curious to see how the draw tube actually interfaces to the gear extension, as well as how the extension fits through the gear cover. I've read some folks have issues with gear covers clearing the extended nut, so I"m curious if I should expect similar issues.

The lever arm that connects the closer mechanism to the machine itself is a mystery to me. I have a pretty good idea how it connects and where, but I haven't found any images of the factory closer mounted to know if I'm even in the right ballpark. Assuming I can make it work, a center-center distance between the holes on this arm would be amazing, probably saving me several hours' worth of trial & error headache.

Alternatively, if anybody wants to offload a lever type collet closer they're not using, let me know

Thanks!

![WP_20180619_08_11_13_Pro[1].jpg WP_20180619_08_11_13_Pro[1].jpg](https://www.hobby-machinist.com/data/attachments/230/230937-c29d55d7292e2360688b57b2776f1e89.jpg)

![WP_20180619_08_11_24_Pro[1].jpg WP_20180619_08_11_24_Pro[1].jpg](https://www.hobby-machinist.com/data/attachments/230/230938-c7d50262eb28b3c6abfe2d65618cfee4.jpg)