I am going to pick this mill up and I plan to use some 4x4x1/4" angle iron and some wood 4x4's to make a "pallet" for it. It will be lifted off the ground and I can bolt to the bottom of it.

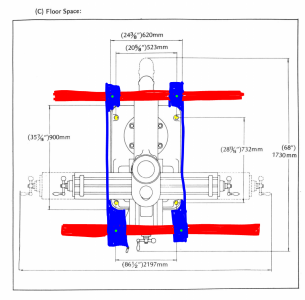

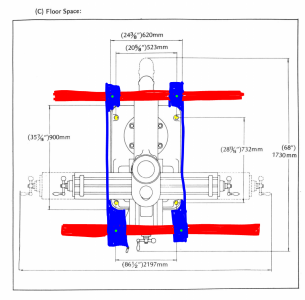

So plan is to put the angle in blue and bolt that to the mill base, and then the 4x4 in red are bolted to that. The drawing from the manual has the bolt centers and I assume they are accurate.

My question is about bolt size to go through the angle and base, how tall is the base, looks to me like I need 5/8"x5" bolts (the yellow dots)?

I plan to use some bigger bolts that will be counter-bored from the bottom of the 4x4 in green. Then after I have it where I want it, I will remove the 4x4 re-use the angle and add adjustable feet (similar to the David Best PM935). At least that is the current plan.

So plan is to put the angle in blue and bolt that to the mill base, and then the 4x4 in red are bolted to that. The drawing from the manual has the bolt centers and I assume they are accurate.

My question is about bolt size to go through the angle and base, how tall is the base, looks to me like I need 5/8"x5" bolts (the yellow dots)?

I plan to use some bigger bolts that will be counter-bored from the bottom of the 4x4 in green. Then after I have it where I want it, I will remove the 4x4 re-use the angle and add adjustable feet (similar to the David Best PM935). At least that is the current plan.

Last edited: