Just wondering what the general pros/cons between the Sherline vs. Taig mills might be. I've been having a little trouble finding a good resource to compare these two and figured I'd ask this group. I'm sure this may have been brought up before and apologize if it has. Thanks

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sherline vs Taig mill

- Thread starter JMBrewer

- Start date

- Joined

- Nov 14, 2016

- Messages

- 3,002

I don't have any hands on experience with the Taig mill, but I do have a Taig lathe and a Sherline lathe and mill.

Speaking in general terms based mostly on the lathes:

Taig seems to excel in making things inexpensively but good. Not in a cutting corners way, more just not making something cost more than it needs to and with the idea that the end user can always upgrade to add features if desired, they do offer many of these upgrades just extra to the basic machine.

Sherline is more refined, better finished, more features on the basic machine but also significantly more expensive. Base model lathe only package for Sherline is $625, same for Taig is about $400 (adding in the cost of a tail stock which is not included on the basic Taig packages).

Both are highly customizable but Taig seems even better suited for those who want to make a custom machine. You can literally buy a Taig one piece at a time, and they are set up for this so it does not become ridiculously expensive. You can also buy most any Sherline part, but it is far more affordable to buy it complete.

Taig is a bit larger, the base Sherline lathe is a 3.5x8" lathe, Taig is a 4.5x9.75" lathe. The Taig mill is substantially larger / heavier at 80lbs vs 30lbs for the base Sherline 5000 mill (Sherline has 3 distinct mill families 5000 series, 2000 series and the 5800 series).

Sherline offers manual, and CNC ready machines up to complete turn key CNC packages including all the hardware, software and even the computer. Taig is a little more build your own for CNC, they offer packages that get you about 80% of the way, but the last bit is on you.

My preference is towards Sherline, but I find Taig has many clever solutions to how they do things. If you want to tinker and make your mill exactly the way you want it Taig has a definite advantage. If you just want to buy it and get to making stuff, Sherline will get you there faster. My experience is that both companies offer very good customer support.

Taig has a pretty dreadful website though, very 1990s Geocites-esqe. They do have a reseller Nick Carter who has a great website, and is a big advocate for Taig. I'd dig through his site and read some of the articles he has posted, maybe even send him an email if you have specific questions. He is active on a Taig forum and seems to be very open to talking to people about Taig machines.

http://www.cartertools.com/

Speaking in general terms based mostly on the lathes:

Taig seems to excel in making things inexpensively but good. Not in a cutting corners way, more just not making something cost more than it needs to and with the idea that the end user can always upgrade to add features if desired, they do offer many of these upgrades just extra to the basic machine.

Sherline is more refined, better finished, more features on the basic machine but also significantly more expensive. Base model lathe only package for Sherline is $625, same for Taig is about $400 (adding in the cost of a tail stock which is not included on the basic Taig packages).

Both are highly customizable but Taig seems even better suited for those who want to make a custom machine. You can literally buy a Taig one piece at a time, and they are set up for this so it does not become ridiculously expensive. You can also buy most any Sherline part, but it is far more affordable to buy it complete.

Taig is a bit larger, the base Sherline lathe is a 3.5x8" lathe, Taig is a 4.5x9.75" lathe. The Taig mill is substantially larger / heavier at 80lbs vs 30lbs for the base Sherline 5000 mill (Sherline has 3 distinct mill families 5000 series, 2000 series and the 5800 series).

Sherline offers manual, and CNC ready machines up to complete turn key CNC packages including all the hardware, software and even the computer. Taig is a little more build your own for CNC, they offer packages that get you about 80% of the way, but the last bit is on you.

My preference is towards Sherline, but I find Taig has many clever solutions to how they do things. If you want to tinker and make your mill exactly the way you want it Taig has a definite advantage. If you just want to buy it and get to making stuff, Sherline will get you there faster. My experience is that both companies offer very good customer support.

Taig has a pretty dreadful website though, very 1990s Geocites-esqe. They do have a reseller Nick Carter who has a great website, and is a big advocate for Taig. I'd dig through his site and read some of the articles he has posted, maybe even send him an email if you have specific questions. He is active on a Taig forum and seems to be very open to talking to people about Taig machines.

http://www.cartertools.com/

Last edited:

Good explanation Aaron.

And I really liked your take on the fact that Taig is a good choice for those who like to tinker with their machines. I say that because I was drawn towards Taig and I absolutely love to tinker with my stuff.

And I really liked your take on the fact that Taig is a good choice for those who like to tinker with their machines. I say that because I was drawn towards Taig and I absolutely love to tinker with my stuff.

Last edited by a moderator:

- Joined

- Nov 14, 2016

- Messages

- 3,002

Good explanation Aaron.

And I really liked your take on the fact that Taig is a good choice for those who like to tinker with their machines. I say that because I was drawn towards Taig and I absolutely love to tinker with my stuff.

Taig seems to cater to those who want to tinker to make it just how they want it. Not tinker just to make the thing work like some of the Chinese mini-lathes. Taig is less expensive, not "cheap" there is a difference.

Last edited by a moderator:

- Joined

- Feb 15, 2020

- Messages

- 375

One obvious difference between the Sherline and Taig machines is the motor and speed control. Sherline has a continuously variable speed DC motor where Taig uses a single speed motor with stepped pulleys. It's a matter of preference which is the better solution.

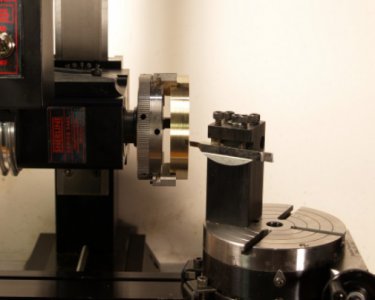

Another feature I've found very useful with Sherline is being able to rotate the headstocks. That can allow machining of parts that are too large for the lathe or mill in their normal configurations, horizontal milling, or making complex angles.

Then there are the accessories.

Another feature I've found very useful with Sherline is being able to rotate the headstocks. That can allow machining of parts that are too large for the lathe or mill in their normal configurations, horizontal milling, or making complex angles.

Then there are the accessories.

Attachments

- Joined

- Nov 14, 2016

- Messages

- 3,002

One obvious difference between the Sherline and Taig machines is the motor and speed control. Sherline has a continuously variable speed DC motor where Taig uses a single speed motor with stepped pulleys. It's a matter of preference which is the better solution.

Another feature I've found very useful with Sherline is being able to rotate the headstocks. That can allow machining of parts that are too large for the lathe or mill in their normal configurations, horizontal milling, or making complex angles.

Then there are the accessories.

Also the calibrated handwheels on the lead screw and cross slide. The Taig lathe only has a calibrated wheel on the cross slide with larger graduations. On the other side the standard Taig lead screw allows the carriage to disengage and slide for rapid movement, vs hand cranking all the way with Sherline.

It is apparently pretty common for Taig users to buy a Sherline motor and speed control.

As far as accessories it is nice that both use a 3/4"-16 spindle so with just a little modification you can use accessories from both on either. Taig tooling is much cheaper than Sherline, but again a case of good enough vs highly finished. The Taig 3 jaw chuck is around $75 but requires the user to finish the jaws on the lathe to give it a precise fit. Sherline's 3 jaw is $150 but comes ready to go.

I personally prefer the Sherline lathe, but I can definitely see the appeal of the Taig.

I just finished mounting my DC 300 watt motor on my little Taig. It’s sweet.

PS…plus, I really didn’t like those little micro V-belts so I went with Urethane 5mm belting. Just 2 steps on my pulley so I can get up to 5000 RPM if I want or just leave it so it averages around 3500 max RPM with a little more torque than the 5000 RPM set up. At least that’s the game plan. Time will tell

PS…plus, I really didn’t like those little micro V-belts so I went with Urethane 5mm belting. Just 2 steps on my pulley so I can get up to 5000 RPM if I want or just leave it so it averages around 3500 max RPM with a little more torque than the 5000 RPM set up. At least that’s the game plan. Time will tell

Attachments

Last edited:

I have no experience using a Sherline mill, but I do have the Taig manual mill. One big difference between the two is that the Taig has a steel frame. Fit and finish is fine. The Sherline is aluminum. It’s lighter and generally considered less rigid. You can easily mount the Taig headstock horizontally if you need. I’ve done this in order to mill the block on an antique Briggs & Stratton engine. It definitely pushed the working envelope, but worked just fine. All three axis do have graduated dials. The x axis movement is 12”, the y is 6”, and the z is 6”I just finished mounting my DC 300 watt motor on my little Taig. It’s sweet.

PS…plus, I really didn’t like those little micro V-belts so I went with Urethane 5mm belting. Just 2 steps on my pulley so I can get up to 5000 RPM if I want or just leave it so it averages around 3500 max RPM with a little more torque than the 5000 RPM set up. At least that’s the game plan. Time will tell

their accessories are certainly more affordable than Sherline’s, though I am impressed with their quality. Taig is a smaller company, but the customer support has been excellent.

Thats been my experience.

- Joined

- Feb 17, 2013

- Messages

- 4,406

I just bought a Taig 2019CR mill ... CR apparently stands for "Computer ready," but it does not include stepper motors or a stepper controller. I got those from Amazon. I'm planning on building out a complete CNC mill (based on aCentroid Acorn CNC controller, etc. and an enclosure based on 80/20 1" extrusions and Lexan panels.) for a customer of mine

Might take me a couple months, because I still have a strength/coordination issue with my left hand (due to a stroke last November). I'll continue to post progress reports as things get done.

PS#1 - I livein Chandler, AZ, just 4 1/2 miles away from Taig. So instead of having it shipped, I went there to pick it up. They gave me a nice discount, because they saved $ on packing and shipping.

PS #2 - While looking for somrthing else, I stumbled on a Walmart web page, where they sell stepper controllers, etc:

ttps://www.walmart.com/ip/Stepper-Motor-Driver-Seven-Micro-Steps-Motor-Driver-For-0-5-4A-32-Microstep-160W-DC-9-40V/1961068691?athbdg=L1700

The least expensive stepper controllers I could find at Amazon were around $21. Walmart's are just a little bit above $13.

Might take me a couple months, because I still have a strength/coordination issue with my left hand (due to a stroke last November). I'll continue to post progress reports as things get done.

PS#1 - I livein Chandler, AZ, just 4 1/2 miles away from Taig. So instead of having it shipped, I went there to pick it up. They gave me a nice discount, because they saved $ on packing and shipping.

PS #2 - While looking for somrthing else, I stumbled on a Walmart web page, where they sell stepper controllers, etc:

ttps://www.walmart.com/ip/Stepper-Motor-Driver-Seven-Micro-Steps-Motor-Driver-For-0-5-4A-32-Microstep-160W-DC-9-40V/1961068691?athbdg=L1700

The least expensive stepper controllers I could find at Amazon were around $21. Walmart's are just a little bit above $13.