- Joined

- Dec 5, 2017

- Messages

- 464

I tried to search on this topic as I imagine it's a common question for beginners, but couldn't come up with a search phrase that led me to anything.

I managed to kludge together a set up to bore a hole in a piece of 5/16th inch round stock for a cotter pin but it was NOT pretty. It presented three major questions:

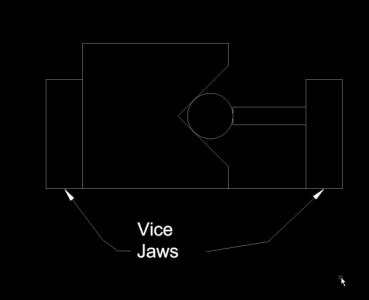

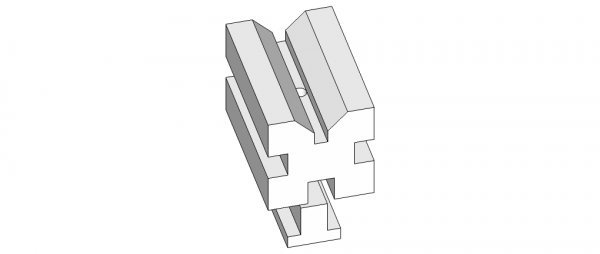

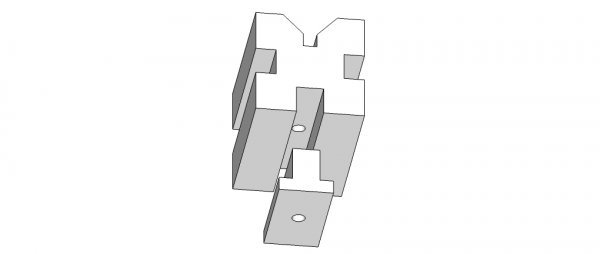

1. How do you clamp the v-block to the table on the mill? The slots on the sides are too small for a standard clamping kit. I can clamp on the top lip but that gets in the way of things pretty quickly. I milled a step on a piece of flat stock so it would fit in the side slot, but it wasn't very secure. For example, I wouldn't be comfortable milling a flat on a piece of round stock with that setup.

2. The stirrup clamp (if that's the right name) that holds the stock in the v-block gets in the way of the drill chuck pretty quickly. Somewhat better if I'm using a collet and a center drill but still not much clearance.

3. How do you ensure that the v-block is square on the table, or put another way, that the vee is parallel to the t-slots and aligned with the milling head?

I managed to kludge together a set up to bore a hole in a piece of 5/16th inch round stock for a cotter pin but it was NOT pretty. It presented three major questions:

1. How do you clamp the v-block to the table on the mill? The slots on the sides are too small for a standard clamping kit. I can clamp on the top lip but that gets in the way of things pretty quickly. I milled a step on a piece of flat stock so it would fit in the side slot, but it wasn't very secure. For example, I wouldn't be comfortable milling a flat on a piece of round stock with that setup.

2. The stirrup clamp (if that's the right name) that holds the stock in the v-block gets in the way of the drill chuck pretty quickly. Somewhat better if I'm using a collet and a center drill but still not much clearance.

3. How do you ensure that the v-block is square on the table, or put another way, that the vee is parallel to the t-slots and aligned with the milling head?