- Joined

- Nov 1, 2018

- Messages

- 98

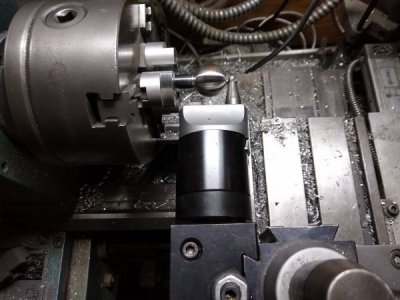

As many of other hobby machinists I bought a QCTP kit including different types of tool holders.

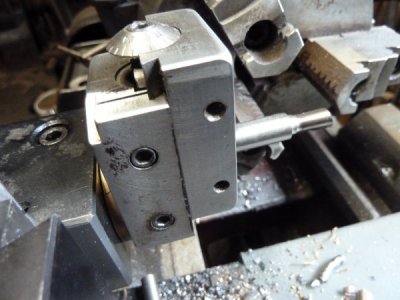

The one of the most rarely used holders is a Heavy Duty Boring one for 3/4" bar shank. I typically don't use large boring bars like that, so this holder just stays on a shelf. But recently I realized I can build a raduis turner tool with it.

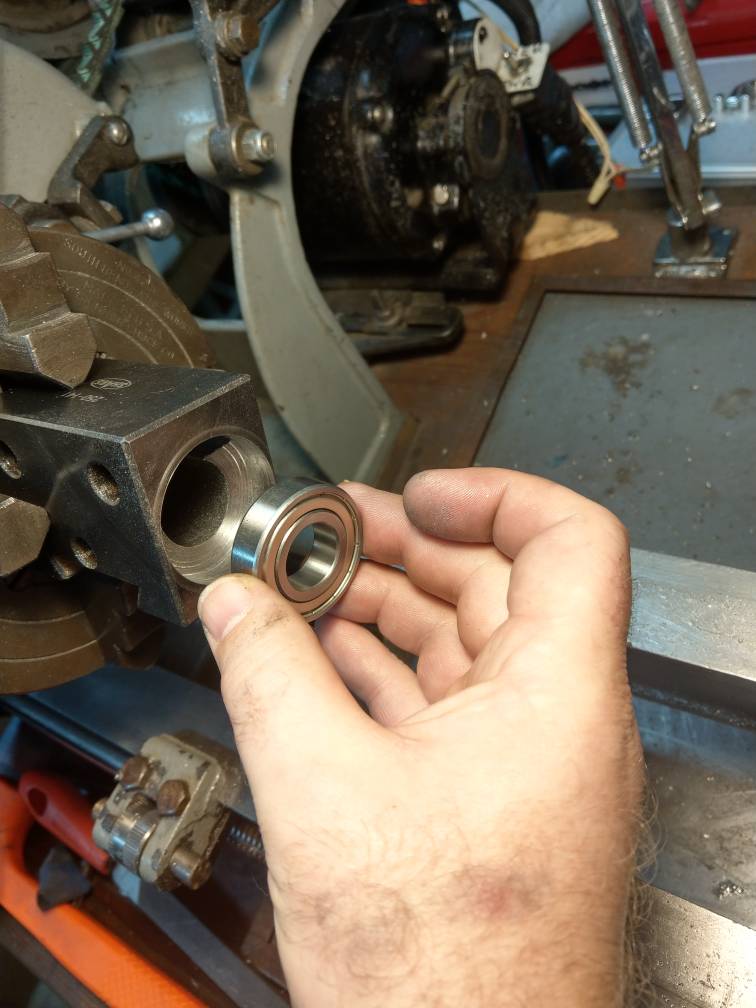

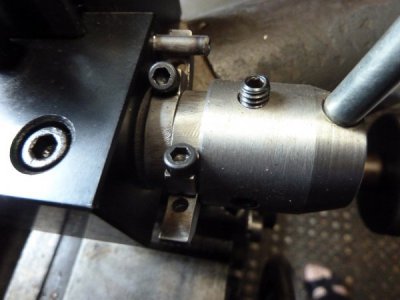

I think it looks pretty clear. I've got 3/4" OD, 5/8" ID bronze bushings perfectly fitting into 3/4" boring bar holder. The straight shank boring head arbor with 5/8" shank fits inside the bushings. I use thrust roller bearings and 3/8-16 bolt and nuts to pre-load the arbor/spindle. The only part I've made from scratch was an aluminum washer in between of thrust bearings and nuts. CCMT-0602 insert holder was made for one of the previous projects.

The one of the most rarely used holders is a Heavy Duty Boring one for 3/4" bar shank. I typically don't use large boring bars like that, so this holder just stays on a shelf. But recently I realized I can build a raduis turner tool with it.

I think it looks pretty clear. I've got 3/4" OD, 5/8" ID bronze bushings perfectly fitting into 3/4" boring bar holder. The straight shank boring head arbor with 5/8" shank fits inside the bushings. I use thrust roller bearings and 3/8-16 bolt and nuts to pre-load the arbor/spindle. The only part I've made from scratch was an aluminum washer in between of thrust bearings and nuts. CCMT-0602 insert holder was made for one of the previous projects.