- Joined

- Mar 20, 2014

- Messages

- 418

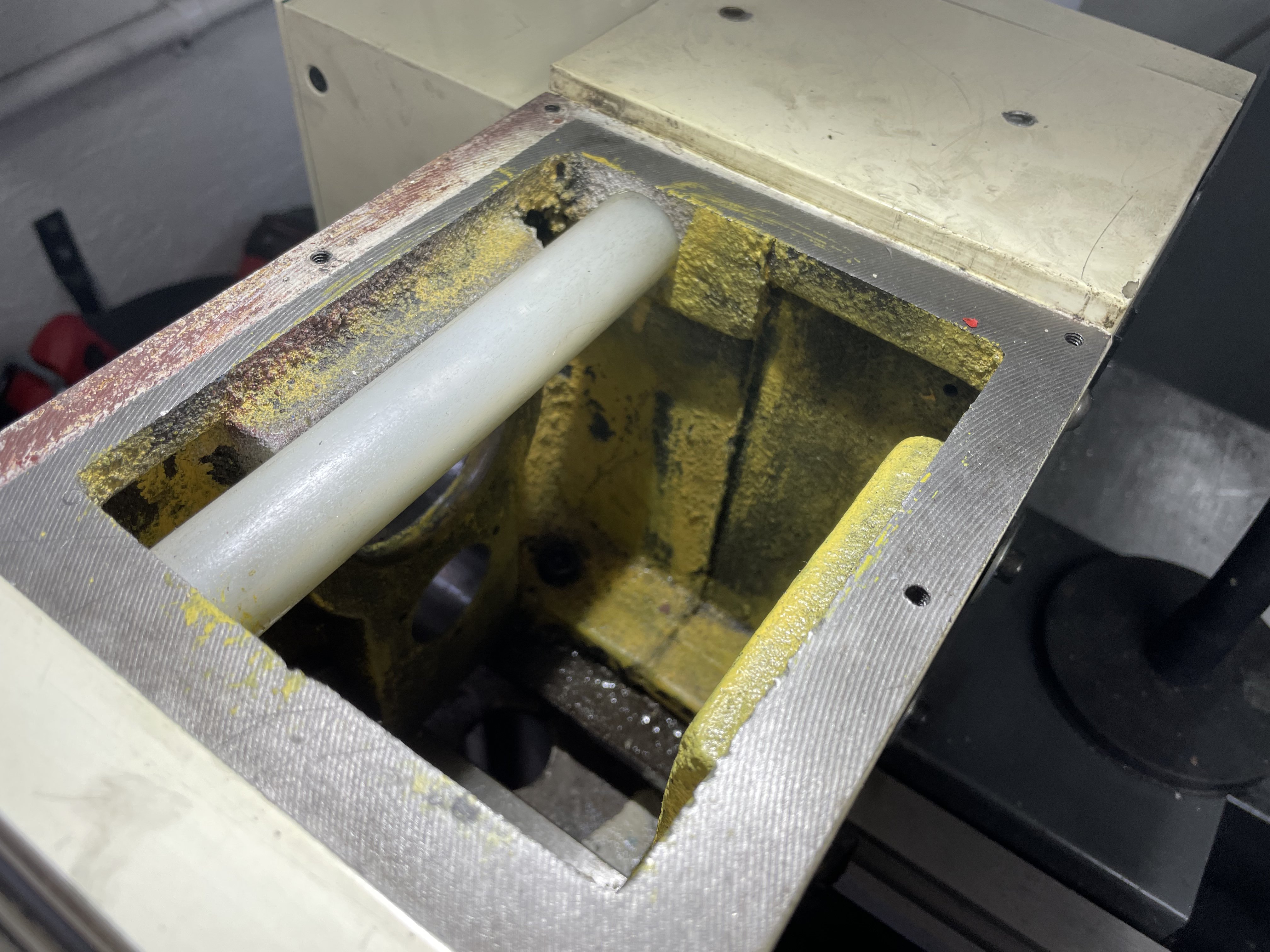

I‘m in the process of replacing all the headstock bearings in my Seig SC4. I’ve gotten the head stripped down fine:

The old bearings did not seem to be particularly well lubricated - the taper bearing from the front of the spindle just seemed to be running in a thin grey goop - the residue Im guessing of whatever was used at the factory.

I’ve ordered all new SKF bearings - better quality than stock no doubt, but I’d like to keep them that way. The front bearing is as I said a taper roller. The rear is a double shield deep ball bearing. Then there’s two smaller deep ball bearings with dual shields that run a small counter shaft that transmits power from the motor up to the spindle via two spur gears.

The headstock is open at the bottom, so there’s no oil bath. And there isn’t any provision to get oil to the bearing once everything is in place. The chuck mounting flange covers the front seal and bearing and the rear bearing is covered by a seal and the preload nuts. The two smaller bearings are somewhat accessible… but the shields sort of prevent getting any real quantity of oil into them, especially as most will just dribble out the front.

so, question is - has anyone else done this? What did you do for lubrication? I was thinking high quality grease for the taper, but then I read all sorts of posts about how it’s not the best, and oil is your friend. Which is great, if you can get it to the bearing.

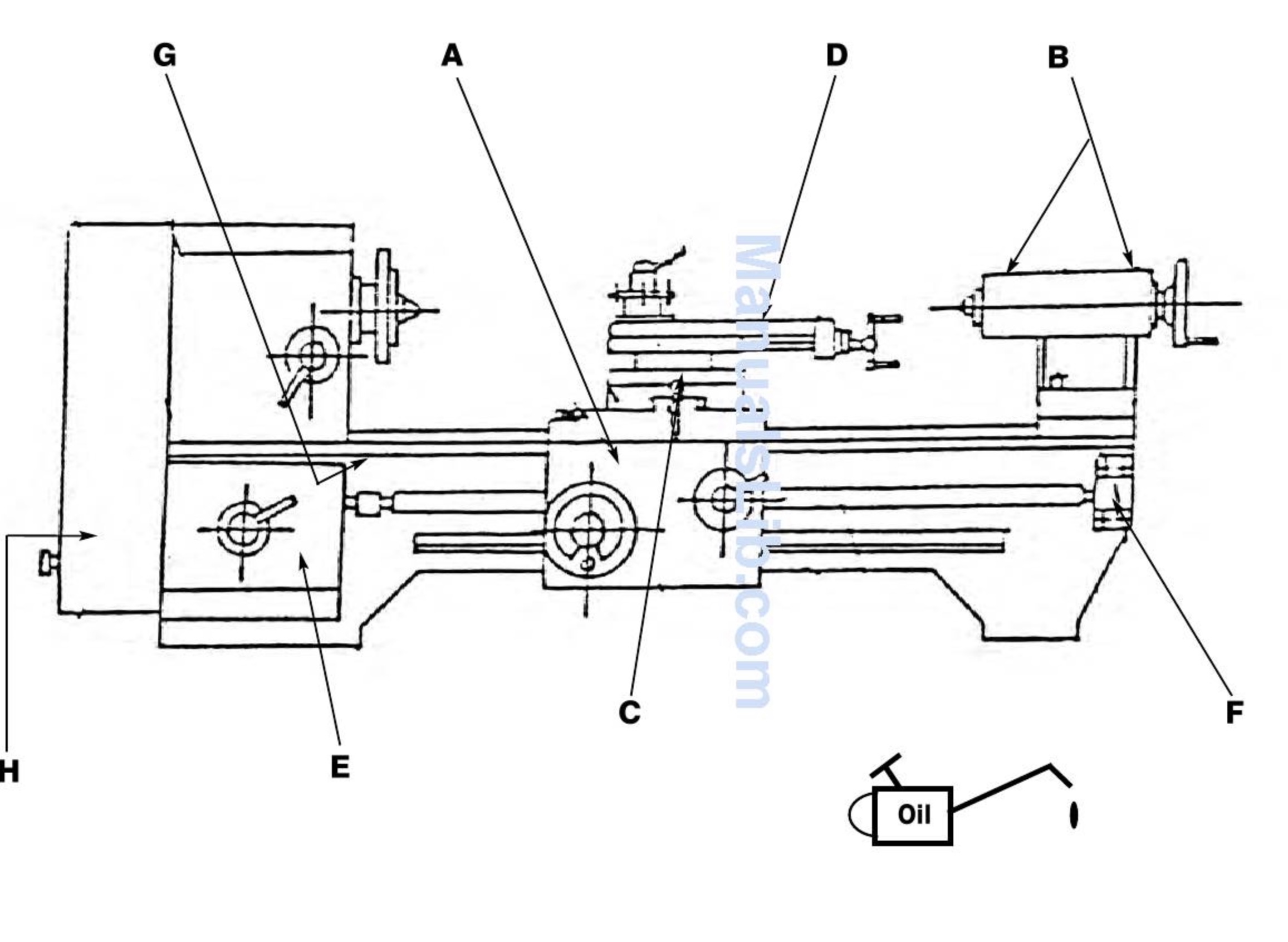

Any advice on this would be great. I mean, look at the official lubrication chart. Not that helpful, eh?

The old bearings did not seem to be particularly well lubricated - the taper bearing from the front of the spindle just seemed to be running in a thin grey goop - the residue Im guessing of whatever was used at the factory.

I’ve ordered all new SKF bearings - better quality than stock no doubt, but I’d like to keep them that way. The front bearing is as I said a taper roller. The rear is a double shield deep ball bearing. Then there’s two smaller deep ball bearings with dual shields that run a small counter shaft that transmits power from the motor up to the spindle via two spur gears.

The headstock is open at the bottom, so there’s no oil bath. And there isn’t any provision to get oil to the bearing once everything is in place. The chuck mounting flange covers the front seal and bearing and the rear bearing is covered by a seal and the preload nuts. The two smaller bearings are somewhat accessible… but the shields sort of prevent getting any real quantity of oil into them, especially as most will just dribble out the front.

so, question is - has anyone else done this? What did you do for lubrication? I was thinking high quality grease for the taper, but then I read all sorts of posts about how it’s not the best, and oil is your friend. Which is great, if you can get it to the bearing.

Any advice on this would be great. I mean, look at the official lubrication chart. Not that helpful, eh?