Hi there,Heiko,

The Metric trans-positioning gear pair that Atlas used in their tables are 52 and 44. Which happen to be included in the standard set of change gears that shipped with all of the Atlas and Atlas-Craftsman 6" lathes. So I wouldn't buy the 47/37 pair because (a) you should already have the 52/44 pair and (b) the 47/37 pair wouldn't match the Atlas metric threading tables.

The one extra original that I have of the 1954 Atlas MOLO cost me $54.50 plus postage. As I've written elsewhere, the average price of MOLO's on eBay is about $35.00. I wouldn't have paid that much for one except that at the time it was one of the few that I hadn't yet acquired. I was in a little bit of a rush to complete the MOLO history that I was writing and that issue was one of the few that I still didn't have. If you want it, fine. Send me a PM with your name and address. If you don't want it, no response is necessary.

Alternatively, you can set up a search on eBay as I did, although you can expect a lot of false hits as eBay is more interested in selling stuff than they are in someone finding what they were really looking for. But it may take you quite a while to find what you are looking for as most eBay sellers are clueless as to what keywords to use. About the only thing that most of them will do is to include a photo of the Copyright Page and the front cover. Beginning in 1954, Atlas began including the print history between 1937 and the year that the particular copy was printed. So you would be looking for 1954, 1955 or 1957. And it really doesn't matter whether the front cover is a gray Atlas one or a black Craftsman one as in any year from 1954 on, the only difference between the two versions were the covers. FYI, between about 1939 and 1953, all covers were black Atlas ones. And probably only one year did a few of the ones printed cover the 618. In 10 years of looking, only twice have I found one Copyright 1937 that covered the 618. I don't know whether or not they ever printed one that covered the 101.07301, although I am still looking.

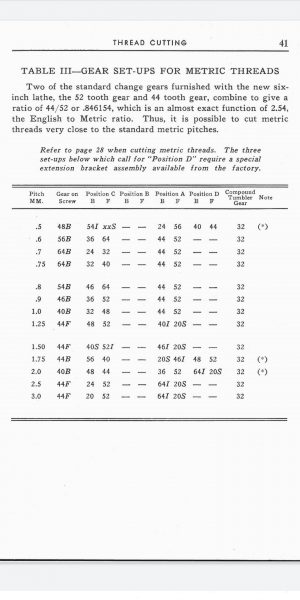

I got a PDF of the molo that covers metric for the 6 inch lathe but a couple of standard metric thread pitches are only doable with gears at the D position. The Chang gear bracket in my lathe doesn't have the D position. In the manual it states that an extension bracket is available from the factory. I wonder if I can still find one today (40 years later) and what that would look like.

See the picture, in the text above the chart it talk about the D position.

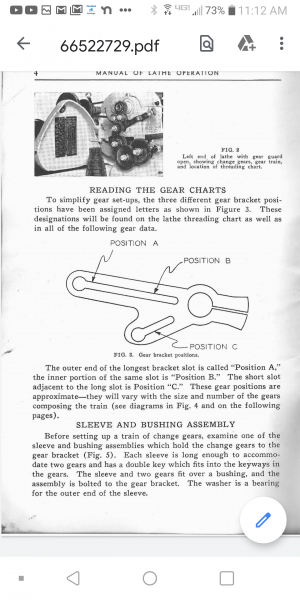

The other picture shows what my gear change bracket looks like. No D position.

Thanks for your advice,

Heiko