To perform CNC threading on my lathe (Sherline 4400) I needed to add an index the spindle. This would allow Mach 3 to synchronize the carriage advancement with the spindle position. I decided to use a high quality optical sensor for this.

I've thought long and hard on how I should mount this sensor to my machine. Most people just bolt it to a bracket on the lathe mounting base. I however wanted something a bit more elegant.

Below were my design requirements

1. The mount must be mounted to the machine itself and not the base.

2. There should be minimum drilling into the machine

3. The mount must facilitate sensor adjustment fore and aft, left and right

4. All adjustments to the sensor should be done easily with one hand

5. Cable strain relief should be a built in feature of the mount

6. The final product should look elegant like all my designs.

The pictures below are of my final design. The sensor mount attaches to the bottom of the rear half of the spindle belt guard and secured by two threaded plates.

I must thank my beautiful wife for taking these pictures for me since photography is not my forte.

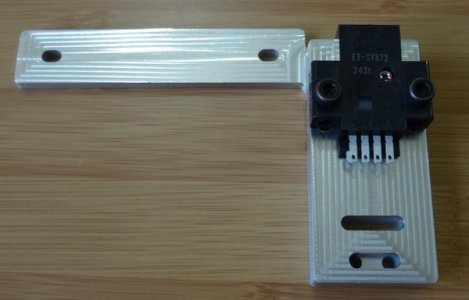

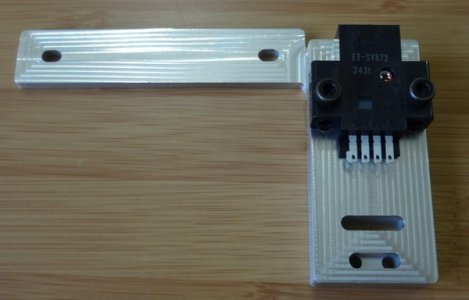

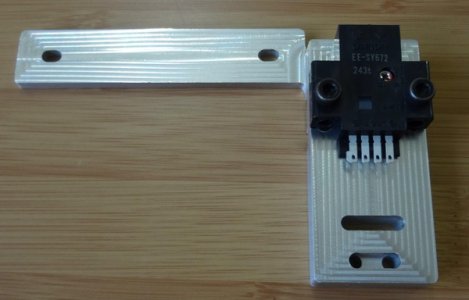

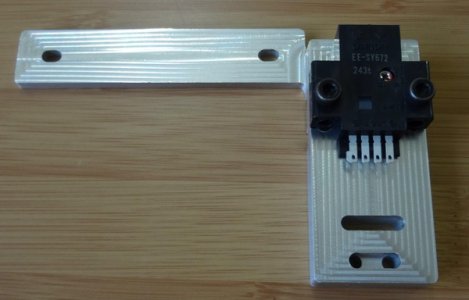

Completed mount with the optical sensor mounted as seen from the rear.

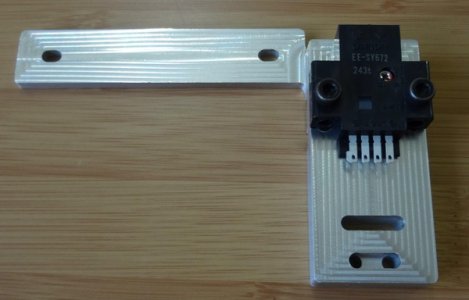

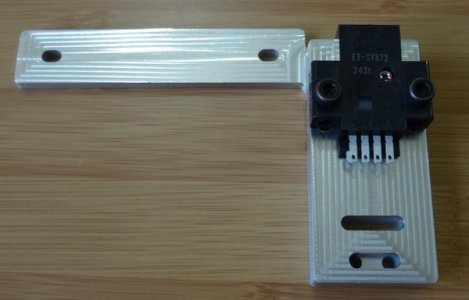

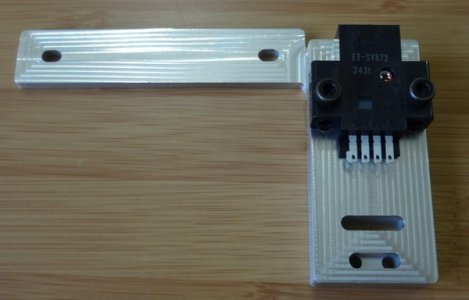

Completed mount with the optical sensor mounted as seen from the front.

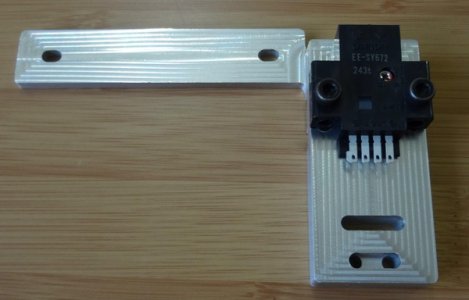

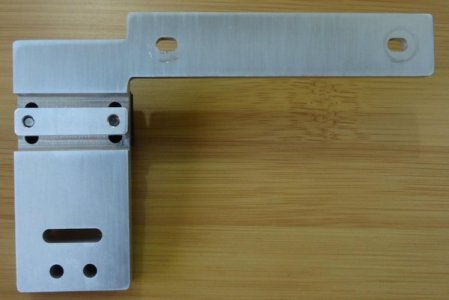

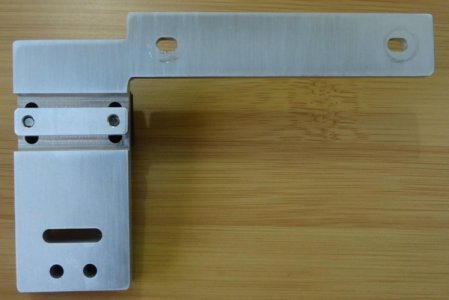

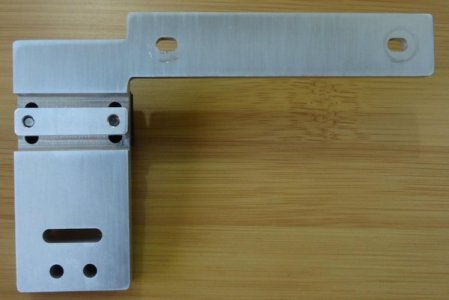

The components of the mount. Going left to right:

1. 2x Mounting plates to secure the mount to the spindle belt guard.

2. Adjustment plate that allows the sensor to be moved back and forth on the mount then locked into its desired position.

3. The mount itself. The long flange fits under the rear half of the spindle belt guard and is bolted in place via two M3 bolts that thread into the mounting plates which fit inside the belt guard.

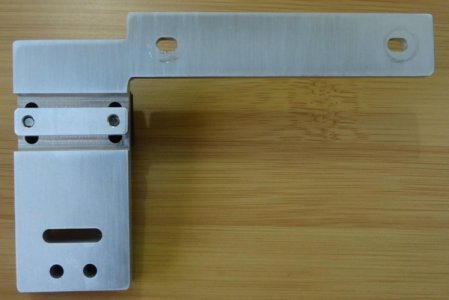

Underside of the mount showing the adjustment/locking plate.

Entire assemble bolted to the rear half of the spindle belt guard.

Sensor and mount fitted to the lathe.

This is a 1/4" 20TPI thread cut from 1/4" 316 Stainless Steel stock. Using a 60 degree carbide insert. The threaded portion is .4" long.

Spindle speed: 1000RPMs

Infeed angle: 29 degrees

Depth of cut for each pass : .005"

Number of spring passes: 1

The machine produced this thread in about a minute.

Its a bit tight with the nut I used to test it on but I'm still very pleased with it as my first attempt.

Chevy

I've thought long and hard on how I should mount this sensor to my machine. Most people just bolt it to a bracket on the lathe mounting base. I however wanted something a bit more elegant.

Below were my design requirements

1. The mount must be mounted to the machine itself and not the base.

2. There should be minimum drilling into the machine

3. The mount must facilitate sensor adjustment fore and aft, left and right

4. All adjustments to the sensor should be done easily with one hand

5. Cable strain relief should be a built in feature of the mount

6. The final product should look elegant like all my designs.

The pictures below are of my final design. The sensor mount attaches to the bottom of the rear half of the spindle belt guard and secured by two threaded plates.

I must thank my beautiful wife for taking these pictures for me since photography is not my forte.

Completed mount with the optical sensor mounted as seen from the rear.

Completed mount with the optical sensor mounted as seen from the front.

The components of the mount. Going left to right:

1. 2x Mounting plates to secure the mount to the spindle belt guard.

2. Adjustment plate that allows the sensor to be moved back and forth on the mount then locked into its desired position.

3. The mount itself. The long flange fits under the rear half of the spindle belt guard and is bolted in place via two M3 bolts that thread into the mounting plates which fit inside the belt guard.

Underside of the mount showing the adjustment/locking plate.

Entire assemble bolted to the rear half of the spindle belt guard.

Sensor and mount fitted to the lathe.

This is a 1/4" 20TPI thread cut from 1/4" 316 Stainless Steel stock. Using a 60 degree carbide insert. The threaded portion is .4" long.

Spindle speed: 1000RPMs

Infeed angle: 29 degrees

Depth of cut for each pass : .005"

Number of spring passes: 1

The machine produced this thread in about a minute.

Its a bit tight with the nut I used to test it on but I'm still very pleased with it as my first attempt.

Chevy