- Joined

- Apr 8, 2013

- Messages

- 1,979

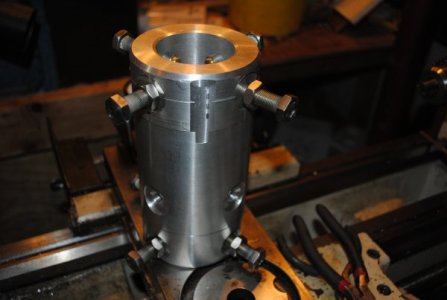

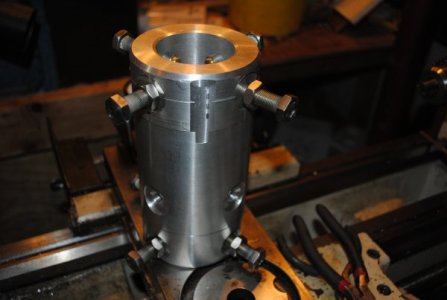

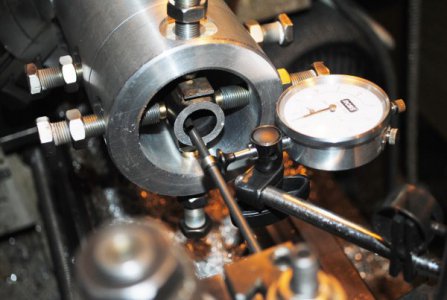

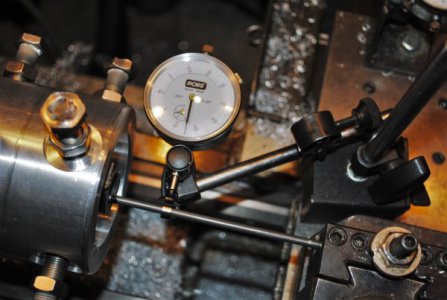

I had put this in another thread but thought it would be better here. I'm starting a short barreled smokeless muzzle loader build that won't reach my outboard spider. My son had a 4 inch hunk of solid 6061 laying around so I decided to build a fixture like I've seen elsewhere on line. I have 3 rows of holes. The first 2 rows are 2 1/2 inches apart for bolt work and barrel stubbing. The first and last rows of holes are 7 inches apart for holding rifle barrels. My outboard spider on my Grizzly G4003G requires at least a 22 inch barrel length or it can't be used. As this is going to be a stub job, I also needed a fixture that would allow me to dial in something only 3 inches long. The bolts are made from allthread 1/2 x 20 rod. The bolt heads are nuts TIG'd on and the brass tips are pressed in. I love 20 pitch because each complete turn is .050 inches.