- Joined

- Feb 1, 2015

- Messages

- 9,604

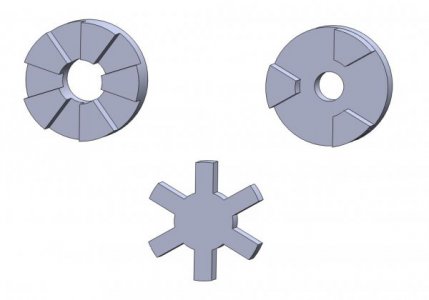

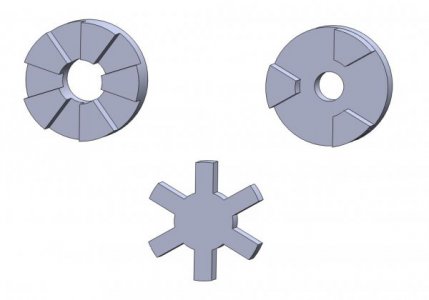

The drive dogs of this type that I have seen have identical geometries for the tooth and the space. Making a five tooth dog would be accomplished by dividing the circle into ten equal sectors with 36º included angles. .This will make both dogs identical and provide the greatest strength.

On the other hand, a Lovejoy flexible coupling uses an elastomeric spider with six legs with parallel sides.

The illustration on the left below would be for a five tooth dog driving an identical dog. The right illustration would be for a Lovejoy type dog using the s[pider below and driving an identical dog.

On the other hand, a Lovejoy flexible coupling uses an elastomeric spider with six legs with parallel sides.

The illustration on the left below would be for a five tooth dog driving an identical dog. The right illustration would be for a Lovejoy type dog using the s[pider below and driving an identical dog.