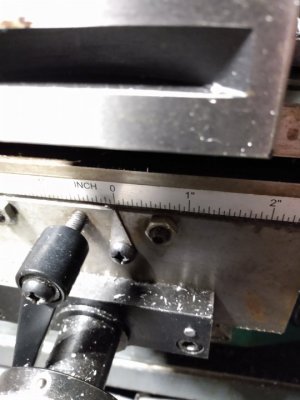

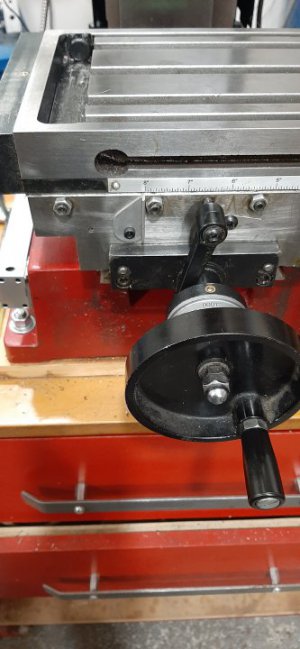

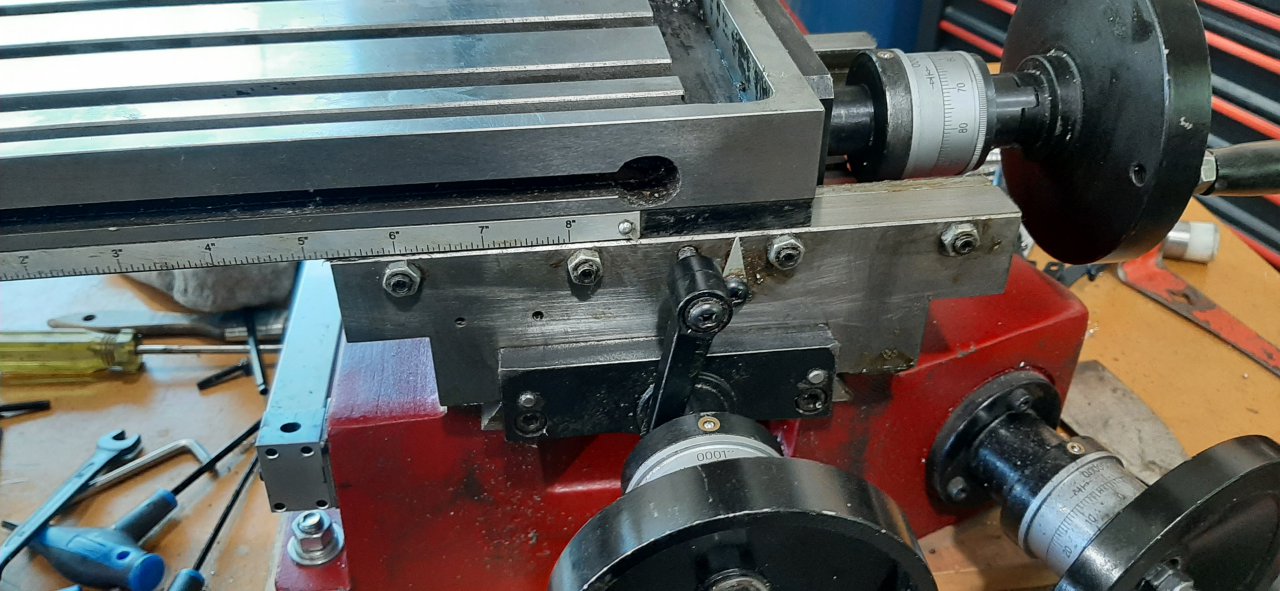

I have to swallow my pride here and ask a question that might have an obvious answer. I am installing a DRO onto a Sieg X3 mill that I have had for about 10 or more years. I have noticed that the table slides further one way than the other, about 2 ". The table has a ruler on the front for rough measurements and the pointer goes past the rule at one end, and not to the other end. Yes, I can move the pointer. The table work surface is about 21 inches long and the base is about 8 inches wide so the table edges would be inboard on both ends if it was centered.

I had it all apart today. I cannot figure out, with the way they did the mechanics, how I can be off that much. But, would not be the first time I can't see the forest for the trees....

I had it all apart today. I cannot figure out, with the way they did the mechanics, how I can be off that much. But, would not be the first time I can't see the forest for the trees....